Schedule a Call Back

Hycontrol Contributes to Major Expansion at Wuhan Steel Mill

Technical Articles

Technical Articles- Oct 14,15

There were one thousand and forty-five steel companies in China in 2001. Thirty-four of which had production of more than one million tonnes a year. The top four companies, Bao Steel, Anshan Steel, Beijing Capital Steel and Wuhan Steel represent only thirty per cent of all of China’s steel production. The market has many small state owned steel companies but this is set to change.

To put this into perspective in the United States, the top six companies produce around fifty per cent of all domestic production. The percentage for the top five in Japan is seventy-five per cent and for the top three in Russia it is fifty per cent. POSCO alone produces sixty-five per cent of Korean steel while one major steel mill represents almost all the production of a whole country in France, UK and Italy.

Wuhan Steel, one of China’s top four steel giants, makes 6.6 mn tonnes through the efforts of one hundred thousand persons (66 T/person.year) while China Steel in Taiwan produces 9 mn tonnes per year with nine thousand employees (1,000 T/person.year). Wuhan Steel will have to let go of ninety per cent of its workforce if it wants to match China Steel’s standard.

Wuhan Steel is well aware that the key to their future is two fold: acquisition to increase capacity and automation to improve efficiency. To this end Wuhan Iron & Steel Group has acquired Liuzhou Iron & Steel Group for 6.5 billion Yuan, approx US $805 mn to own 51 per cent of the state-owned company boosting its production capacity by a third. Further investment has been made in the raw material handling plant and the massive waste water treatment plant at Wuhan to help handle the increase in capacity.

The Wuhan Steel Mill design institute selected Hycontrol for its Ultra Low Frequency Ultrasonic systems Microflex LR and Reflex LR for the raw material handling plant where 75 instruments were installed on the Iron Ore, Sinter and Coke bins in the preparation hall and 35 x Microflex-C in the Waste Water Treatment plant. The Ore bins proved to be the most difficult with range from 15 to 25m containing some of the harshest environments to be found in the industry. The 50m Coal and Coke bins proved not as difficult as the particle size was larger even thou the range was greater. To overcome the extremes of both dust and noise from the falling product frequencies as low as 5 kHz and 10 kHz had to be used. So difficult were these applications that the commissioning was carried out by Hycontrol engineers using the very latest Hycontrol communications system HGSML. This is a module, which is connected to the instrument loop allowing each instrument to be addressed, interrogated, programmed and commissioned from the Hycontrol HQ in the UK. The HGSML uses GPRS so the system is always on but is only charged when data packets are exchanged.

This makes commissioning not only very efficient but also inexpensive and overall contributes to Wuhan Steel’s drive for greater efficiency and automation.

Courtesy: Pune Techtrol Pvt Ltd, exclusive distributors of Hycontrol Ltd for India, Bangladesh & SriLanka. Tel: 020-66342900, 27121052. Fax: 91-20-66342998. Email: ho@punetechtrol.com

Related Stories

DCM Shriram to Acquire 100% Stake in 4 Industrial Salt Companies for Rs 1.75 Bn

The these salt works span over 1,077 acres and have a combined capacity of 0.21 million MT of washed industrial salt per annum, equivalent to around 13 per cent of the Company’s annual salt requir..

Read more

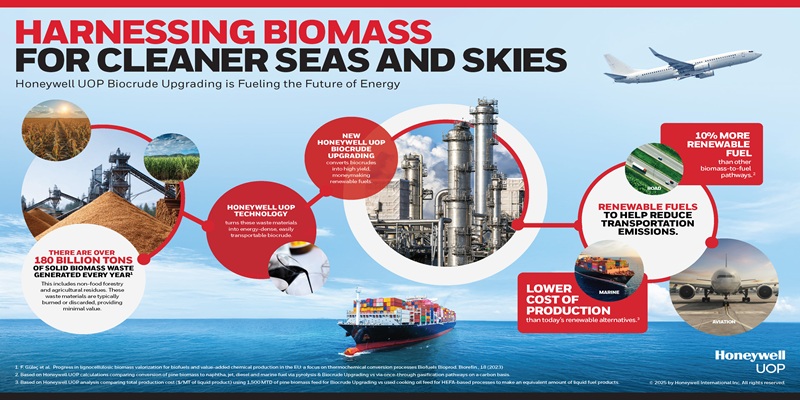

Honeywell Launch Biocrude Upgrading Tech for Sustainable Maritime Fuel

Honeywell’s new process technology enables biocrude to then be refined at major facilities to produce marine fuel, gasoline or SAF.

Read more

ABB India Upgrades Peenya Plant, Adds 25% VSD Capacity

The new line features a combination of advanced robotics and digital production monitoring technology, handling production of large batches with speed and precision and providing real-time visibilit..

Read moreRelated Products

Numerical Check Synchronizing Relay -jnf 060

JVS Electronics Pvt Ltd offers a wide range of numerical check synchronizing relay -JNF 060.

Kusam-meco” 1000v Dc Hand Held Digital Insulation Resistance Tester - Model- Km 372

Kusam-Meco has added a new hand-held digital insulation resistance tester cum digital multimeter for the convenience of electricians.

Single Pole Instantaneous /definite Time Earth Fault Relay -jrc 932

JVS Electronics Pvt Ltd offers a wide range of single pole instantaneous /definite time earth fault relay -JRC 932.