Schedule a Call Back

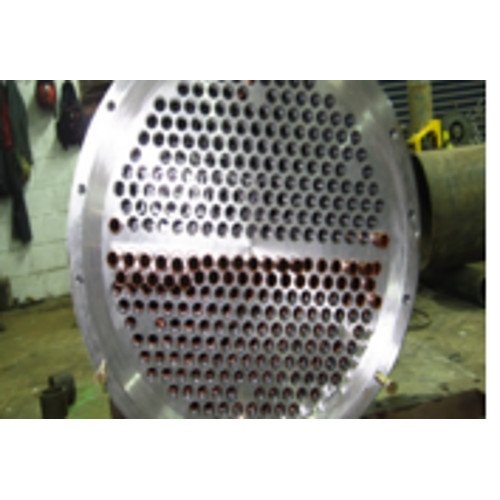

U Tube Bundle Heat Exchangers

U Tube Bundle Heat Exchangers

Asme Heat Exchangers And Vessels offers U Tube Bundle Heat Exchangers. A heat-exchanger system consisting of a bundle of U tubes (hairpin tubes) surrounded by a shell (outer vessel); one fluid flows through the tubes, and the other fluid flows through the shell, around the tubes.Multitherm can duplicate any existing bundle to include dimensions, materials and performance. we can build "U" tube bundles, straight tube "floating" tube bundles, or they can retube fixed tubesheet heat exchangers when the bundles is not removable. multitherm is not locked into any one material. Most bundles tend to be build with copper tubes and steel tubesheets. There can be many variations on the shell and tube design. Typically, the ends of each tube are connected to plenums (sometimes called water boxes) through holes in tubesheets. The tubes may be straight or bent in the shape of a U, called U-tubes.In nuclear power plants called pressurized water reactors, large heat exchangers called steam generators are two-phase, shell-and-tube heat exchangers which typically have U-tubes. They are used to boil water recycled from a surface condenser into steam to drive a turbine to produce power. Most shell-and-tube heat exchangers are either 1, 2, or 4 pass designs on the tube side. This refers to the number of times the fluid in the tubes passes through the fluid in the shell. In a single pass heat exchanger, the fluid goes in one end of each tube and out the other.Surface condensers in power plants are often 1-pass straight-tube heat exchangers (see Surface condenser for diagram). Two and four pass designs are common because the fluid can enter and exit on the same side. This makes construction much simpler. Advantages: One of the big advantages of using a shell and tube heat exchanger is that they are often easy to service, particularly with models where a floating tube bundle (where the tube plates are not welded to the outer shell) is available. Can also be used on fixed tube sheet heat exchangers.

Product & Technology News

- One of the most common applications is the cooling of Hydraulic Fluid and oil in engines, transmissions and hydraulic power packs.

- With the right choice of materials they can also be used to cool or heat other mediums, such as swimming pool water or charge air.

Â

- The simple design of a shell and tube heat exchanger makes it an ideal cooling solution for a wide variety of applications.

Products from Asme Heat Exchangers And Vessels

Shell And Tube Heat Exchangers

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads