Schedule a Call Back

Order Today, Get it Tomorrow'

Technical Articles

Technical Articles- Apr 02,14

Baumer India, manufacturer of sensors, encoders, measuring instruments and image-processing systems, has created a niche for itself ever since it started its operations here in 2007. Now, there is a grand plan to scale up its activities with a new production facility at Pune and total indigenisation of its components. In this interview, Dr Oliver Vietze, CEO and Chairman, Baumer Group elaborates about this expansion plan.

Could you elaborate about Baumer Group's worldwide operations?

Headquartered in Frauenfeld close to Zurich, Switzerland, the Baumer Group is an international leading manufacturer and developer of sensors, encoders, measuring instruments and components for automated image-processing as well as systems for adhesive application and quality control. The company combines innovative technology and customer-oriented service into intelligent solutions for factory and process automation and offers a uniquely wide range of related products and technologies. Now with around 2,300 employees and 37 subsidiaries spread across 19 countries, the company was found in 1952 by Baumer Herbert and was taken over by Helmut Vietze after Herbert died in a car accident in 1964. Our last year's turnover was about Euro 300 million.

What about India operations?

Baumer India Private Limited has been present here since 2007 with a production facility at Vapi. The company has till date invested USD 25 million in Indian operations. Baumer India has a strong position in the segments of gluing systems and motion control. In the sensor solutions' business we are recognised as a quality supplier of premium products and have a market leadership as supplier of heavy-duty encoders to core segments like steel, mining, packaging, pharmaceuticals, wind energy, material handling and cranes. Baumer Huebner is also known as a reference brand in all these sectors. In gluing systems and quality assurance systems for packaging, Baumer is virtually an industry reference standard with the largest number of installations in the country.

Our sensor solution business is one of the fastest growing with very innovative products introduced in the Indian market. This segment is continuing to grow at 50 per cent per annum basis even under relative slow economic growth this year. Baumer's vision technology products such as smart vision sensors and industrial cameras find wide-ranging applications in diverse industry segments such as food, automotive, engineering and robotics.

This is really the frontier of technology in terms of automatic inspection systems using smart vision sensors and cameras. The Indian market for high-technology products that Baumer offers is close to Rs 400 crore and we command a 15 per cent market share in India.

So are you scaling up your production output in India?

There is a long-term plan on the anvil and to begin with we have expanded our sales and sourcing activities in Pune with a new office at Warje. This is not only because it will help us to be closer to our customers but also to fulfill the objective of sourcing local components from India. The company has started an engineering, training and assembly center at Pune which will not only act as a demo centre for our customers but also provide training inputs in how to use our solutions. The bigger plan is to set up a factory in Pune to manufacture electronic pressure sensors.

This will entail an investment of USD 10 million dollars over the next two years and increase the headcount from 30 to more than 100 people. Our next step at Pune after electronic pressure sensors would be to manufacture encoders and sensors and the production will also be used for exports at a later stage. All this should hopefully become a reality over the next six months. Our Vapi plant will continue to make products for process instrumentation, 20 per cent of which are exported to countries like the US, Latin America, China, Africa and the Middle East.

Does the plan include increasing indigenisation?

Yes, because we believe that efficient sales and servicing can happen only when you are able to achieve very quick turnaround time in delivery. This implies that there should be no long waiting periods for components or finished products. Order today, get it tomorrow. That should be the ideal situation. The local engineering team will also help Baumer factories worldwide develop and source quality components from India. Our expansion plans are based on making the best use of local talent available. In each of the countries it operates, the company strongly believes in local management. Thus, the Indian unit is an integral part of Baumer Group's strategy to build products catering to high-technology requirements at a sustainable price. We are already in the process of identifying local vendors. The idea is to attract the best quality components so that the products manufactured in India will also pass the test for global acceptance.

Has there been any recent product development for worldwide applications?

To give you an example, the Baumer Group has further optimized their IFBR inductive sensors for hygienic applications. The sensor front caps are provided with a new special plastic that conforms to strict EU regulations. In particular, EU regulation 1282/2011 places high demands on plastics that come in contact with food. The new IFBR makes Baumer one of the few worldwide suppliers in the inductive sensor field that complies with these strict regulations. The new sensor front cap is also extremely resistant to corrosion or abrasion.

During the development Baumer used all the experience gathered over so many years and its broad portfolio for the hygienic design sector, especially in food and beverage. The wash-down design ensures that the sensors withstand the frequently necessary for intensive cleaning and disinfection cycles.

ProTect + gives the IFBR series a unique Baumer sealing concept that goes beyond the requirements of IP69K and guarantees maximum isolation, even after many temperature cycles. In addition to the sensors, the associated HI mounting accessories comply with the regulations for hygienic applications. Even the mechanical mountings are subject to the same strict requirements as the sensors.

To give you another example, we have expanded our portfolio of NextGen sensors to include the new series U500 ultrasonic sensor. With the same design, dimensions and application concept as the series O500 photoelectric counterpart, the U500 sensor by Baumer provides even more flexibility as early as during the system planning stage. The ultrasonic sensor offers several advantages over photoelectric sensors.

The measuring principle makes it possible to detect transparent, high-gloss and multicoloured objects - in solid and liquid form. With a sensing distance of up to 1,000 mm, the U500 also offers the greatest range in its class, while also being dust and dirt-resistant. A further advantage is the narrow, symmetrical sonic beam angle, with a diameter of only 80 mm at an object distance of 500 mm. This allows the U500 to be used in applications with very cramped spaces.

(Contact: Baumer India (P) Ltd, Pune. Tel: 020-66292400. Email: shasabnis@baumer.com)

Related Products

Fieldpower Power Bus System

Weidmueller Electronics India offers FieldPower power bus system.

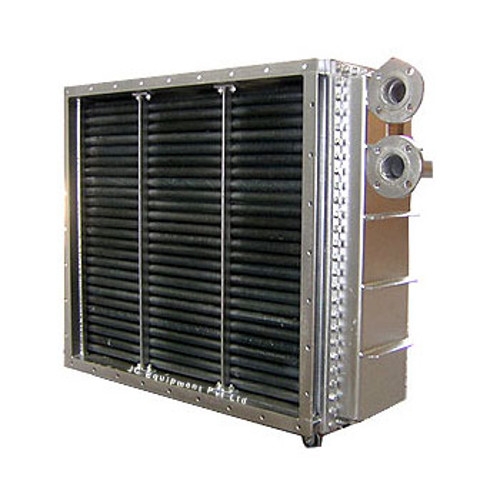

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Ceramic Reinforced Grinding Wheels

Rüggeberg GmbH & Co KG,

PFERD-Werkzeuge, has launched new reinforced grinding wheels with ceramic oxide

grain.