Schedule a Call Back

Indo Air Compressors

Technical Articles

Technical Articles- Oct 03,13

A Remarkable Journey

Starting as a manufacturer of compressor parts for OEMs in the year 1977, Indo-Air Compressors Pvt Ltd ventured into making its own brand of compressors and vacuum pumps in the year 1998, in the range of 1 to 300 HP. The first compressor with Indo-Air brand was produced in a portion of the group company "Manilal & Sons" established in 1984 to cater to the heavy machinery manufacturers to supply heavy components.

Within a few years the demand for 'Indo-Air' brand compressors increased and the company had to establish its own facilities. Indo-Air established its most modern factory at Kathwada Industrial Estate in Ahmedabad, spanning across an area of 6300 sq.mtr. Keeping its focus towards quality and new product development the new factory made its in-house facilities comparable to world class establishment.

The Facilities

All internal assemblies are carried out in a dust-free closed assembly room to protect the internal moving parts. The room is adequately furbished to have the necessary tools, test benches, air lines and inspection facilities. The assembly of the compressors is done by experienced and highly skilled work force. The quality plan for the assembly is displayed at every stage of the compressor assembly to ensure repetitive set performance of the compressors.

All compressors leaving the premises of Indo-Air are tested for performance, efficiency and quality. Every model of the compressor is tested once in two months in a test bed, established specially for this purpose with calibrated instruments and measurement devices, where the nozzle test at various parameters as specified in the relevant Indian Standard is carried out for a recheck.

Breakthrough Products

With the customer demand for more efficient compressors growing in India, Indo-Air started the manufacture of rotary screw compressors in the year 2010. The company had to compete with other international players who have had a standing of more than 4 decades. Due to the technology of Indo-Air screw compressors and the compact design and positioning of various elements of the compressor, Indo-Air compressors were immediately accepted by the Indian customers.

Within 3 years there are more than 100 compressors running successfully in the field. The performance of screw compressors up to 75 HP range prompted the company to launch other higher models of screw compressors up to 300 HP.

Improvisation and meeting the customer requirements are the motto of Indo-Air. With these in view when the demand for higher flow at high pressure became the need, Indo-Air came out with twin reciprocating compressor technique.

Catering to hospital needs of air systems has been with Indo-Air for many years. To meet the clean oil-free air of the hospitals Indo-Air came out with its NL type compressors well received in the market. Indo-Air Vacuum pumps have captured the maximum hospital demands.

100% Oil-free Air

The quest for a reliable 100% oil free quality air has prompted Indo-Air to come out with totally engineered, tested and high performance range of compressors. To ensure the product quality in the production of PET bottles, containers for home care/cosmetic products, food products, pharmaceutical products, usage in aeronautics, turbine and hydraulic circuit pressurising and pharmaceutical industries, Indo-Air has developed its new IAH series compressors.

To meet the needs of user application and customer requirements Indo-Air, while designing the IAH series compressors, has focused on the quality and protection requirements and is offering high quality oil-free air from its IAH series water cooled compressors

Types of Compressors

Indo-Air has an entire range of compressor and vacuum pumps catering to most of the needs of different industries and applications. The piston type reciprocating compressors range from single-stage for low pressure application; two-stage models for medium pressure application and the high pressure models of multi stage models. The connected load of the compressors range from 1 HP to 60 HP

The state-of-the-art rotary screw compressor, with its low noise level ideally suitable for installation within the factory area, is much sought after by the industry in recent times. Indo-Air makes the screw compressor from 7.5 HP to 100 HP now and plans are afoot to manufacture up to 300 HP.

Reciprocating type compressors in oil free version from 0.5 HP to 15 HP are also available for the industry where the air is required completely oil free. This has a special application in the hospital use. The other products from Indo-Air are the vacuum pumps from 2 HP to 10 HP and heavy-duty water cooled vertical compressor from 25 to 60 HP. The latest addition to the entire range is the high pressure water cooled oil free IAH series compressor from 40 HP to 150 HP.

Areas of Applications

Indo-Air compressors are used in pneumatic press, road building machines, ceramic, pneumatic tools, service stations, pharmaceuticals, polymer processing machines like PET bottling plant, injection moulding machines and extrusion plants, air blast circuit breakers, oil exploration, cleaning, spray painting and various other applications. The vacuum pumps and oil free compressors are a must in hospitals and industry requiring clean air.

Preferred Choice of Customers

Over the decades the customers have given preference to Indo-Air compressors due the international quality standards of manufacturing; the organisation system, which ensures quality checks at every stage of the manufacturing process; and the best and reliable sources of supply and a vast aftersales network all over India.

The products are of highest quality of international standards and comparable with those from other Indian companies producing international brands. Indo-Air products are best in price in terms of quality. The company has good sales and service network all over India and the services are provided within 24 to 48 hrs. It has a team of experienced and qualified engineers in the organisation.

Achievements Galore

Indo-Air has the best range of products to meet almost all the needs of the customers and its continuous effort to bring out new products with enhanced capabilities. The company's export business has been constantly on the increase through the last decade and its compressors are now exported to Asian, African, European, Arab countries and South East Asia and Australia

According Mr C M Panchal, Managing Director of Indo-Air Compressors Pvt Ltd, and a technocrat with more than 30 years of experience in compressor industry, the present economic slowdown has not affected the business of Indo-Air. It has performed better than the previous years due to sustained marketing efforts and cost reduction exercise. The compressor buying process, according to Mr Panchal, is no longer an off-the-shelf purchase. A lot of technical factors are to be considered before deciding on the type and size of the compressor for each application. His technical team has been trained to advise the customers and guide them in selecting the appropriate compressor for their requirement.

(Indo-Air Compressors Pvt Ltd, Ahmedabad. Tel: 079-22901951. Mobile: 099241-03612 Fax: 91-79-22901952. Email: info@indoair.com)

Related Products

Fault Annunciator

Insys Electrical & Controls offers a wide range of fault annunciator.

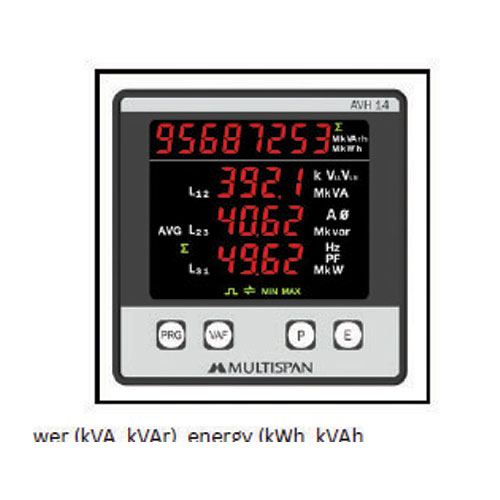

Multifunction Meter

Insys Electrical & Controls offers a wide range of multifunction meter.

Safcon Bolt Container Seals High Security Seal for Containers & Cargo

Safcon Seals Private Limted offers a wide range of safcon bolt container seals high security seal for containers & cargo.