Schedule a Call Back

Balluff Transducers for partial-stroke testing on hydraulic valve drives

Useful Information

Useful Information- Oct 12,15

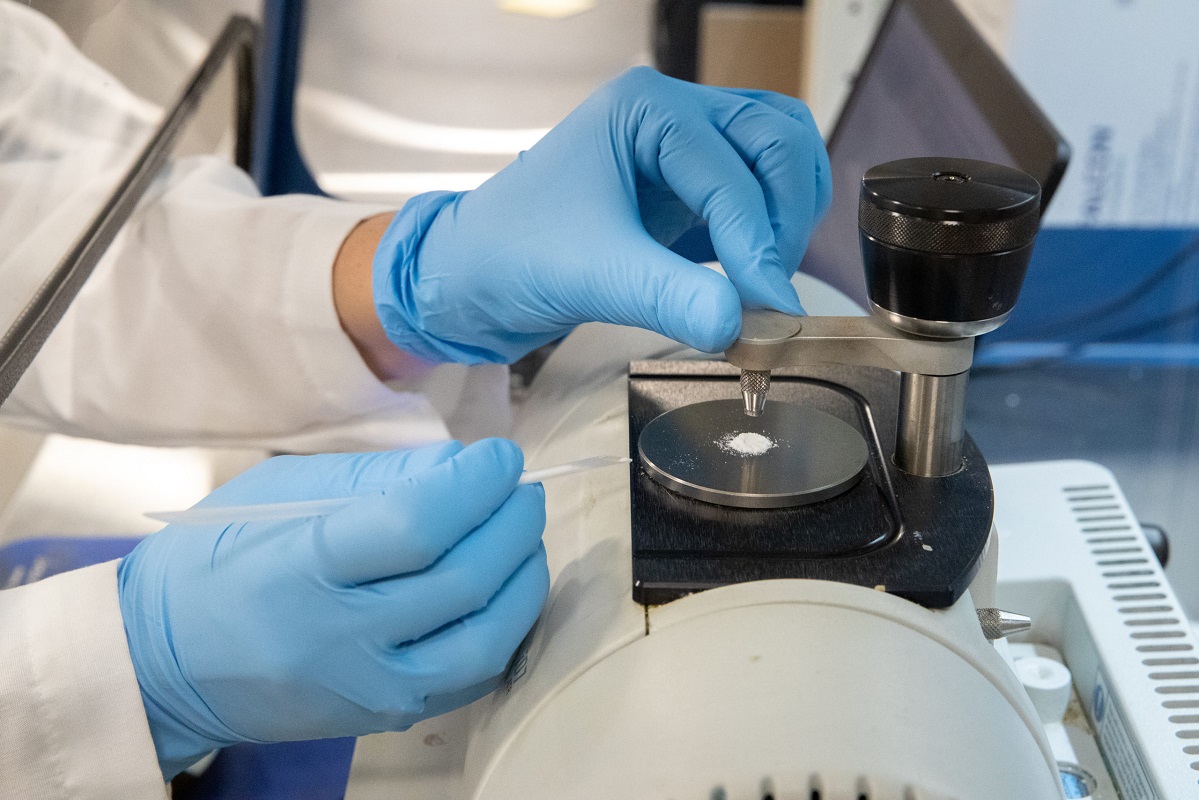

Neuhausen, October 08, 2015 – Balluff GmbH has launched Micropulse® Transducers for partial-stroke testing on hydraulic valve drives. One ideal application area for Micropulse transducers in a rod housing is providing position feedback for hydraulic cylinders in valve drives. They are therefore often located in linear-activated fixtures like stop valves or seat valves, but also in ball valves and shutoff gates with swivel activation in combination with special drive mechanisms (such as Scotch yoke, rack-and-pinion drive, etc.). Partial-stroke testing of cylinders opens up another area of application in combination with the diagnostic options of smart position regulators. Using the absolute signal, the operating suitability of the valve can be monitored during ongoing operation, between the tests already scheduled during downtime. This results in fewer service interruptions and unscheduled stoppages for the system operator. Models with Ex approval are regularly used in explosive atmospheres, found in the Oil & Gas industry and in power plants.

Micropulse transducers work without making any contact and are entirely wear-free and maintenance-free, providing the user with an extremely long service life. For measuring the position feedback of a valve, the transducer is installed on the back end of the drive cylinder. The actual sensor element is installed into a hole that runs lengthwise, passing through the piston and the cylinder rod and reaching over the entire mechanical stroke length. A magnet ring, located in an indentation on the end face of the piston, acts as the position encoder.

Logging the speed of the valve movement over time allows the user to detect wear, corrosion or abrasion in the valve before they worsen and cause negative effects. Common symptoms of pending malfunction may include such aspects as the valve reacting slowly or with a delay, or its required deflection is not completely achieved.

Explosion proof models of Micropulse transducers from Balluff are some of the few position-feedback devices on the market that not only have all basic certifications from start to finish, such as ATEX (EU), IECEx (international), NEC (US), CEC (Canada), but also additional regional qualifications for India, Japan, and Korea. Not only does this simplify the design and global sale of standardized systems, it also helps to prevent expensive errors in the project planning phase.

Related Stories

US tariffs on China causing container and space shortages; India scrambles

US tariffs on Chinese goods come into effect from August 1.

Read more

CDSCO shuts down 36% of drug manufacturing units for failing quality standards

India has around 10,000 pharma manufacturing units, of which nearly 80 per cent are micro-small and medium-scale facilities.

Read more

Pepperl+Fuchs enhances efficiency in intralogistics

Automation is becoming a cornerstone, with significant investments in smart factories and digitalisation to streamline operations and reduce lead times.

Read moreRelated Products

Plain Bushing and Bearings

BMD Precision Bearings LLP offers a wide range of plain bushing and bearings

Industrial Cyclones

Protector Fire & Safety India Pvt Ltd offers a wide range of industrial cyclones.

Impact Crusher

Crush Power offers a wide range of impact crusher.