Schedule a Call Back

Laser Welding

Technical Articles

Technical Articles- Jan 10,14

The PSM 400 BladeWelder from Schunk Laser Technology is a special laser beam machine for demanding materials. It can be used for crack-free, fast and cost effective processing even on high-temperature nickel or cobalt base alloys. With a maximum pulse power of 8 kW, the Lasag laser achieves a pulse energy of 110 J. Freely scalable pulse formation and modulation enable adaptation of the laser parameters to the specific characteristics of the materials. The pulse duration can be extended to a very impressive value of 200 ms. An adaptive closed-loop controller ensures precise and stable operation of the lamp-pumped solid state laser. To prevent damage to the fibres by a reflected laser beam when used on highly reflective materials, the BladeWelder is equipped with high-performance fibres that absorb such reflections. The other Schunk laser beam machines of the PSM 400 series are also extremely flexible, with three, four or five axes. They enable fast and convenient machining of both small and large components.

A machine table with electric height adjustment and double rotation and a sliding-rotating laser welding head provide for maximum flexibility in the work area. The operator has full access to all machining, programming and control functions, regardless of the component size. The user-friendly look-ahead controller and the unique teach function for line, arc, circle and spline allow fast set-up and programming of the laser beam machines. To ensure an optimal focal distance they can be equipped with mechanical (MDA) or laser-supported (LDA) distance adjustment. Schunk, as a competence leader for clamping technology and gripping systems, also provides peripheral devices for laser welding, such as the robotic interface VERO-S NSR. In the automated loading of laser welders, the compact, lightweight interface with minimal interfering contours allows pallet loading very near to the machine table. This enables the design of especially low clamping stations and pallets. The robotic interface can be combined with the flat palletising module VERO-S NSA plus, which enables a repeat accuracy of less than 0.005 mm with fully automatic pallet change, and can even be integrated directly in the machine. Both the VERO-S NSR and the VERO-S NSA plus self-lock via spring force. Pneumatic system pressure of 6 bar is needed for release.

(Schunk Intec India Private Limited, Bangalore. Tel: 080-40538999. Email: info@in.schunk.com)

Related Products

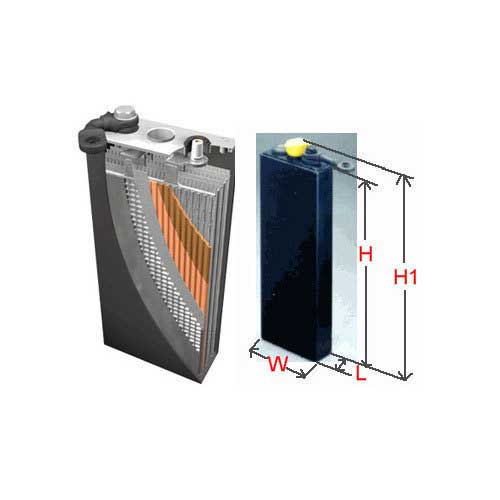

Forklift Battery

Aatous International is a manufacturer and solution provider of a wide range of forklift battery.

Impact Crusher

Laxmi En-Fab offers a wide range of impact

crusher.

Stationary Concrete Batching Plant

Nilkanth Engineering Works offers stationary concrete batching plant.