Schedule a Call Back

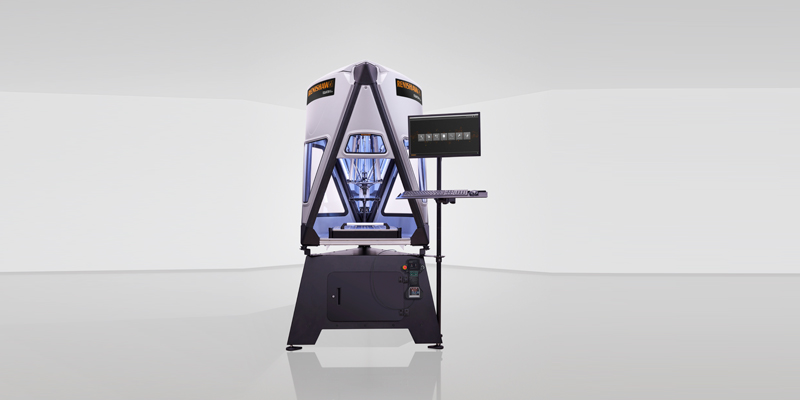

Fasteners Inspection System

Fasteners Inspection System

Fasteners Inspection System is  high speed, 100% measuring and sorting fastener inspection systems. The Fasteners Inspection System  enables highly precise 2D and/or 3D measurements, of high volume parts and components before they are introduced into production.Fasteners Inspection System  will help with eliminating costly process jams and malfunctions

Product & Technology News

| Description | Parameter |

|---|---|

| No. of Camera | 4 |

| Vision System | High resolution lanses and light source |

| Software | Accuvision Pro |

| Speed | 200 ~ 1000 pcs/min |

| Operating system | WINDOWS XP/7 |

| Weight | 750 kgs |

| Accuracy | 0.010mm |

| Size | 2.1 X 1.4 X 1.9 Meter |

- Fasteners Inspection System , with easy to use standard software, are leading the way toward zero defect quality.

- Fasteners Inspection System  can be used to inspect Nuts,rods,washer fastener,O-ring,special parts.

- Optional cameras are available to check for internal threads and surface imperfections.

- Vision can be added to detect defects like missing internal threads, nylon ring presence, and missing crimp.

- Fasteners Inspection System allows great detail of I.D. threads and the detection of very small defects like; Chips in threads, weld splatter, a single damaged thread, torn threads, reamed threads, short or missing thread(s).

- Windows based software makes part setup easy, and allows for part storage and retrieval.

- Developed software as per indian market requirement

- Run on Very High Speed FPGA based Motion Control Card and other controller

- User Friendly