Schedule a Call Back

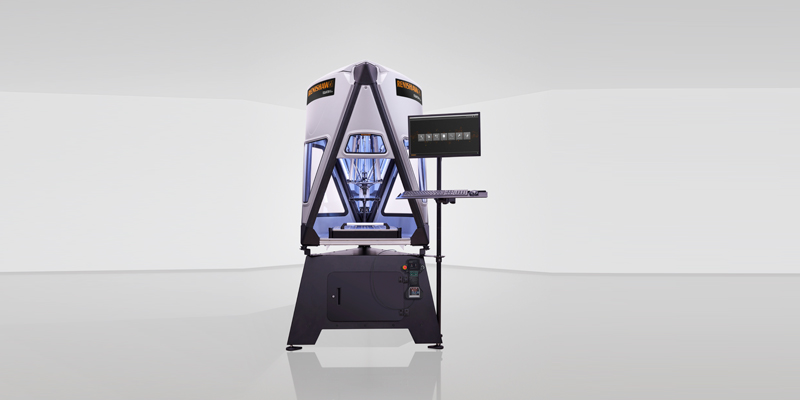

2-D Inspection System

2-D Inspection System

Interface offers a range of systems for inspection of components. Where typically users have to use expensive coordinate measuring machines to inspect components, low cost automation has helped in lowering the cost of inspection. By eliminating the 3rd axis, and using a lower cost high-tech DRO, the inspection requirements of users can be met. The inspection systems consist of 2 linear axis (X and Y) mounted using linear bearings-a fixed probe (pointer) is fixed on a 100-mm travel Z axis. The X and Y axes have linear scales or rotary encoders mounted on them. The system can be mounted on any existing surface plate. The slide unit with a fixed probe is moved and point co-ordinates are recorded by the user using the DRO. The DRO has facility to compute distance and radius. Special programs for automatically measuring centre distance between 2 holes are also provided. Sizes available are 300 x 300, 600 x 300 and 600 x 600 mm with an accuracy of 20 microns using linear scales and 75 microns using rotary encoders. Typical applications include profile checking for panels, sheet metal parts, plastic components, engineering and automobile components.