Schedule a Call Back

Autoform Hydro 2016 Springback Compensation In Tube Hydroforming

Autoform Hydro 2016 Springback Compensation In Tube Hydroforming

AutoForm Engineering GmbH, the leading supplier of software solutions for the sheet metal forming industry, has unveiled its latest software AutoForm Hydro 2016. This version of AutoForm Hydro has many significant enhancements including a completely new unique set of functionalities for springback compensation. Based on accurate springback simulation results, AutoForm Hydro 2016 allows for efficient springback compensation after bending and hydroforming operations.

AutoForm Hydro is AutoForm’s state-of-the-art solution for rapid tool design for tube hydroforming processes as well as for the simulation of these processes. The latest software version, AutoForm Hydro 2016, offers new functionalities and significant enhancements. The most important one is springback compensation of bending and hydroforming operations.

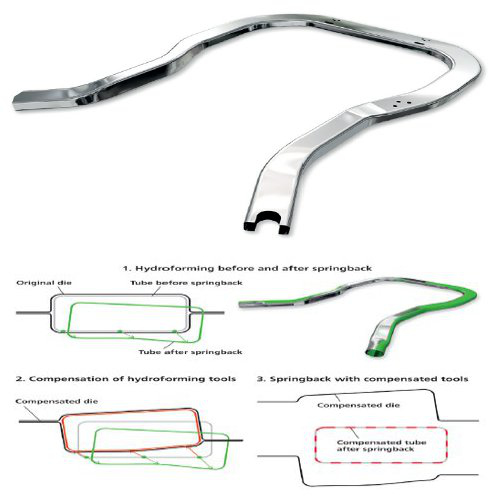

The bending compensation is achieved through the generation of a new bending line using the same springback value in the opposite direction and compensation of process parameters while the tool geometries remain unchanged. The hydroforming compensation takes into account springback after the hydroforming operation and all springback modes such as translation, twisting and crowning. The automatic update of tool geometries results in compensated tools, which can be easily exported. By identifying and analysing the root cause of springback, engineers are able to define the most effective compensation strategy for the project at hand.

In addition to this new and unique functionality in tube hydroforming, AutoForm Hydro 2016 also provides enhancements in process description and tool design such as force controlled axial tools for bending and hydroforming operations, appropriate positioning before bending operation, generation of fillet radius for upper and lower dies as well as volume controlled hydroforming. The comprehensive in-depth understanding and validation of the entire hydroforming process leads to shorter development time and reduced tooling, material and production costs.

Dr Markus Thomma, Corporate Marketing Director of AutoForm Engineering, stated: “AutoForm Hydro 2016 enables our users to reach a new level of competitiveness in tube hydroforming. This is the only software on the market today, which allows for springback compensation in tube hydroforming. The ability to carry out feasibility, springback calculation and its compensation already in the process engineering stage reduces additional costly efforts for redesign in the CAD stage and results in significant time savings in tool making and tryout. With AutoForm Hydro 2016, part designers, process engineers as well as tool and die makers are well-equipped to meet the increasing demands in terms of part complexity, ever higher part quality requirements, implementation of new materials as well as ever shorter lead times and higher cost pressures.â€

AutoForm offers software solutions for the die-making and sheet metal forming industries along the entire process chain. The company is recognised as the leading provider of software for product manufacturability, tool and material cost calculation, die face design and virtual process optimisation. All of the Top 20 automotive OEMs and most of their suppliers have selected AutoForm as their software of choice. Besides its headquarters in Switzerland, AutoForm has offices in Germany, The Netherlands, France, Spain, Italy, USA, Mexico, Brazil, India, China, Japan and Korea.