Schedule a Call Back

Industrial growth drives hydraulics demand

Articles

Articles- Mar 30,24

The growth in mining and construction industries, agricultural automation, and the expansion in the manufacturing sector are increasing the demand for hydraulic machinery. Manufacturers of hydraulic equipment have implemented several strategies to improve their product offerings and provide better customer service to meet the rising demand. Such tactics encourage the market's expansion by increasing demand for hydraulic equipment with cutting-edge technology.

According to Straits Research, the global hydraulic equipment market - worth $ 43.825 billion in 2021, is estimated to reach $ 62.375 billion by 2030, growing at a CAGR of 4 per cent during the period (2022 - 2030).

There are multiple factors driving the demand for hydraulic equipment such as:

- Adoption of mechanised agricultural equipment: Agriculture has been a fundamental and significant business across the world for ages. Various activities such as ploughing, sowing, fertilizers & pesticide spraying, harvesting, and different processes were carried out manually in older times. With the increase in industrialisation and the invention of various novel equipment, farmers prefer using machines for agriculture-related activities. Advanced equipment such as atomized tractors or harvesters is used in agriculture activities to increase efficiency and save high labour costs. Adopting automation and machinery in farming is likely to boost the growth of the hydraulic equipment market.

- Increase in industrialisation: The rise in industrialisation in developing countries is propelling the requirement for hydraulic equipment. Industries such as mining & construction, packaging, material handling, etc require equipment that can handle heavy operations. Hydraulic motors, pumps, valves, cylinders, and actuators can carry out heavy-duty operations with higher speed and efficacy. Thus, hydraulic equipment or components are an ideal and reliable option for various industry functions. Companies such as Bosch Rexroth, Daikin, Eaton, and Parker Hannifin offer hydraulic-operated machines, including motors, pumps, cylinders, valves, steering, seals, press machines, lifts, and cylinders according to the application in the respective industry. Companies continuously adopt atomisation for efficient working, and thus advanced versions of hydraulic machines are witnessing huge demand. This acts as one of the primary drivers of global hydraulic equipment.

Asia-Pacific to lead the market

Asia-Pacific - the leading revenue contributor to the global hydraulic equipment market – has been witnessing high growth, owing to a high population base in countries such as China and India. The region is expected to grow at a CAGR of 4.5 per cent. The consumption of FMCG products has increased significantly in this region over the last few years, which drives market growth. In addition, the rapid development of the manufacturing, construction, mining, agriculture, and transportation industries boosts the demand for hydraulic equipment. Owing to this increased demand, manufacturers have set up manufacturing plants to meet the growing requirement in the region. Key players have adopted various developmental strategies to strengthen their foothold in the market.

North America - the second largest region - is estimated to reach $ 14.508 billion by 2030, growing at a CAGR of 3.5 per cent during the period of 2022 to 20230. Rapid development has been witnessed in North America's food & beverage, pharmaceutical, and FMCG industries over the past few years. With the increased demand for FMCG products, new manufacturing plants and the expansion of old factories have increased the demand for hydraulic-operated filling and packaging machines. Hydraulic motors that operate conveyors are used in food & beverage while filling the containers such as bags and sacks.

A rapid increase in the requirement for packaged food & beverage, pharmaceutical, and FMCG products is pushing the demand for hydraulic equipment in Europe. In addition, the rise in the number of projects carried out in construction, forestry, mining, agriculture, transportation, and other manufacturing industries has driven the demand for hydraulic equipment in Europe.

Industrial segment continues to dominate

Of the two markets of mobile and industrial (based on application), the industrial segment is the highest contributor to the market, with an estimated growth rate of 3.7 per cent CAGR. Hydraulic equipment are widely used in various industries due to their easy controlling, simple operation. Industrial hydraulic equipment are used in various industries such as packaging, food & beverage, rubber, paper, printing, plastic, and press. For example, using dyes, hydraulic press machines are used in sheet metal press workshops to mould the sheets in desired shapes. In addition, sheet metal bodies of cars are shaped using hydraulic press machines.

In material handling sector, hydraulic equipment, including aerial maintenance platforms, hydraulic stackers, floor cranes, and drum lifters & tilters, are used to transport the material from one location to another. Similarly, hydraulic finds application in paper cutting machines, printing machines, rubber molding machines and packaging machines (used in the food & beverage and pharmaceutical industries). These machines use hydraulically operated equipment such as motors, pumps, cylinders, actuators, and pumps.

Mobile hydraulic equipment includes movable equipment operated by hydraulic motors, drivers, pumps, or cylinders to carry out their work. For example, construction, mining, agricultural, marine, and forestry are the industries where movable equipment such as excavators, loaders, dump trucks, tractors, dryers, sprayers, rotary cutters, mini excavators, and wheel loaders are used. A significant increase has been witnessed in construction and mining projects globally; thus propelling demand for mobile hydraulic equipment.

Mining & construction segment is the leading user of the hydraulic equipment and is expected to grow at a CAGR of 3.4 per cent in the next 5-6 years. Manufacturers are introducing improved solutions, various excavators for specific requirements, and enhanced technology and fuel efficiency to reduce operating costs and increase productivity.

Based on product, the global market is fragmented into pumps, motors, valves, and cylinders. According to Straits Research report, the cylinders segment is the highest contributor to the global hydraulic equipment market and is estimated to grow at a CAGR of 3 per cent from 2022 to 2030. Advanced cylinders give more stability to hydraulic equipment while handling heavy loads.

Electro-mechanical system as an alternative

Electro-mechanical systems are rapidly replacing hydraulic equipment. This is attributed to the fact that electro-mechanical-operated equipment offers numerous advantages over hydraulic equipment. For instance, an electro-mechanical system is cheaper than a hydraulic system when the requirement of ancillary hydraulic equipment is considered. In addition, these systems require less maintenance and repair, as there is a low risk of leakage. Furthermore, electro-mechanical systems only use power while moving the load. In contrast, hydraulic systems have to maintain pressure levels of operating fluids to maintain the position while holding the load, which can cause a delay in responding to the commands given by the operator. This acts as a restraining factor in the hydraulic equipment market.

Growing need for energy-efficiency

Energy consumption by hydraulic equipment is the primary concern, which incurs additional overall costs of purchasing and operating industrial plants and machinery. As the pressure in hydraulic equipment is high, a considerable amount of energy is consumed, which, in turn, increases energy costs. To curb additional costs, energy-efficient hydraulic equipment is deployed. In addition, various new advancements in hydraulic technology have increased its efficiency. For instance, variable speed pump drives in plastics processing machines reduce pressure holding losses during pauses and partial load operation. Similarly, variable pump and valve systems that allow electronic flow matching minimize losses.

Thus, the introduction of advanced energy-efficient hydraulic equipment by manufacturers is anticipated to create a lucrative opportunity for the growth of the global market in the coming years.

Article Courtesy: Straits Research

Hydraulic machines are those that operate with the assistance of liquid fluid. The hydraulic liquid is pumped to cylinders and motors through the machine and is pressurized while accounting for resistance. The liquid is further distributed through pipes, hoses, or tubes after being controlled by the valves. One ON/OFF button is needed to operate the system. Additionally, the system is lighter because no gears or levers are used in the process. Regardless of changes in operation speed, hydraulic equipment maintains a constant force.>

Related Stories

Tata Motors wins 1,297 bus chassis order from UPSRTC

The Tata LPO 1618 diesel bus chassis is developed specifically for intercity and long-distance travel.

Read more

Isuzu doubles production, rolls out 100,000 vehicles in two years

Isuzu’s journey in India began in 2016 with the establishment of its Sri City facility.

Read moreScania India and PPS Motors inaugurate training facility in Chandrapur

Additionally, the centre employs innovative technology in mining and is supported by two technical trainers and one driver trainer, aiming to strengthen Scania India’s presence in India.

Read moreRelated Products

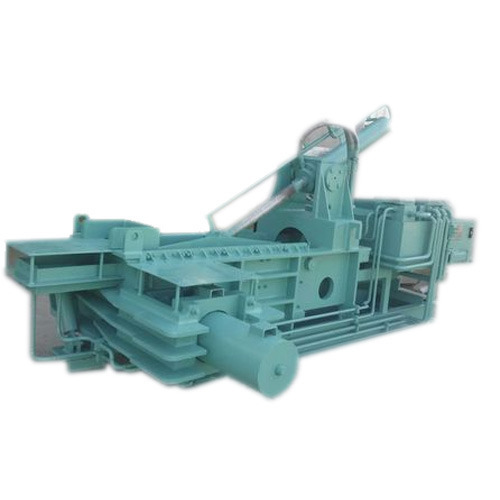

Baling Machine

Mask Hydraulic Machineries provide triple action scrap baling machines. Read more

Manifold Block

Om Shakthi Hydraulics offers a wide range of hydraulic manifold blocks. Read more

Exclusive Hydraulic Fittings

Supreme Engineers is engaged in manufacturing and supplying an exclusive range of hydraulic fittings. Read more