Schedule a Call Back

India imports nearly 50% of its machine tool requirements: Sameer Kelkar

Interviews

Interviews- Dec 11,24

Related Stories

The machine tool sector is growing with rise in automation: Hrishikesh B Sawant

The Indian machine tool industry is currently growing, with a number of factors contributing to its expansion.

Read more

Sandvik Coromant to exhibit revolutionary tools at IMTEX 2025

IMTEX is the largest machine tool and manufacturing technology show in South and South-East Asia, attracting around 1,000,000 visitors and over 1,000 exhibitors from various industry sectors across ..

Read more

We plan to showcase our entire product range at IMTEX 2025: R K Purohit

Sphoorti's major USPs include its wide range of tool holders compatible with any CNC machine, ease of interchangeability, and a customer-centric approach.

Read moreRelated Products

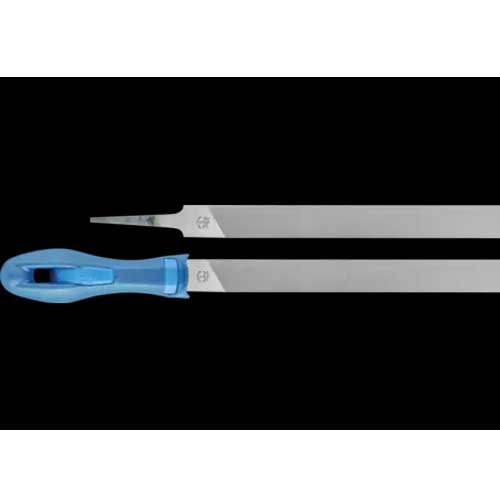

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.

Ss Hex Head Bolts

Trychem Metal And Alloys is offering SS hex head bolt.

Cutting Tools

Get Cutting Tools provides a wide range of CNC cutting tools