Schedule a Call Back

Reconditioning of Machine Tool Guideways

Technical Articles

Technical Articles- Mar 12,15

Rollon Bearings Pvt Ltd presents a Technical Paper on Reconditioning of Machine Tool Guideways by using Rollon Slideway Material

Rollon Slideway surface linear bearing material is the proven linear bearing material used globally by OEMs and reconditioners for machine tool guideways, jibs, wedges, rotary tables or any linear movement application to check metal to metal contact, where reduced friction and wear resistance are critical design considerations. Studies of the various bearing load and speed requirements in a variety of industries were made. Comparisons were made of lubrication requirements and wearing characteristics of conventional bearing materials and possible combinations of the fluorocarbon plastics. The results of this research and an extensive market survey led to Rollon Slideway, a bearing material, which offers many savings in operational costs. With Rollon slideway, equipment has no down time for lubrication and parts replacement due to inadequate lubrication. No grease fittings are required. Run-in time and starting power are reduced appreciably. Accessibility for lubrication no longer poses a problem. Waste is eliminated in industries where oil contamination must be avoided.

The following brief notes contain complete physical data and design information for specific bearing needs.

Application of Rollon Slideway- Accurate positioning

- Minimum requirements of lubrication

- Galling is avoided

- Traditional machining methods

- Minimum wear and long service life

- Low and constant friction, and

- Vibration damping.

- Reconditioning with Rollon Slideway

Rollon Slideway is actively used for the reconditioning of machine tool guideways, jibs, wedges, Rotary tables, etc. The advantages of reconditioning with Rollon Slideway go beyond obtaining improved working properties. The original centres can be maintained unchanged and the necessity for bedding in is eliminated.

Salient Features & Advantages- Eliminates stick-slip

- Prevents wear

- Ensures fast

- Smooth chatter free travel

- Renews worn equipment

- Reduced high breakaway friction

- Holds position

- Installs easily

- Self-lubricating

- Tough & durable

- Wear resistant, and

- Controlled low friction.

Why do machine tools need Rollon Slideway linear bearing system?

Why do machine tools need Rollon Slideway linear bearing system?The friction and wear of machine tools sliding members has a significant effect on the accuracy and service life of the tool. Both insufficient and excessive friction will prevent accurate positioning. Excessive friction also causes wear that makes accuracy and repeatability unpredictable.

Rollon Slideway Material

Rollon Slideway keeps friction at optimum performance levels and makes wear negligible on both sliding surfaces. Rollon Slideway also causes friction to remain more constant under varying workloads and feed rates than with flat or V ways riding on full contact oil film. Sliding members fitted with Slideway linear bearings have a smooth, steady feel, free of vibration and stick-slip even without lubrication.

Rollon Slideway linear bearings will significantly improve accuracy, productivity and maintenance free service life of NC machine tools, special purpose tools and all machine tools that depend on sliding members to position the work pieces or tools. Light and heavy tools can be positioned rapidly without the need for ball bushings or roller bearings. And because stick slip is eliminated by Rollon Slideway, elaborate and expensive lubrication systems are unnecessary.

How does a Rollon Slideway linear bearing system work?

The application of a Slideway Linear bearing system is a simple procedure easily adaptable to the requirements of the original equipment manufacturers, the tool rebuilder or the maintenance machinist.

One of the bearing surfaces of the tool is first prepared with any industrial degreaser non-oil based like Acetone, Trichloroethylene, etc., to assure that it is free of bond inhibiting contamination. Then Rollon Slideway material is bonded to the bearing surface with Araldite. Usually, the Slideway bearing moves with the work table or tool holder along with steel or cast iron mating surface of the tool way, but it can be bonded to the tool way. The static and dynamic friction of Rollon Slideway is nearly the same on both cast iron and hardened or soft steel ways.

The self-lubrication properties of Rollon Slideway protect the ways from damage when the lubrication system fails or when periodic lubrication is neglected.

Plus, in 40 years of service tests, the Slideway bearing system has been proven superior to other types of linear bearing systems. Both new and rebuilt machine tools using Rollon Slideway bearings have demonstrated a significant competitive edge over machine tools fitted with conventional and friction surfaces such as Ball Bushings, Roller Bearings and V or flat ways that depend on oil film to reduce friction.

Design Information

Friction: The static and dynamic coefficient of friction of Rollon Slideway bearings falls between 0.03? to 0.3?. Meaningful variations of the friction coefficient within this range depend primarily upon unit loading, velocity, lubrication and run-in. Some differences in the friction coefficient may occur between soft and hard ways, steel and cast iron ways or ground and scraped ways, however the effect if these variables on friction is minor.

Wear: Lubrication and surface finish are the principal factors affecting the wear life on ground or scraped steel and cast iron ways. The self-lubrication qualities of Rollon slideway prevent excessive wear, even if lubrication fails. Wear of both dry and lubricated installations fall well within the required limits for even the most precision machine tools. Correct surface finishes ensure optimum wear.

Load Capacity: Rollon Slideway linear bearings perform best under a load of between 50 and 800 PSI. Depending upon the allowable creep and service temperature, Slideway bearings may be used up to 1600 PSI.

In most design configurations, Rollon Slideway linear bearings provide a load capacity far greater than the "work piece load" capacity offered by the machine size. For example, a small machine tool table two feet in length with approximately ?" ways would have a total Rollon Slideway bearing area of 24 square inches or a load capacity of 38,400 lbs.

Advantages of the Rollon Slideway Linear bearing system to manually operated machinery

Designing for new equipment

The Rollon Slideway linear bearing system is finding wide acceptance in non-numerical controlled machine applications. The unique advantages in the areas of constant friction, long wear life, design simplicity, smoothness of operation, uniform wear, low maintenance and ease of retrofit have proven to be important to engineering requirements. Some examples are as follows.

The Importance of Rollon Slideway to Machine Rebuilders

Most machine rebuilders use Rollon Slideway linear bearings onto carriage cross slides, carriage hold downs, compounds, adjustable gibs and taper attachments. Costly hand scraping of the ways becomes unnecessary - ways need only be planed or surface ground flat and parallel. Rollon Slideway linear bearings are applied to lathes having either cast iron, soft or hardened steel ways. The resulting performance advantages are the carriage moves smoothly both on automatic and hand feed, there is no tendency to stick-slip during hand operation and Rollon slideway linear bearings exhibit vibration dampening characteristics resulting in improved machined finishes on the work place. In many instances, the finishes and tolerances obtained are superior to those, which were obtainable when the machine was new.

Advantages of the Rollon Slideway linear bearing system to numerical controlled machinery

Numerical control systems convert electrical signals to linear table travel and positioning through the use of DC motor driving, either a ball screw or a hydraulic drive system. The DC motor drives two feedback devices: one for velocity control and the other for positioning control. The positioning control generates 10,000 signals for each inch of travel; each of these signals represents a potential stopping point.

A complete drive system as described above is duplicated on both the X and Y axes. Considering that the table must be able to be stopped and held at any particular, predetermined one-ten thousands of an inch, the following bearing characteristics of Rollon slideway are important:

Some friction for holding and minimizing over travel

- Low differential static versus dynamic friction to prevent stick-slip, and

- Low breakaway friction to minimize the signal voltage gain when restarting the table excursion.

Typical of the importance of friction are its effects during high differential X-Y motion.

Example: When cutting a circle, one axis must decelerate to zero while the other axis accelerates to a maximum pre-set feed rate. Correspondingly, the actual tool cutting forces will vary in the same relationship. The engineered friction characteristics of the Rollon Slideway linear bearing system ensures smooth translation from X to Y, eliminating over-voltage and consequent over-reaction of servo-motors.

Availability

Rollon Slideway is available in thicknesses of 0.8, 1.2, 1.6, 2.0, 2.5, 3.2 and 4.0 mm thick x 12" width x length to suit users' requirement

(The company has a ready stock of genuine material and a technical team for any technical support. It has vast experience in this field and can support in selection of the right linear bearing material and thickness of Rollon Slideway for specific applications.)

Rollon Bearings Pvt Ltd, Bangalore. Tel: 080-22266928, 22250287. Fax: 91-80-22250319. Email; rollon@rollonbearings.com

Related Products

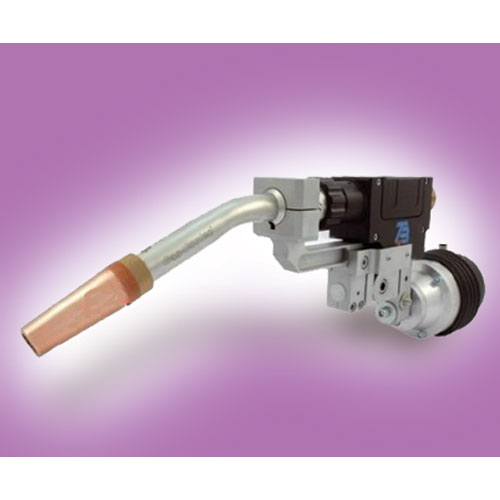

Welding Automation

Drupe Engineering Private Limited is offering a wide range of welding automation.

Robo Mig Tbi Robot Welding Torches

Mehta Sanghvi

& Company manufactures Robo MIG TBI robot welding torches.

Heavy Duty Goliath Crane

Ganesh Engineering Co manufactures and supplies a broad array of heavy-duty goliath crane.