Schedule a Call Back

Secure Solution for New Tube Forming Geometries

Technical Articles

Technical Articles- Aug 08,13

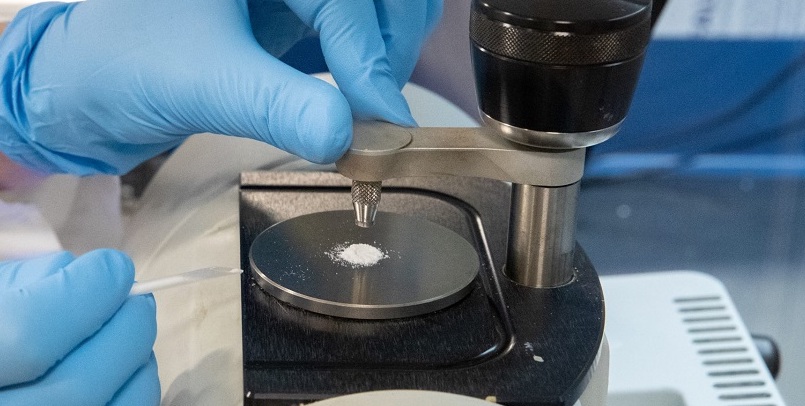

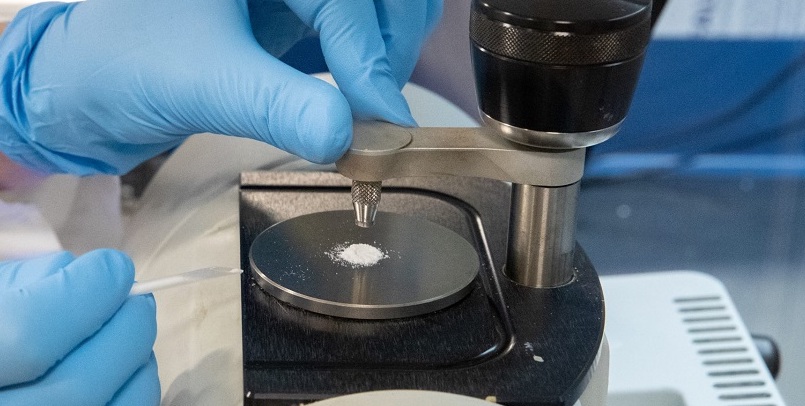

Surprises are often seen as pleasant things, but those of a more irritating nature should naturally be avoided right from the beginning of the development of a new product onwards. That this is in particular a real challenge in the area of tube forming technology, is of course due to ever more complex requirements and smaller tolerances. The prototyping department of Transfluid takes care of this. In the research department, components and tools up to 45 mm pipe diameter can also now be tested. Versatile testing is carried out on two axial forming machines, which dispose of up to 25 tonnes of forming force, and on a CNC-operated rotary forming machine.

Precise Testing up to Series Maturity

We don't just deal with sampling of new developments for our own use. Highly precise forming tools are naturally also employed in concrete customer projects. On request, the special department will test new forming geometries and efficient future tool concepts for their quality up to series maturity. Modern means of measurement, like for example, a measuring station which operates both optically and tactilely, ensure that components and tools are exactly measured and the results can be reliably documented.

Testing Pilot Series Without Large Machinery

Transfluid has created the opportunity for clients to exactly investigate and precisely improve a pilot series without their own large machinery. The assessment can be carried out with high-strength materials and light construction components and, according to geometry, even independent of tools. Thus, the company offers pilot series or prototype production at minimum cost. transfluid is sought after world wide as a partner in the production of tube bending machines and tube processing machines. Since 1988, transfluid has been further developing its technologies for tube processing in a customer orientated way and thus offers tailor-made solutions - for plant and mechanical engineering, the car and energy industry, ship-building right up to the production of medical equipment. At the EMO (Machine Tool World Exposition) in Hannover, from the 16th to the 21st of September, this prototyping will also be a topic of transfluid. The company will be situated in hall 4, stand G25.

Related Products

High Speed Tripping Relay Two Element Relay - Jrv 181x2

JVS Electronics Pvt Ltd offers a wide range of high speed Read more

Plenty of Motion Possibilities in a Compact Housing

B&R Industrial Automation offers a wide range of plen Read more

High Speeed Tripping Relay Three Element Relay

JVS Electronics Pvt Ltd offers a wide range of high speed tripping relay three element relay - JRV 181x3.