Schedule a Call Back

Nailing it Right

Technical Articles

Technical Articles- Jul 01,11

Nagpur-based Univenture Corporation's tie-up with Danish company Enkotec has resulted in the setting up of a unique wire nail making machine capable of producing 1,000 nails per minute, reports Huned Contractor

As the summer heat soared in Nagpur, Maharashtra, and the month of March marked the closure of financial year 2010-11, some hectic activity was witnessed on the premises of Univenture Corporation. This was because of the fact that India's first and fastest wire nail making machine was to be inaugurated as also for the creation of an important industry milestone through the first Indo-Danish joint venture in the city.

The machine, called MI01, works on a unique rotary head forming principle, which is what makes it stand apart from the other machines in the world. The MI01 is capable of producing 1,000 nails per minute, over five times faster than the conventional machines. This, in fact, is claimed to be the only machine in India capable of producing nails from stainless steel, aluminium, and copper, apart from iron.

So, who and what made this happen? Univenture Corporation is a subsidiary of the MHA Group of Companies headquartered in Nagpur. It was established in 2008 as a manufacturing company for wire products, especially wire nails, in the brand name 'Nag' under which the MHA Hardware Division has been marketing nails for over 25 years. The company started with the production of a mere 30 MT per month in 2008, catering to the local demand in Nagpur. Since then, it has shown unprecedented growth by doubling its turnover year after year.

"The introduction of the Enkotec MI01 nail manufacturing line will further strengthen our growth to new levels. Thus, the estimated production in the financial year 2011-2012 is expected to increase by over 200 per cent," says Mr Huzefa Husain, Director, Univenture Corporation.

Univenture has been a leading supplier to most industries in central India as well as construction and trading houses. The company employs four skilled and ten unskilled workers in the manufacturing unit working two shifts of eight hours each, six days a week. It produces wire nails from 2 mm to 4 mm in various lengths and recently has expanded its range to panel pins.

Speaking about the advantage of producing wire nails in Nagpur, Husain says it could be attributed to the ample availability of cheap raw material since this part of the country is a steel manufacturing hub of India.

With the arrival of the MI01, Univenture intends to revolutionise the wire nail market by setting up new benchmarking levels for quality. "Using the Enkotec nail manufacturing machines has been an opportunity to change the way the Indian market looks at the wire nail industry. We inaugurated the machine with a seminar on March 23 and all those who had been invited for the event were impressed with the quality and the speed with which the nails were produced," Husain states.

"The Enkotec machines in the long run can cut production costs substantially and will help us ramp up the production of wire nails. These lines will also reduce labour and subsequently reduce human errors or accidents. Such modern technology in manufacturing is the need of the hour in India," he adds.

A word about Enkotec: Headquartered in Denmark, the company undertakes development, production and sale of machines and tooling for the manufacture of nails.

"When it comes to the bottomline, it is the price for producing one tonne of nails, in the best quality, that counts. Therefore, Enkotec has been making continuous design and material improvements, always endeavouring to meet customer requirements for increased cost-efficiency and user-friendliness," says Mr Jesper Bendix, Area Sales Manager, Enkotec.

The Enkotec rotary forming principle makes it possible to produce high-quality nails at an unprecedented speed, while requiring less space and fewer operators and offering the possibility of unmanned production.

"Furthermore, this machine concept allows implementing an environment-friendly production with a low noise level, small energy consumption and an oil-free manufacturing process, eliminating the need for subsequent nail tumbling. MI01, intended for small and mid-size capacity needs, is a very strong alternative for its customers' capacity needs, whether they produce one single nail type or several different nails.

The MI01 combined with its high-end NX01 series, featuring a production speed of up to 2,000 quality nails per minute and covering nails of ?1.8-4.2 mm x 32-130 mm length, allows Enkotec to offer a complete range of nail machines, where many tooling parts are common for all machine models, thus increasing their cost-effectiveness," Bendix explains.

Enkotec's thread rolling machine, type TA01, has been specially designed for making high-quality screw shank or annular nail profiles with a production speed of up to 2,500 nails per minute. The working area of the TA01 is ?1.8-4.2 x 32-105 mm nail length with a profile height of 27-76 mm. The machine is capable of running in-line in a nail manufacturing line or as a stand-alone machine. The latest innovation from Enkotec is its movable stand-alone packaging machine, type NCP02. The system offers the possibility of in-line nail production in a complete, automated nail manufacturing process. The NCP02 automatically feeds the nail cartons, fills them with the accurate number of nails, and transports the nail cartons via automatic drive belt conveyors.

As to what attracted Enkotec to India, Bendix states: "With a geographic size similar to Europe and with 1.2 billion people, India is an interesting market for us. Moreover, over the last 2-3 years there has indeed been a shift in the world nail market, both geographically and with regard to the production set-up, moving towards bigger production sites.

So far the Indian market has mainly consisted of many small nail producers, producing for the local region, but now many of the manufacturers have started producing and selling nails in other regions, or are considering exporting nails to other countries. This means a need for bigger tonnages in short time and higher requirements for cost-efficient production and for quality nails to be used, as for example in pallets or automated nail guns."

Elaborating about this joint venture, Bendix says, "Enkotec started its co-operation with Univenture last year due to our new partner's vast knowledge of the nail market in India, especially in the state of Maharashtra. Through Uni-venture's professional organisation and experience in dealing with Western cultures, the set-up for Enkotec was perfect. We are looking forward to a long-term relationship with our agent and see a big future for both companies in India."

(Contact: Univenture Corporation, Tel: 0712-3192151, 3192152, 9373242626. Fax: 0712-2594535. Email: enkotec@univenture.co.in)

Related Products

Fieldpower Power Bus System

Weidmueller Electronics India offers FieldPower power bus system.

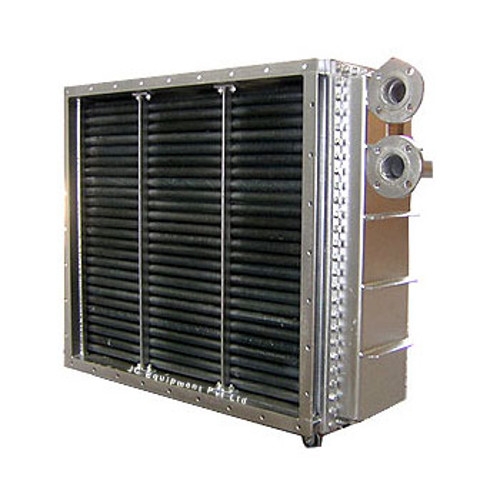

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Ceramic Reinforced Grinding Wheels

Rüggeberg GmbH & Co KG,

PFERD-Werkzeuge, has launched new reinforced grinding wheels with ceramic oxide

grain.