Schedule a Call Back

Power Components

Power Components

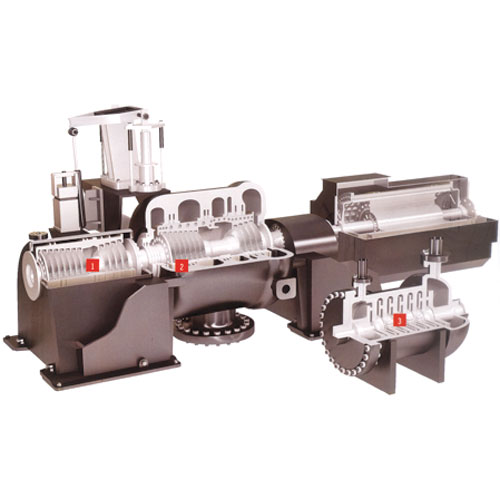

Seco Tools India (P) Ltd offers turbine power components.

- Highlights of these products are rotor shaft and disc: responsible for transferring gas or steam energy into the generator, the rotor shaft and discs can take the form of a single component or an assembly.

- Steam systems typically incorporate a monolithic component made of carbon steel, while gas turbines usually demand an assembly with both carbon steel and heat resistant superalloy components.

- In either instance, manufacturers face challenging features to machine and heavy duty metal cutting. Casing: while the variety of turbine types result in different shapes and designs of casings, these components always provide a shell that contains and controls the working gas. Typically produced from castings of nodular cast iron or low alloy steel, turbine generator casings usually require substantial material removal, offering high potential for time and cost savings through process improvement. Impeller: Typically made from low-alloy or stainless steels, impellers play a central role in the centrifugal compressors in gas turbines. An impeller's design typically comprises a short cylinder with an inlet to accept incoming fluid, vanes to push the fluid radially and a splined, keyed or threaded bore to accept a drive shaft.

- The components incorporate thin walls and require use of very long tool overhangs, making them especially challenging to machine effectively. Generator shaft: Forming the mechanical core of a turbine generator, the generator shaft typically is machined from a carbon steel alloy and produced from a forged shaft. The component requires heavy duty turning, as well as substantial milling processes, including disc milling of long deep slots.