Schedule a Call Back

Oerlikon's Drive Systems inaugurates Sanand Plant

Technical Articles

Technical Articles- May 15,15

Oerlikon, the globally leading Swiss company active in the fields of surface solutions, manmade fibres, drive systems and vacuum generation, has been present in India since the mid-1980s, across all the four segments.

Oerlikon's Drive Systems Segment inaugurated its third plant at Sanand in Gujarat, which happens to be the 10th production facility for the segment globally. "This inauguration marks an important milestone for the further development of Drive Systems Segment in India. With the additional production capacity, we continue our growth in India and further upgrade our capabilities in high-tech driven products," said Dr Bernd Matthes, CEO of Oerlikon's Drive Systems Segment. The plant is presently assembling CVT transmissions for agricultural tractors (for export to Case New Holland, Mexico) transaxles for leisure vehicles (Club Class golf carts for USA), and PRT-10 axles for wheeled loader and other on/off-road applications (JCB, India).

The company's Drive Systems Segment has been present in India since 1999, with production sites of both its brands Oerlikon Graziano and Oerlikon Fairfield at Greater Noida and Belgaum respectively. With the region acquiring increasing significance for Oerlikon, both as a market and as a manufacturing base, this production site will further boost the ambition of the company to be a trusted partner for OEMs in emerging markets as it already is in developed markets. "In less than two years after the ground breaking ceremony, we have commenced production at Sanand. With this new capacity we will continue our journey in India and upgrade our capabilities in high-tech driven products strongly supporting our customers in developing new innovative solutions for the domestic as well as international markets," said Dr Bernd Matthes.

This is the first phase of the Sanand plant, built at a cost of Rs 120 crore and employs a total of 125 personnel. The construction of second phase begins shortly, in what will ultimately be a six phase project built at an estimated cost of Rs 1000 crore. The quality of the production and facilities - testing, paint shops, etc., is the same as it is globally, across other Oerlikon facilities.

Oerlikon's Drive Systems Segment has grown from strength to strength in India over the last decade and a half. Today it serves domestic as well as export markets, covering not only the Agricultural market, but also Construction Equipment, Commercial and Utility vehicles as well as industrial applications. The new plant is spread across 35 acres, and will employ more than 1000 people when in full production. The plant is testimony to Oerlikon's commitment to being a responsible corporate citizen. "More than a third of the site has been planned to be 'green'. We have an energy efficient building resulting in 30% reduction in energy requirements, plus zero discharge of water and 100% rain water harvesting and waste water management. We have built the plant to comply with LEED Gold Standard criteria and will be applying for certification shortly. We aspire to be sustainable in all aspects and emerge as the trendsetter amongst our peers in the region," said Vivek Prakash, Business Unit Head, India at Oerlikon's Drive Systems Segment.

"Sanand is an established hub for automobile companies and is a key area for good engineers specialising in assembling products and prototyping. The new plant would not only give proximity to the port but will also enable Oerlikon's Drive Systems Segment to make high-tech products and solutions at competitive costs by leveraging India's strength, as best cost labour market, and with numerous of our existing and potential customers being in the region it will give Oerlikon an added advantage of being close to them," he added.

The next phase of construction of the Sanand plant will commence soon given the above distinct advantages. While the plant in Noida is more specialized in manufacturing high-precision gears and synchronizers under the Oerlikon Graziano brand, the Belgaum plant focuses on assembly drive units for industrial applications under the Oerlikon Fairfield brand. At the Sanand plant, the range of products will be from transmission synchronizers, for which India is already recognized as an international competence centre, to assemblies for full and final transmissions as CVT transmission for agricultural tractors, transaxles for leisure vehicles, and axles for wheeled loader and other on/off-road applications. While large castings for the present production at Sanand are sourced from Europe, smaller castings and gears are from Oerlikon's Noida plant and local vendors. The company has one of the best gear manufacturing plants in the country. It will be looking at creating a vendor based in Gujarat.

Oerlikon in India is a single source supplier of synchronisers to major OEMs such as VECV, Tata Motors, and Force Motors and wheel loader axles to JCB, Hitachi and L&T in the construction equipment segment.

Related Products

Fault Annunciator

Insys Electrical & Controls offers a wide range of fault annunciator.

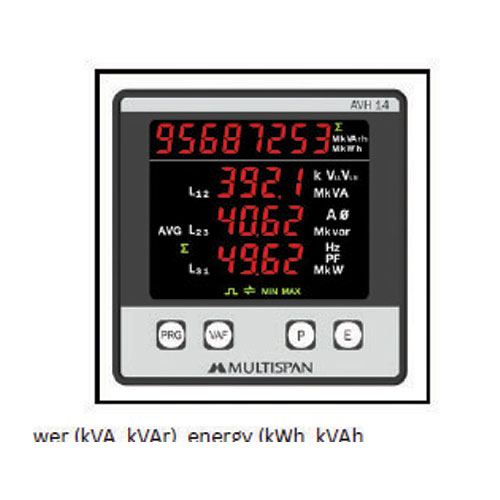

Multifunction Meter

Insys Electrical & Controls offers a wide range of multifunction meter.

Safcon Bolt Container Seals High Security Seal for Containers & Cargo

Safcon Seals Private Limted offers a wide range of safcon bolt container seals high security seal for containers & cargo.