Schedule a Call Back

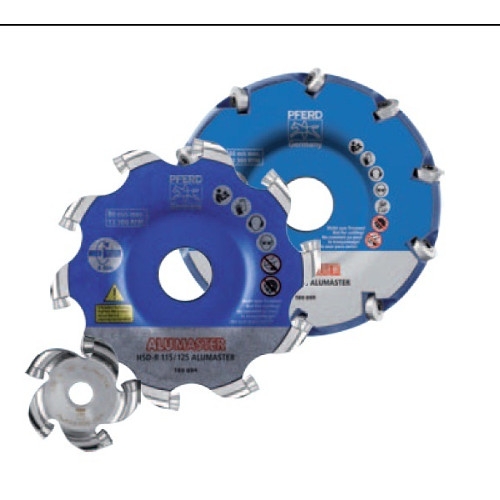

Alumaster High Speed Disc

Alumaster High Speed Disc

SWIT offers PFERD's ALUMASTER high speed disc - a unique tool with an extremely high stock removal rate..

Product & Technology News

- Alumaster high speed disc is ideal for processing aluminium as it does not generate hazardous or explosive dust. It consists of specially developed tungsten carbide cutting inserts, which are fixed to the high speed disc.

- It does not require an extraction system.

- It is a cost-effective and eco-friendly alternative to grinding wheels and flap discs of comparable weight.

- It has innovative and robust cut geometry, ie the highest degree of safety, extreme durability, and comfortable work.

- It comes with specially developed, turnable and replaceable tungsten carbide cutting inserts.

- Materials that can be worked are aluminium alloys; brass, copper, zinc; bronze; plastics; and fibre-reinforced duroplastics (GRP, CRP).

- Alumaster high speed disc finds applications in industries such as shipbuilding and yacht construction; wagon construction; silo and container construction; and vehicle construction.

- The tool has primarily been designed for use on aluminium, wrought aluminium alloys and cast aluminium.Â

- Non-ferrous metals with a relatively low strength and fibre-reinforced plastics can also be machined.Â

- This must be checked for the specific application on a case-by-case basis.

- This Alumaster high speed disc HSD-F at an angle of 5–30°, or up to 60° in special cases.

- Do not push the tool deep into the workpiece. The milling disc is not a cutting tool.

- This Alumaster high speed discs for long fatigue-free and resource-saving work with perfect results in a very short period of time.

- This recommends Alumaster high speed discs for long fatigue-free and resource-saving work with perfect results in a very short period of time.

Â