Schedule a Call Back

Auto Parts Vision Inspection System

Auto Parts Vision Inspection System

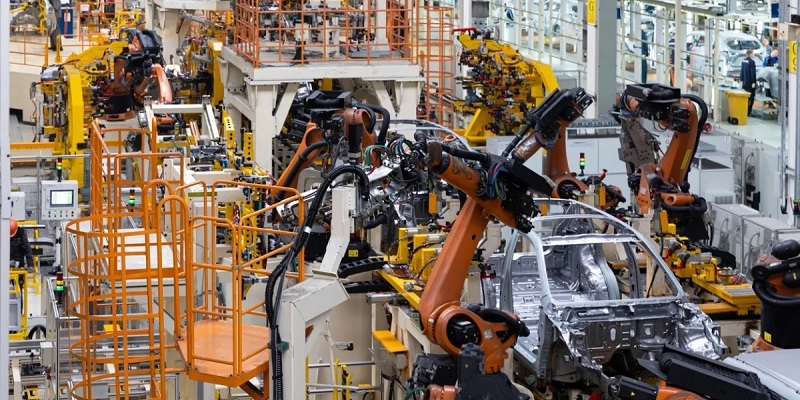

A manufacturer of components for the automotive industry needed an automated solution to labor intensive process. Vision Inspection systems can perform repetitive tasks faster, more accurately, and with greater consistency over time than humans.

Product & Technology News

| Description | Parameter |

|---|---|

| No. of Camera | 1 to 5(Optional) |

| Vision System | High resolution lenses and light source |

| Software | Accuvision Pro |

| Speed | 200 ~ 1000 pcs/min |

| Lights | LED Lights with auto on/off |

| Part Feeding | high speed conveyor,Vibratory feeder and bowl |

| Operating system | WINDOWS XP/7/8.1 |

| Weight | 750 kgs |

| Accuracy | 0.010mm |

| Size | 2.1 X 1.4 X 1.9 Meter |

- Auto Parts Vision Inspection System, with easy to Check Presence/Absence of part on Object.

- Auto Parts Vision Inspection System, with easy to use standard software, are leading the way toward zero defect quality.

- Auto Parts Vision Inspection System can be used to inspect Nuts,rods,washer fastener,O-ring,special parts.

- Auto Parts Vision Inspection System check Cut on Outer Profile.

- Optional cameras are available to check for internal threads and surface imperfections.

- Vision can be added to detect defects like missing internal threads, nylon ring presence, and missing crimp.

- Auto Parts Vision Inspection System can find Visual and dimensional defects.

- Windows based software makes part setup easy, and allows for part storage and retrieval.

- Developed software as per indian market requirement

- User Friendly