Schedule a Call Back

Welding trainer for robot programmers

Technical Articles

Technical Articles- Mar 17,15

Virtual Welding Robotics by Fronius is now available to instructors to assist the training of robot programmers. Thanks to this simulation platform, trainees from the field of robotic welding can now get even closer to the action without the limitations imposed by safety devices or missing welding equipment. The system shows the user whether they have programmed the robot correctly or if the welding torch was handled in the right way. A virtual instructor provides specific instructions as to which corrective movements should be made if the system identifies deviations from the ideal torch guidance. In a subsequent simulated step, the weld seam can be illustrated to visually assess the welding result. The data gathered in the training session can be saved to document progress and stored for further analyses. As such, robot programmers can quickly develop a greater sense of the effects of their programming actions and understand how robotic movements affect the welding result.

Virtual Welding Robotics provides further education and training centres with an efficient and convenient way of giving robot programmers a basic understanding of the requirements of robot-assisted welding without having to procure the production equipment. Thanks to the system, carrying out training in a normal classroom environment is possible. The only prerequisite is a functioning robot. Other components of the system are a computer-based training device featuring an integrated touchscreen, a realistic welding torch and dummy workpieces for a wide range of weld seam profiles and welding positions.

In the training sequence, the welding simulator constantly monitors the position of the welding torch on the robot arm, while the robot executes the taught-in movement. The "Ghost" virtual instructor continuously provides visual and acoustic information on the welding speed, the distance to the workpiece (dummy) and the tilt angle of the welding torch that has to be maintained. Deviations from the ideal values are indicated in yellow or red, following the traffic-light system.

The entire welding sequence - including correction notes - is recorded and made available for playback, allowing the trainees to analyse the welding process together with the instructor and come up with ways to optimise the robot programming. All results are automatically backed-up and archived, protecting against data loss. Simultaneously, the archived data can be called up at any time for the purposes of documentation and verification.

In a second step, the weld seam and spatter can be visualised after completing the programmed deployment of the robot torch, thanks to the simulator. In doing so, filling volumes and the position of the weld seam on the component are shown. As such, an informed decision can be made as to whether an additional cover seam is required, for example, before transferral to a real workpiece.

Virtual Welding Robotics is therefore the perfect companion to the existing Virtual Welding simulator for teaching manual gas metal arc and/or MMA welding. By recreating the real welding process, the system helps to save significant amounts of material, energy and training time.

Fronius India Private Limited, Pune. Mobile: 098206-05297. Email: sales.india@fronius.com, service.india@fronius.com

Related Products

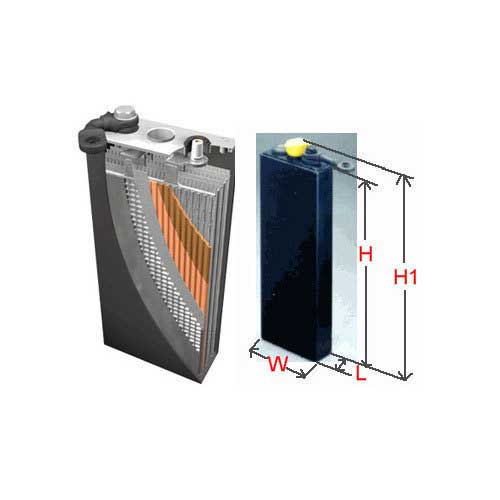

Forklift Battery

Aatous International is a manufacturer and solution provider of a wide range of forklift battery.

Impact Crusher

Laxmi En-Fab offers a wide range of impact

crusher.

Stationary Concrete Batching Plant

Nilkanth Engineering Works offers stationary concrete batching plant.