Schedule a Call Back

Salvagnini Open House Review: Choosing the right size

Technical Articles

Technical Articles- Oct 13,15

In mid-July 2015, Salvagnini Maschinenbau, the largest panel bender production plant in the world, conducted an Open House in Ennsdorf, Austria, presenting visitors a superb opportunity to experience a comprehensive display of machines that has made the company the undisputed market leader with 3000 panel benders installed all over the world. Many discerning users consider the company a state-of-the-art source for sheet metal machines in general, and for panel bending systems in particular.

A history of successes that, focussed on just “panel bending”, started in 1977 with the presentation of the first prototype and continues over the years down to the present days, when Salvagnini has become the authoritative spokesperson for so-called “Panel bending 4.0”: a flexible process, as never before, with application boundaries that have also been extended to those sectors and fields considered unsuitable for panel benders since time immemorial.

The Salvagnini 4.0 modern panel bender is a machine designed to combine advanced technology and ease of use, capable of guaranteeing bending results that are optimal from the very first part and, above all, constantly repeatable over time thanks to total control of variables during the whole process.

The Salvagnini Austrian factory is in fact dedicated to the development, optimisation, production and fine-tuning of everything orbiting the panel bending world. It is currently the largest global centre of competence for panel bending as well as the largest panel bender production factory in the world. Not just a production site, but a real centre of competence where customers, through the numerous solutions exhibited, were able to touch at first-hand all the potential of technology that Salvagnini is enriching and developing all the time.

The process solutions on show

During the Open House, a visitor were treated to various solutions that bear witness to the company’s ability to contextualise and integrate the widest range of panel benders available on the market into the customer’s business and production methods. There was a range of models: from the standalone P1 and P2lean panel benders to the more complex ones, integrated with various different levels of automation.

The P1 is a compact panel bender in the Salvagnini range: an entry-level machine, of limited dimensions and very low power consumption. Thanks to its innovative patented bending kinematics, the P1 has extended the field of application of the panel bender to productions that had until now been unachievable.

Because of its high productivity (up to 2 seconds per bend), extreme repeatability precision and cost-effectiveness, the P1 represents the ideal solution for the production of any type of panel, with either a simple profile or elaborate bends, and is a valid alternative to traditional bending.

P2lean is the flexible bending solution with which Salvagnini has rewritten state-of-the-art panel bending. New application possibilities and reliable part quality are two arguments that make this new panel bender model a machine suitable for any type of customer, “subcontractors” included. However, the P2lean combines application versatility with unmatched bending quality in terms of processing precision, repeatability and appearance and – this is no mean achievement – low power consumption.

The same innovative concepts of the P2lean have been exported for the first time to the panel benders in the P4 series: two different configurations of P4lean-2116 were previewed as further evidence of the capacity to shape the same machine model according to the production context, in order to respond to different production requirements.

One model for three different solutions

The P4Xe-2516 panel bender was the other great star at the Open House because it presented three solutions and configurations that satisfy precise production constraints. Two P4Xe-2516 panel benders integrated into a High Speed Line (HSL) cell with the Salvagnini two-head S2 punching machine upstream, with suitably configured and optimised production cycles, can produce, in a combined arrangement, elevator doors with times and performances similar to those of a high-production line. In fact, every 15 seconds, this solution can produce the metal components needed to make a door in full compliance with the specifications of a customer who, in this case, required the performance typical of a high productivity line but without the rigidity and inflexibility associated with this type of solution. Just a little further on, the HPT+P4Xe-2516 high thickness solution displayed a “basic” version of the same P4Xe panel bender equipped to process metal sheets with thicknesses exceeding 3 mm.

The MVP+RIP+P4Xe-2516.P.CUT, on the other hand, displayed another solution based on the P4Xe-2516 panel bender but in a super automated version, fitted with a single-sheet store-tower with six levels that allow parts to be produced from six materials that are all different in terms of thickness, shape and composition. By setting up the six levels appropriately, it is therefore possible to fulfil an order by launching the production of all the parts making up, for instance, a metal cabinet, even if this involves different materials.

So many solutions for large formats!

With the P4Xe-3216 and P4Xe-3816 panel benders, visitors were able to experience first-hand how Salvagnini manages to guarantee the same level of performance in terms of flexibility, precision and quality with large sizes too.

The P4Xe-3216 is, in fact, an increasingly attractive machine to subcontractors too, because of the possibility of processing panels from less than 300 to more than 3,000 mm, guaranteeing the same processing flexibility and performance as a smaller panel bender. The P4Xe-3816 is the XL solution similar to the previous one but even more dedicated to those sectors that need to make very long parts (almost 4 m) in just one step.

The S4Xe+P4Xe is, finally, one of the most successful Salvagnini solutions, punching, shearing and bending sheets without any interruption in the process from sheet to finished product, and without any intermediate handling of the semi-finished parts. The S4Xe+P4Xe line has always represented a milestone in the development of solutions for integrated logistics and is still the most efficient flexible sheet metal processing system (FMS) on the market.

The panel bender comes back to life

As the final stop at the Open House, visitors also had the opportunity to test a new Salvagnini product line: reconditioned panel systems. Re-NewS is the name of this new range of “renewed” machines that Salvagnini accepts back and updates to the current state-of-the-art in order to recreate an advanced and guaranteed technological product, and that allows customers to enjoy the features of Salvagnini systems at a more attractive price than the new version. Re-NewS systems are retrofitted by the original manufacturer and brought back to optimal running condition. Updated both mechanically and electronically in order to enhance reliability and spare part availability, they meet the quality, safety and performance criteria that characterize all Salvagnini systems.

Related Stories

Statiq and BMW Partner to Build High-Speed EV Corridors

This collaboration, BMW Group India and Statiq have established a robust charging corridor covering over 4,000 kilometers from Jammu to Madurai.

Read more

How Indian manufacturers can thrive in the volatile global supply chain era

In this article, Dijam Panigrahi, Co-founder and COO, GridRaster Inc, explores how manufacturers can build resilient, agile supply chains by leveraging technology, investing in people, and forming s..

Read more

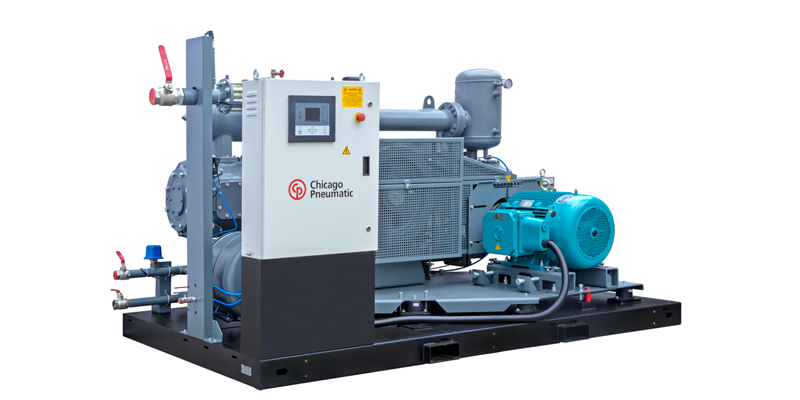

Top eight maintenance tips to extend the lifespan of reciprocating compressors

In this article, Siddhartha Guin, Business Line Manager (CTS), Chicago Pneumatic Compressors, India, shares essential maintenance practices to help extend the lifespan of these vital machines. From ..

Read moreRelated Products

Single Pole, Neutral Displacement Relay

JVS Electronics

Pvt Ltd offers a wide range of single pole, neutral displacement relay -

JRV 962.

Face Mill Arbors

Schunk Intec India Pvt Ltd offers a wide range of face

mill arbors.

Hardy - Chassis Mounted Weighing Card for Rockwell PLCs

Kore Mechatronics Private Limited offers a wide range of

hardy - chassis mounted weighing card for Rockwell PLCs.