Schedule a Call Back

M+C Schiffer Manufacturing Million Toothbrushes a Day

Technical Articles

Technical Articles- Sep 10,13

One million toothbrushes, 24/7 - a daily routine that relies on electrical automation Background

Every day we make use of some objects without giving them much thought, and the same goes for how they are manufactured. The production of toothbrushes, for example, requires the use of a very mature technology and a great deal of know-how and involves a precisely coordinated chain of different processing stations: the production process integrates injection moulding machines, handling systems as well as processing and packaging machines.

M+C Schiffer, based in Neustadt near Cologne, is an internationally recognised innovator in toothbrush production, and produces over one million toothbrushes a day in three shifts, seven days a week, on fully automated manufacturing lines.

They also develop new toothbrush models together with customers, and these include well-known companies and their brand products, such as GlaxoSmithKline with Dr Best Aquafresh and Sensodyne, Johnson & Johnson with Reach, P&G with OralB and Blend-a-mend, as well as discount stores and drugstores such as Aldi, Rewe, dm, Rossmann and Schlecker.

Challenge

To achieve a daily production of over one million toothbrushes, a highly reliable technology is absolutely vital. The time synchronisation of the process steps on the one hand, and the speed of individual processes on the other, present a particular challenge in the manufacturing process. Production at M+C Schiffer is fully automated in line, right through to packaging, as only a 'no human touch' production meets the hygiene requirements specified.

Multi-component injection moulding machines are used in the first production step to produce up to 32 toothbrush base bodies made from polypropylene (PP). The second component made from soft TPE is injected in the second operating cycle. This produces up to 80 toothbrush handles a minute. A handling system then transports the toothbrush base bodies to the bristle embedding plant. The specialist for this segment is Zahoransky, a group of companies based in Todtnau-Geschwend. The bristles, which are also called filaments, are embedded in every individual hole of the toothbrush bodies at a frequency of 1000 cycles a minute. The filament bundles are embedded using an anchor wire (flat type of special wire), which is punched into the recesses of the bristle carrier at high precision with the centrally folded filaments.

Depending on the type of toothbrush, up to 50 filament bundles in different lengths, colours and bundle positions are thus embedded in succession. In further production steps, the filaments are cut to defined lengths and rounded in multi-stage grinding processes.

Quality assurance is provided by a fully automated camera-supported control process, which ensures that only fault-free toothbrushes reach the packaging station. Transparent packaging film is given its final shape in the plastic thermoforming process. M+C Schiffer packs products in a range of different package variants in order to meet the relevant customer requirements.

Solution

The control of the entire bristle embedding system is handled by the Eaton XV102 HMI/PLC. The data exchange to the servo controllers, remote I/Os and operator display is implemented via CAN bus. An Eaton XP700 industrial PC with a 15-inch touch display is used for operation and assigning plant parameters.

The ruggedly designed infra-red touch display with safety glass ensures a high degree of reliability and meets specified hygiene requirements in accordance with the applicable food regulations.

Thanks to its compact housing design and small mounting depth, the touch display can be integrated ergonomically in machines and plants. Local programming access in the field is provided via Eaton RMQ-USB and RJ45 terminals (IP65). The integrated web server enables the controller to be accessed remotely.

Eaton's Galileo software is used for visualisation, and is an easy to learn and yet powerful project design environment. With its non-sector specific concept, Galileo offers seamless project designing for all XP/XV operator units from the Eaton HMI product range as well as for PC runtime solutions. Galileo always provides the project designer with the full functionality without any graduated restrictions on tags (variables) or screens, according to the performance specifications of the panel used. Users program the Eaton controller with XSoft-CoDeSys-2. This technically mature software based on the CoDeSys standard of 3S is impressive, thanks to its simple handling, and is well established in the automation world.

Results Andreas Walgenbach, project manager at M+C Schiffer, sums up as follows. "Our customers require just-in-time production for particular product launches or for special marketing campaigns. We then have to produce a specific number of products, often in the millions and deliver exactly on time. We can only keep to these delivery times if we can count on absolutely reliable production technology, components and suppliers.

We are regarded as highly reliable partners by our customers, and for this our thanks must also go to Zahoransky toothbrush machines and Eaton automation technology." Robert Dous, Director of Sales and Marketing at Zahoransky, adds, "Eaton's control and automation technology is an essential component in meeting the demanding requirements of toothbrush production at M+C Schiffer and ensuring highly reliable systems. Only in this way, can we meet our extremely high standards."

Related Products

Win Series Interface Relay Modules

Werner Electric Private Limited offers a wide range of WIN Series interface relay modules.

Centric Gripper

Schunk intec india offers a wide range of centric grippers-dpz-plus

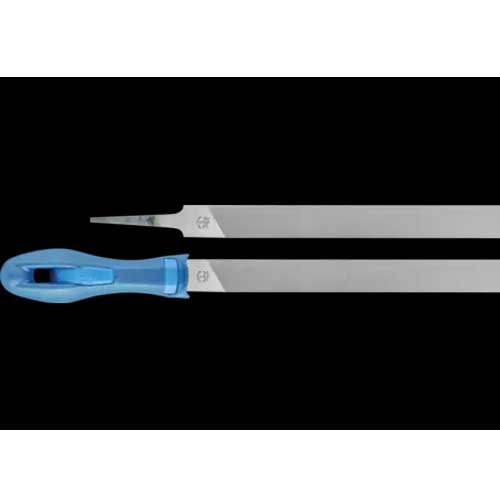

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.