Schedule a Call Back

Taiwan International Machine Tool Show 2012

Technical Articles

Technical Articles- Dec 04,12

The Taiwan International Machine Tool Show 2012 was reflective of the machine tools and accessories industry there, reports Bhushan Mhapralkar

The Taiwan International Machine Tool Show 2012 got underway at Taichung in Taiwan between 7th and 11th November 2012. Held at the Greater Taichung International Expo Centre, the show was reflective of the capabilities and products of the machine tools and accessories manufacturers of Taiwan. Inaugurated by the Taiwan president, Mr Ma Ying-Jeou in the presence of the organisers of the show and other dignitaries, TMTS 2012 attracted 475 exhibitors from within Taiwan and from other international markets. The show, spread across three halls, measuring 36,200 sq.m, had over 2400 booths that displayed various types of high precision machine tools, components, accessories, tools, and automation equipment. While 406 exhibitors came from Taiwan, and Taichung in particular, which is where most Taiwanese machine tools and accessories manufacturers are, the show saw the participation of 21 overseas exhibitors. The overseas exhibitors came from eleven countries including Germany, Switzerland, Japan, Korea, USA, China, Singapore, Italy, Netherlands, Malaysia, and Philippines. The number of international associations and trade media exhibitors at the show was 48.

Marking a 85% increase in overall scale, and 30% increase in exhibitors over the (first) show held in 2010, TMTS 2012 drew 65,227 visitors from 45 countries including Argentina, Australia, Bangladesh, Brazil, Burkina Faso, Cameroon, China, Comoros, Congo, Cook Islands, Czech Republic, Denmark, Egypt, France, Germany, Hong Kong, Hungary, India, Indonesia, Iran, Israel, Italian, Japan, Kazakhstan, South Korea, Libya, Malaysia, Mayotte, Mexico, Mongolia, Netherlands, New Zealand, Nigeria, Pakistan, Peru, Philippines, Poland, Russia, Singapore, Spain, Sri Lanka, Thailand, Turkey, USA, UK, and Vietnam. Extending a platform where an estimated 4 billion New Taiwan dollar worth of business was conducted, reflected at the show were new trends. Trends that would change the image of Taiwanese machine tools and accessories going forward. Offering a high quality range of machine tools and accessories according to Eric Chuo, Chairman, Taiwan Machine Tool & Accessory Builders' Association (TMBA), which organised of the show, the TMTS 2012, highlighted Taiwan's growing ability to offer high quality, reliable and competitively priced machine tools and accessories. The show also highlighted an important trend where industries and technical education institutions work closely to ensure effective transfer of knowledge, and ensure the availability of highly skilled manpower.

The show, aiming at manufacturing industries like aerospace, automotive, locomotive, electrical and electronics, and more, had exhibitors that specialised in metal cutting machines, metal forming machines, tube and wire processing machines, components, parts, tools, cutters, measuring instruments, moulds, software and accessories, automation and robotics, and various associations and technical medias. Some of the participants at the TMTS 2012 were well-known Taiwanese machine tool companies like Victor, YCM, Tong-Tai, Quaser, Goodway-Awea, Kao-Ming, Far East, Chevalier, Hartford, Chmer, Seyi, and Chin Fong. If these were a few of the prominent 158 machine tool manufacturers, 292 tools and accessories manufacturers also took part in the show, among them, Hiwin, GSA, Keyarrow, Vertex, Strong, Royal Precision, Habor, Fongei and Earth Chain.

Averred Mr Chuo, speaking on the sidelines of the show, "TMTS is the biggest machine industry event in Taiwan. With precision machine tool industries located at Taichung, it was the lack of space that many exhibitors were left out." He touched upon the rapid growth of the Taiwan machine tools and accessories industry. "Taiwan has very good technological prowess and is therefore looking at offering new solutions that are more efficient and competitive. The industry is addressing the needs of different clients with different levels of products." The TMTS 2012 show, held at a time, when the machine tool and accessories industry in Taiwan is witnessing a decrease in exports to Europe due to the debt situation there, and an increase in exports to other markets of the world, highlighted the emergence of machines that are fast and furious. They also enable high-speed metal working and glass working; ensure more precision, reliability, and cost competitiveness.

Having posted a growth of 5% in the year 2012, the Taiwanese machine tool and accessories industry made it a point to display at the show, technical trends, machines that look beautiful, and address the needs of the operator. Exhibitors displayed machines that are future ready, the Precision Machinery Research Development Centre, announcing progress in the field of Taiwanese machine tool engineering design. Held at TMTS 2012 were various events and workshops concerning aesthetic design and manufacture, tooling, servo drives, tool changers, advanced manufacturing, and market trends.

If an interesting part of the show comprised visits to factories of machine tools manufacturers in and around Taichung, another interesting part was the focus on software development.

This was evident from the various software on display, new automation solutions and more. Working with various automation specialists like Fanuc, Mitsubishi, Siemens, etc., the machine tool and accessories industry in Taiwan has come to rank 4th in the world after Japan, Germany and Italy in exports. It ranks sixth in machine tool production the world over. The industry exported machines, tools, parts and accessories worth US $4 billion in 2011. With 81% of the machine tools exported accounting for metal cutting in 2011, the industry exported US $ 712 m worth of metal forming machine tools.

Interview: Picus Wu, Sales Representative, Marketing & Planning Department, Awea Mechatronic Co Ltd

How old is Awea?

Awea was founded in 1986 and public listed in 1998. It is one of the few machine tools manufacturers to be a listed company. Only eight or nine machine tools companies are listed companies. We have four factories in Taiwan, and one plant in China. We are setting up a new plant in Taiwan to make smaller machines. While Goodway is our group company, Awea makes small as well as very big machines. With 20% of the staff working in two R&D centres (one into double column type machines, and the other into VMC small machines), Awea, apart from being customer centric, is the only company that makes spindles and heads in-house. We also have a well-equipped testing lab. Each machine is tested.

What machines does Awea produce?

We make Gantry type/Bridge type 5-axes machining centres, Bridge type 5-face machining centres, Bridge type moving cross rail 5-face machining centres, Bridge type machining centres, horizontal boring mills, high-speed machining centres, and high rigidity vertical machining centres. Our new products include an extra large span gantry type machining centre and gantry type 5-axis machining centre. Awea machines are at the premium end of the market.

Does Awea have a presence in India?

We have presence in 38 countries. In India we have two dealers. Having entered the Indian market many years ago, we have sold 50 machines in India. Most of these are professional double column machining centres. In India, price is an issue. We face competition from Korea. Korean machine tools manufacturers enjoy a price advantage due to the trade agreement between the two countries.

How would you describe your company as customer centric?

We have an application development cell, which studies the needs of the customers and advises them on the most suitable solution. We also have a CNC department for software design. Our global technology centres are in China and USA.

Who are your clients?

With the Gantry type/bridge type 5-axis machining centre we cater to the exacting needs of the aerospace and automotive industry. Our clients include Toyota, Volkswagen, Ford, Mitsubishi, FAW Group, Nissan, Kobelco, JFE, Airbus, Boeing, Kennametal, ACE Micromatic, and PARI.

Interview: Lesley Lee, Overseas Department Manager, Agma

Do you have a presence in India?

We have a presence in India for more than 12 years. We sell our machines through our agents in India.

What do you manufacture?

We manufacture vertical machining centre box-ways; linear guide ways, extra high-speed linear guide ways, double column machining centres, and toggle type micro machine tools.

How many machines have you sold in India?

We have sold 11machines in India. Indian market is very price sensitive. We therefore don't find it easy to sell in India. We make reliable machines. We are honest, and do not want to make low cost machines. We don't want to compromise on quality. For our machines we use Mitsubishi and Fanuc controllers.

Interview: Dave Tsai, Chin Fong Machine Industrial Co Ltd

Do you have a presence in India?

We have a presence in India. We have two dealers in India. We find the Indian market to be very competitive. We face competition from Chinese companies.

What machines do you manufacture?

We make the most advanced press with servo motor drive. We have worm & roller drive machines. We also have knuckle joint presses. Our products assure precision. We are the only manufacturer in Taiwan to make long stroke forging press suitable for cold forging. Such presses are available only in Germany and Japan. The newest product development is the servomotor drive press.

What is your set up like? We have a factory in Taiwan and China. We operate through 80 dealers worldwide. We make up to 2400-tonne presses.

Interview: Grandle Lin, GM, Campro, Korea

What machines do you make?

What machines do you make?

We make different types of machines. We make CNC machining centres, 5-axes machines, and horizontal machining centres. We also make very good linear drives.

Do you have a presence in India?

Yes! We have a presence in India.

How do you find the Indian market?

We find India as a market with good growth. Korean companies are strong in India. We feel we need to promote our company on a larger scale in India.

How would you term yourself in comparison to the competition?

On the technological side, Taiwan's machine tools industry is stronger than Korea. We are cost competitive in general-purpose machines. We offer very good quality.

Interview: Helen Chang, Shuz Tung, Machinery Industrial Co Ltd

What products do you make?

We make pipe-bending machines. We offer CNC pipe bending and tube forming solutions.

Are you present in India? How do you find this market for growth?

We have been in the Indian market for some years now. It is a price sensitive market, and we are facing competition from companies in China, and despite the fact that we make very good quality products. While we expect that better promotion will help, the Indian market is well exposed. The buyers are well informed.

Interview: James Huang, Deputy General Manager, Marketing, Tongtai Machine & Tool Co Ltd

Do you have a presence in India? How do you find the Indian market?

We have a dealer at Delhi, in India. We have been present in India for the last twenty-twenty two years. India has the presence of many machine tools manufacturer; the market's been getting bigger. We are, in India, competing in turn key machines and customised machine tools. It is difficult to compete against the local machine tools manufacturers for standard machines. We do 60 machines per year.

What are your products like?

We make special purpose machines, tapping centres, machining centres, CNC lathes, horizontal boring and milling machines, and AI wheel machining.

Are you offering any new products at the TMTS 2012?

We are offering the HB 500 II horizontal machining centre. With this machine we are concentrating on making beautiful machines. Machines that are ergonomic, and offer the machine operator good access for change of tools, and enable him ease of operation. Machine manufacturers have been told by the Taiwan Government to make machine beautiful and more presentable in appearance. We are working on product identification.

What was the reason behind sprucing up the appearance of your machines?

We observed that the European machines are styled differently, and the Japanese machines are styled differently. We chose to adapt our styling language, and with focus on their ergonomics and ease of operation. We listened to the customers. Under the project, '2012 high-grade machine tools development plan', with counselling by the Precision Machinery Research Development Centre (PMC), we redesigned the new machine guards and achieved improvements in the aspects of machine performance and machine appearance for providing outstanding cost-performance solutions to the clients.

Any specific industry segments that you are targeting at?

We are targeting the auto industry with products tlike turning centres. We are also targeting the electronics industry.

Interview: Fran Wu, Manager, Overseas Sales, Habor Precision Industries Co Ltd

Do you have a presence in India? How do you find the Indian market?

We have agents in India. We entered the Indian market in 2006. India is a growing market. The environment in India is different from that of Taiwan. We had to modify our products accordingly, so that they can withstand the tough Indian operating conditions.

What machines do you make?

We manufacture oil coolers, water coolers, heat exchangers, ventilator filters, air dryers, and electronic controllers. We offer high quality products at reasonable prices. Competition in the Indian market stems from Japanese and local manufacturers. We have sold 50 units in India so far.

What are your plans for the Indian market?

We want to go step-by-step in the Indian market. We need to supply products that address the needs of the Indian market. I would therefore say that we have a room for improvement. To be more precise, we have been getting repeat orders from our Indian customers.

Interview: Stephie Wu, Marketing Department, Keyarrow (Taiwan) Co Ltd

Do you have a presence in India? How do you find the Indian market?

We are in India for a long time. We have few customers in India. In India we face a strong competition from domestic manufacturers. We find that the Indian companies are willing to pay more for better quality. We are eager to develop the Indian market.

We have an office in India. There is an Indian engineer who worked with us, here, for five years. Based on his drawings we can supply to India. Let me add: Indian market is changing. Buyers are willing to pay more for quality products.

What products do you manufacture?

We are the largest telescopic cover manufacturer in the world. We do 1200 telescopic covers per day. These are made at our two plants at Taiwan, and three plants in China. We have 600-650 employees. We also make chip conveyors, chip compactors and machine housings.

Any new product launch at the TMTS 2012?

Chip compactor is our new release. They crush large aluminium chips before they enter the neck part of the conveyor. We are planning to take this product to the global markets. Our chip compactor received good response from clients across the world. We are targeting machine manufacturers and end users with the chip compactor.

With the kind of products you offer, how closely do you work with machine manufacturers?

To give you an example, we developed the machine outfit for Tongtai HB 500 II. We also developed the telescopic engine cover for the machine.

Interview: Oliver Tsai, Sales & Project Manager, Royal Precision Tools Corporation

What products do you manufacture?

We make belt drive spindles, direct drive spindles, motorised spindles, and built-in spindles. Our company was founded in 2003 at Taichung, Taiwan. We are dedicated to making high precision machine tool spindles. 45% of products we make go to the domestic market. Another 45% go to the China market. The remaining find their way to the other markets, prominently the European markets.

Do you have a presence in India?

We have a few customers in India. We also have a few smaller buyers there. We do 2000 spindles per month. In India, we supply to Jyoti CNC Machines. Price is an issue in India. We negotiated for half a year with our first customer. Customers in India have come to appreciate our products, and we are getting repeat orders. We are very keen to increase our sales in India. We want to gather more presence in India.

Do you have a dealer in India?

We have found out that Indian customers do not like agents; they contact us directly. As far as competition goes, China is not a big competitor in spindles. Our competitors come from Europe. European spindles are of a very high quality. The companies, which make them, have a long history; they also have technology. We are ten years behind them.

Are you presenting any new products at TMTS 2012?

We are presenting a high technology, high-speed spindle at the show.

Interview: Lucas Chang, Manager, Overseas Sales Dept., Sun Yuan Technology Inc

Are you present in India?

We entered the Indian market a year and a half ago. We have clients in India like ACE and Bisse. India, for us, is a booming market. There are people looking for overseas suppliers. For us, India is a priority market. Clients from India are more aggressive.

What is your market spread?

70% of our sales come from Taiwan. South East Asia accounts for 15%, and the other markets account for the rest of the sales.

What products does your company manufacture?

We manufacture machine bellow covers and wipers. In India, we have sold 200 pieces of these two products from the time we entered. While I would want to stress that buyers in India are keen on low cost products, our focus on the Indian market includes competition from Europe. We will thus be aggressively competing with the European manufacturers. We may also set up a factory in India at a later stage. We were founded in 1989, and have two plants; one at Taichung and the other at Taipei. Our third plant is near Taichung is coming up.

With the third plant coming up, what are your plans for the future?

We are creating more opportunities as far as our global thrust is concerned. We are looking for new partners for Japan, India, and a few other markets. We are also keen to enter markets like Russia. The TMTS 2012 show makes an important show for us as it helps to extend the Taiwan machine tools and accessories industry.

What new products are you showing at TMTS 2012?

We are focusing on new material and higher speed. We are focusing on horizontal, higher speed modular system. These have been newly developed, and are finding application with Japanese manufacturers.

What kind of growth are you looking at from the Indian market?

We are looking at 0.1 billion New Taiwan Dollars business from India.

Interview: Mr Kennedy Lin, Sales, Jiuh-Yeh Precision Machinery (Millstar)

Do you have a presence in India?

We have dealers in India at Bangalore and Mumbai. We have sold 30 to 40 machines in the Indian market.

What machines do you make?

We make vertical and horizontal machining centres. Knee type milling machines, bed type vertical and horizontal milling machines, bed type vertical milling machines, and bed type turret vertical milling machines. We also make traditional machines.

How do you find the Indian market?

India is a very good market.

Related Products

Linear Motion Solutions

Delta Electronics India Private Limited offers a wide range of linear motion solutions

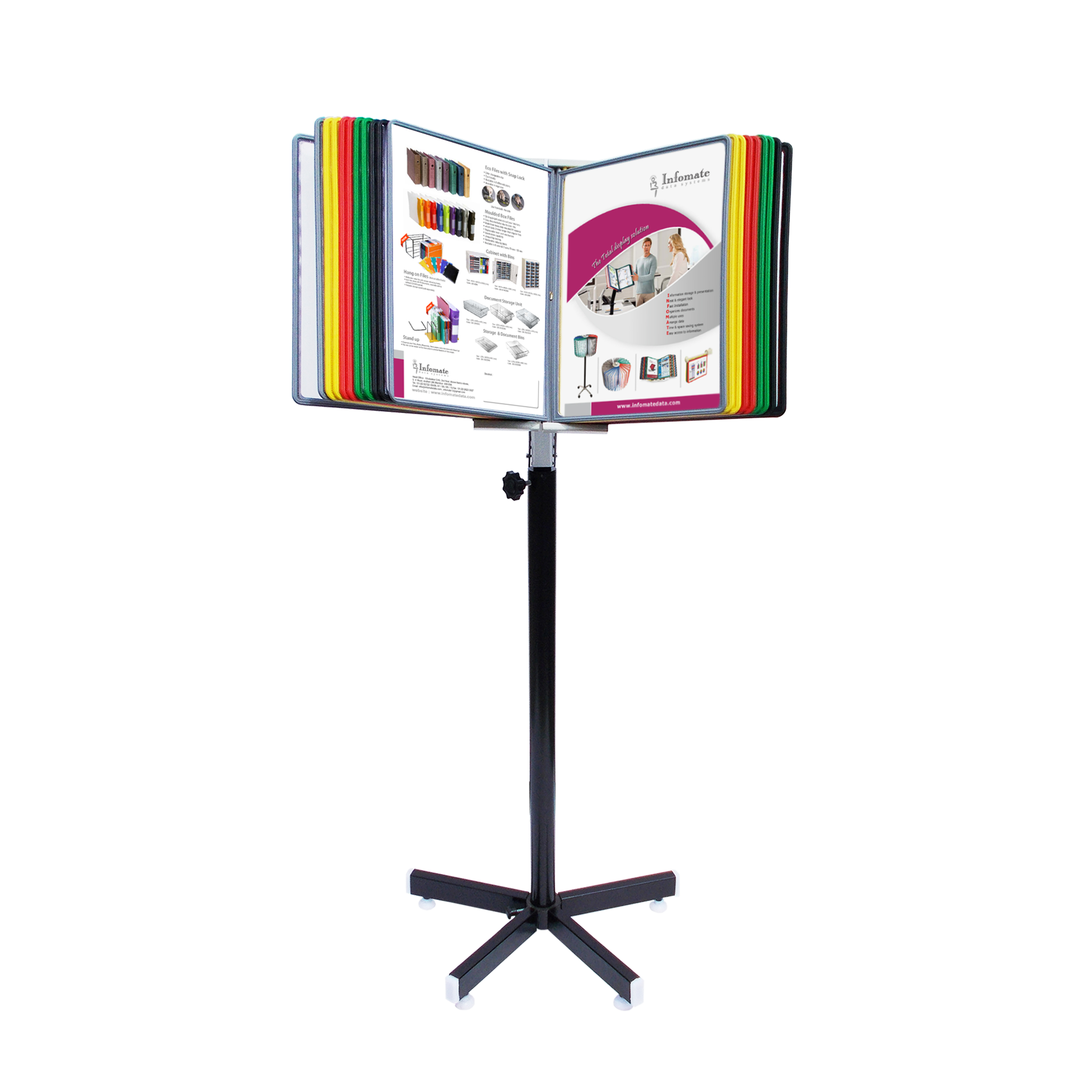

Total Display Solution

Roto

Leaner Technology Pvt Ltd offers a wide range of total display solution.

Uv, Fiber, Co2 Laser Processing Systems

C And C Laser Engineering Pvt. Ltd. provides flexible, cost effective and low maintenance CO2, IR – Fiber/Diode-pumped, GR & UV marking & other pro Read more