Schedule a Call Back

Multi-Function Metrology Instrument

Technical Articles

Technical Articles- Jul 19,12

Assuring high accuracy with low noise, Talyrond 500 Series from Taylor Hobson measures roundness, form and surface finish

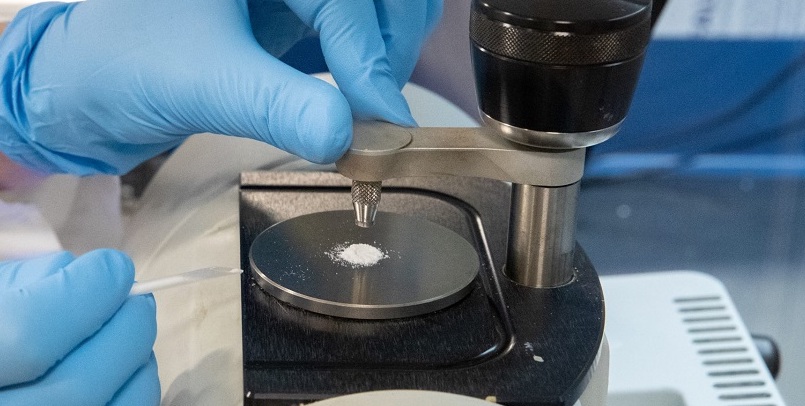

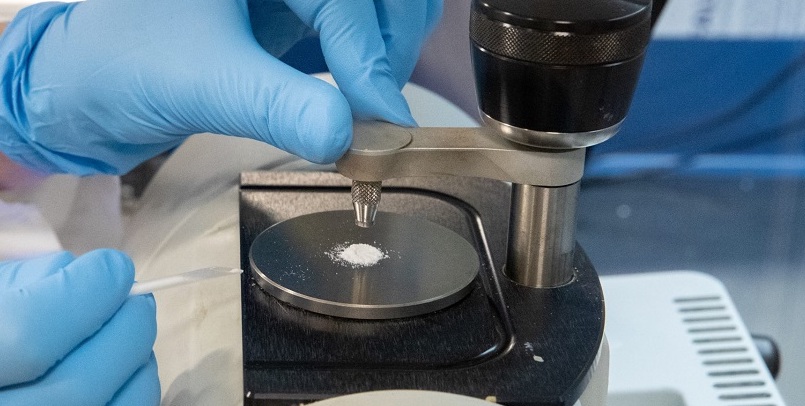

A new metrology instrument from Taylor Hobson (www.talyrond500.com) measures roundness, profile and surface finish on a single platform with high accuracy due to an extremely low noise floor.

By performing three precision measurements on one instrument, the Talyrond 500 Series offers a significant cost and productivity advantage over traditional single measurement instruments. Its ultra-low gauge resolution of 0.3 nm assures sufficient integrity for the most critical applications in a wide range of industries including aerospace, automotive and medical. Any cylindrical or round parts can be measured with high accuracy, including precision bearings, spindles, fuel injectors, crankshafts and turbochargers.

Rotary, vertical and horizontal datums exceed the precision of the machine tool's movement, allowing the instrument to exactly reproduce the work piece shape. Use of traceable standards and exclusive algorithms effectively eliminates instrument influence from the measurement results. Measurements can be exported to statistical process control systems that maximize production efficiency and reduce maintenance costs.

Talyrond 500 Series instruments do more than detect out-of-specification parts; using multiple analysis methods, they can identify location and cause of imperfections, allowing users to speedily correct them.

A unique calibration routine allows correction for stylus motion and tip correction. This allows measurement of angle, radius and form with respect to the part axis. Calibration, centre and level functions and measuring routines are all performed automatically. Simplified teach and learn programming, comprehensive user prompts and on-screen instructions support error-free performance regardless of operator skill.

All axes of the 500 series are controlled for waviness, straightness and noise, whether using the spindle, column or arm. The frictionless air bearing spindle and precision column assure high accuracy roundness, cylindricity and straightness measurements, resulting in higher efficiency and reduced scrap.

Applications include:

- Automotive & parts

- Aerospace

- Bearings

- Machine tools

- Metalworking

- Medical

- Optics

- Agricultural machinery, and

- Marine.

Taylor Hobson is a leading manufacturer of ultra-precision measurement instruments for a wide range of markets including optics, semiconductors, manufacturing and nanotechnology research. It is a unit of AMETEK, Inc., a leading global manufacturer of electronic instruments and electromechanical devices with annual sales of US$3 billion.

India contact: taylor-hobson.india@ametek.com

Related Products

High Speed Tripping Relay Two Element Relay - Jrv 181x2

JVS Electronics Pvt Ltd offers a wide range of high speed Read more

Plenty of Motion Possibilities in a Compact Housing

B&R Industrial Automation offers a wide range of plen Read more

High Speeed Tripping Relay Three Element Relay

JVS Electronics Pvt Ltd offers a wide range of high speed tripping relay three element relay - JRV 181x3.