Schedule a Call Back

Strip-Coil Joining Weld Equipment

Technical Articles

Technical Articles- Mar 07,13

Kriton Weld Equipments Pvt Ltd offers a range of Strip-Coil Joining Weld Equipment

In steel plants and other metal strip processing industries, the coil after the coil welding is important to continue the process which involves lot other functions to prepare the end product. Mainly ferrous and non-ferrous strips manufacturing needs a suitable welder to ensure continuous process in limited available time.

Overlap Resistance Welding is very useful for this type of applications. Mainly steel-strip processing industries have wide applications for such welders. Some of the arc welding and combination of resistance and arc welding (mainly MIG) are employed in such cases. Much depends upon the thickness and width of the strips. For higher thickness, laser welding is also sometimes suggested but it is quiet costly and requires the economic study of end products.

If we discuss the application in steel processing lines, the exit coil is welded to entry (new) coil by resistance seam welding process. This process requires the lap-joint at the weld region. Mainly coil seam welders are available with the following basic characteristics:

- Wide overlap seam welders, minimum overlap seam welders

- Mash seam welders, mash and arc combination seam welders, and

- Shear-arc welders, etc., -- all with auto-sequence of operations through PLC. Following Steel Processing Lines generally use welders for the process:

Continuous galavanising, coil built-up, coil preparation, chrome plating, cleaning, decarburizing, electrolytic tinning, inspection line, side trim and recoiling, slitting, terne coating, tension levelling, annealing and pickling, shotblasting and slitting, etc. The materials that can be welded are:

Continuous galavanising, coil built-up, coil preparation, chrome plating, cleaning, decarburizing, electrolytic tinning, inspection line, side trim and recoiling, slitting, terne coating, tension levelling, annealing and pickling, shotblasting and slitting, etc. The materials that can be welded are:- Uncoated low carbon steels, med. carbon (less than .5% carbon) steels, ferritic stainless steels, steels with coat of tin, paint chrome, aluminium and lead coated, silicon steels, and non-ferrous materials. The allied equipment that can be part of whole weld plant along with a coil steel welder are:

- Shearing and sheet indexing, strip notcher, hole punch, side guides, looper rollers, sheet centring units, microprocessor weld controls (programmable), welder PLC with suitability to connect to plant PLC, water chillers, etc.

(Contact: Kriton Weld Equipments Pvt Ltd, Vadodara. Tel:0265-2642809, 2645070, 2651718. Fax: 91-265-2638761. Email: info@kritonwelders.com)

Related Products

Infrared Thermometer

Nunes Instruments offers a wide range of infrared

thermometer.

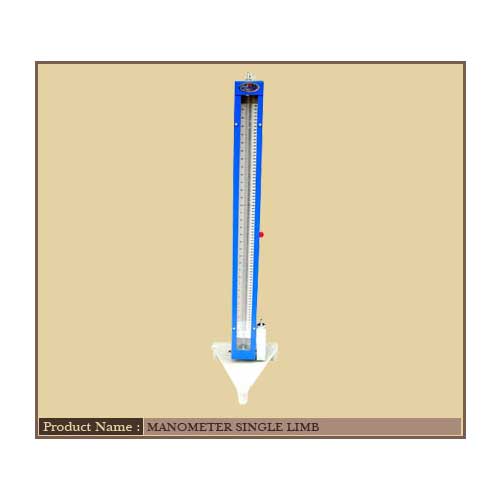

Manometer Single Limb

Zoom Instruments Manufacturing Company

manufacturers manometer single limb.

Cp 116 - Atmospheric Pressure Sensor

Kimo Electronic Pvt Ltd offers a wide range of CP

116- atmospheric pressure sensor.