Schedule a Call Back

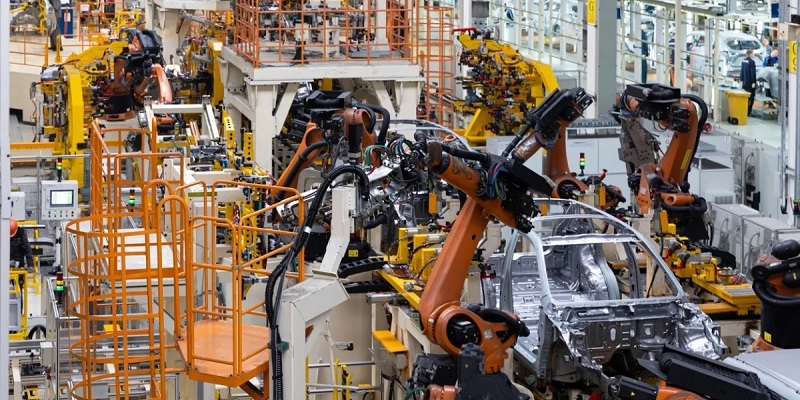

Industrial safety & security: Huge scope ahead

Technical Articles

Technical Articles- Mar 01,17

While earlier the installation of safety and security equipment was considered an unproductive expenditure, it is now an integral part of production management.

O n May 26, 2016, a powerful blast in a chemical factory located near a residential area in a Mumbai suburb killed five people and left 92 injured. The factory building collapsed after the fire and residents living nearby complained of breathing problems from the smell of the gas that was released. Twenty fire brigades and 15 ambulances were sent for the rescue operation. This is not a solitary instance of an industrial mishap. Disasters such as these take place on a regular basis across the country, putting the lives of people at stake apart from causing losses running into huge figures. The unfortunate part is that even if there are statutory guidelines that must be adhered to by all industries to prevent such mishaps, they mostly remain on paper. Industrial safety, in fact, is still not being seen as a serious issue.

Changes, however, may be in the pipeline. In a recent two-day workshop on safety excellence for business sustenance in the active pharmaceutical ingredients (API) industry organised jointly by the factories department and National Safety Council, Andhra Pradesh Chapter held at Visakhapatnam, it was announced that the factories department is proposing to establish industrial emergency response centres in industrial clusters with the support of managements. “The aim of this move is to help in monitoring safety compliance in factories,” said director of factories G Bala Kishore. He said these centres can also be used for interactive meetings and training programmes and to discuss issues related to occupation safety, health and accidents.

Stating that accidents mainly occur due to systems failure and human error, Kishore stressed on implementing a total safety management system including designing for safety and accident prevention. He further elaborated that human error is a major contributing error in most of the accidents, which depends mainly on the attitude of the personnel. He explained that the department is focusing on safety education by way of training programmes. Persuasion, motivation and finally penalisation as a last resort, is the approach of the department towards prevention of accidents, he said.

Of all the industries, the chemical industry uses most of the hazardous chemicals having a significant bearing on safety, health and environment problems encountered in running any industry. Although there is no universal consensus as to the scale of production and use of chemicals, it is estimated that the average annual world production of chemicals is more than 400 million tons. As per a document of 1987 published by the International Labour Organization (ILO), as back as in 1978, the American Chemical Society’s Chemical Abstract Services identified 4 million distinct chemical compounds and it has been calculated that this number is increasing at the rate of over a quarter of a million every year. It is accepted that few of these substances and compounds are used commercially. ILO’s book, titled ‘Occupational Exposure Limits for Airborne Toxic Substances’, lists occupational exposure limits for 1,178 chemical substances which have been adopted by various countries. This number constitutes but a small fraction of chemicals in use.

As per a report published by R R Nair, an expert in occupational safety, health and fire protection, in India approximately 10 million persons are employed in various factories. As per the Directorate General Factory Advice Service and Labour Institutes (DGFASLI), more than 36,500 hazardous factories out of the 3,00,000 registered factories, employ 20,46,092. No data is available for the occupational ill-health or injuries caused in the chemical industry in India. However, the current burden of accumulated occupational diseases in India is estimated to be about 18 million cases. Harmful chemical pollutants in the workplaces may be generally categorised into three different groups: (a) toxic chemicals, (b) flammable chemicals, and (c) explosive chemicals. The exposure of these chemicals can lead to many hazards, which can be broadly be grouped into two viz.: (a) toxic hazards and (b) fire and explosion hazards.

As far as India is concerned many provisions relating to chemical safety have been incorporated in the existing legislations after the Bhopal tragedy. The Factories Act, 1948, which is mainly concerned with factories, has been amended to incorporate many provisions relating to chemical safety. The Government of India has even formulated a new act i.e. Environment (Protection) Act in 1986 and a series of legislations have been brought under this Act. In view of the appearance of health hazards associated with particular chemical substances, specific laws have been passed by different countries or rules formulated under existing general legislation.

The law and practice regarding waste disposal within the enterprise differs markedly from one country to another. In the United Kingdom, disposal of waste within the enterprise is provided for in several acts of legislation notably the Health and Safety at Work Act 1974 and the Public Health Acts. The control of waste in general is mainly dealt with under the Control of Pollution Act 1974. The EC has directives on waste disposal. In India the control of waste in general is mainly dealt with the Hazardous Wastes (Management and Handling) Rules 1989.

Overall, it is this need for safety that has triggered the security industry in India. For instance, over the last decade, India has witnessed a substantial increase in terms of awareness about fire safety and security. The rapidly expanding IT and retail markets across the country have significantly contributed towards the growth of the fire and safety equipment sector, and this trend is likely to continue over the coming years. As large refineries, petrochemical complexes, biotechnology ventures, pharmaceutical, automobile, steel, oil and gas exploration projects need to comply with various mandatory safety regulation, these segments have been contributing hugely to the growth of the country’s fire and safety market. However, the market potential is still largely untapped due to lack of awareness, stringent regulations and a common perception of fire safety equipment being perceived as an unproductive outlay.

According to ‘India Fire and Safety Equipment Market Forecast and Opportunities, 2019’, the fire and safety equipment market in India is expected to grow immensely over the coming years. The market revenues of India’s fire & safety equipment market are expected to reach USD4.94 billion by the end of 2019. The market is being driven largely by the small players with restricted regional presence and involved in offering comparable products at lower prices compared to major organised players.

As far as the security equipment market is concerned, the installation of CCTVs has become the most widely accepted solution. As Dipesh Panjwani, Director, MX MDR Technologies Ltd, makers of a wide variety of CCTV cameras, puts it, “Security is a growing demand everywhere, be it in industries, offices, retail markets, homes, etc. As such, the variety of CCTV cameras and other equipment now available is quite huge and made to suit every kind of budget.” In this market, ccHDtv is a novel technique pioneered by ITE Tech Inc. The ccHDtv cameras transmit compressed H.264 data to NVR units. The technology is similar to that used in digital television broadcasts. This is a proven way of delivering stable high quality video transmission on a large scale.

Data is transmitted via standard analog video coaxial cables with up to 16 cameras sharing a single cable. The most obvious advantage of this technology is that existing coaxial cable infrastructure for legacy analog CCTV systems can be used as the required coaxial cables and connectors for this technology are exactly the same. “One of the unique features of this technology is the ability to create flexible daisy chain connections using BNC couplers and cameras set to operate on different channels. Adding new cameras can therefore be achieved simply by inserting a T connector and connecting a camera on a non-conflicting channel. Loops can even be formed as a fail-safe measure against broken cables. As a result, ccHDtv systems have the potential to be scaled easily with a high level of stability,” elaborates Kiron Kunte, who has over 35 years of design and solutions experience in security, telephony and networking infrastructure.

Meanwhile, safety is now a prime feature of the way industrial units are designed and constructed. As Nair has stated in a published article, “An applicable egress strategy is considered as one of the key fire safety aspects, especially in high rise buildings. As occupants increase, the time taken to evacuate the building will also increase. It may be remembered here that above certain heights, the vertical distance to be travelled by an occupant may subject them to additional risks. In such cases, the egress system may require re-evaluation in order to consider alternate strategies, such as relocation, refuge areas, role of elevators, etc. The stairways, separate fire compartments, areas of refuge, etc. are all examples of places of relative safety. It may be reminded here that an ideal place of relative safety or ultimate safety is a location outside of the confines of the building at street level.”

Commenting on the state of the industrial safety and security industry in India, Jitendra Singh Rathore, proprietor of Delhi’s Rathore Infosecuricomm, says, “The security industry is growing rapidly in India. Organisations are looking forward to enhancing security through surveillance solutions, bearing in mind organisational and employee safety. Solution-wise, the market is moving from analog to IP solutions with web-based applications and centralised monitoring systems. Quality solutions with maximum use of IP technology are in demand as compared to regular lower-end solutions.”

New Technologies

Given the rise in demand for security products related to ensuring industrial safety and disaster management, several companies are now investing in research and development. Marvel Gloves Industries, for instance, has introduced seamless knitted gloves, which are manufactured on automatic glove knitting machines and are available with different thickness, lengths and various gauges like 7,10,13,15 made from different fibres: cotton, cotton/polyester, synthetic blends, acrylic and nylon. The seamless construction and close flexible fit increase the dexterity, allow the circulation of air and reduce perspiration.

Leading fire detection specialist, Apollo Fire Detectors, has launched a new range of intelligent interfaces designed to complement its full range of fire detection devices. The new range, which meets EN 54-17 and EN 54-18 standards, is the latest addition to the range of CoreProtocol® enabled devices following the launch of the new Apollo SOTERIA® detectors earlier this year. All devices are backwards compatible but, when used with CoreProtocol®, provide enhanced functionality and individual module configurability to enable advanced programmable features.

Karam Industries, a leading manufacturer of protective equipment, has now come up with a range of safety equipment designed especially for women. The company has launched these products as there is an increase in participation of women in the manufacturing sector. These include safety helmets, full body harnesses, safety shoes, safety spectacles, etc. Flir has launched the FLIR K2, a rugged, reliable, and economical thermal imaging camera that is specially designed for fire fighting applications and severe conditions. Producing thermal images at 160 x 120 pixel resolution displayed on a bright 3” screen, the K2 helps fire-fighters find their way through thick smoke, assess situations with confidence, and expedite decisions.

– HUNED CONTRACTOR

Related Stories

Importance of preventative maintenance in industrial settings

To enhance the effectiveness of preventative maintenance, industrial facilities are increasingly turning to advanced technologies such as thermography.

Read more

Zetwerk wins second order from NTPC Renewables for solar PV modules

The new order is for 1515 MWp solar PV modules.

Read more

Kinetic Green appoints Manav Mehra as senior executive VP of 2-wheeler SBU

His focus will be on expanding the dealer network, boosting market penetration, towards service and sales excellence, and strengthening brand presence across the country.

Read moreRelated Products

Oil Mist Collector System / Oil Fumes Extraction Systems

Amaricar Engineering & Systems Pvt Ltd offers a wide range of oil mist collector system / oil fumes extraction systems.

Air Pollution Control System

Hindustan Engineers offers a wide range of air pollution control system.

Industrial Vacuum Cleaner

Maxtech Engineers offers a wide range of industrial vacuum cleaner.