Schedule a Call Back

How will mobile connectivity impact manufacturing?

Technical Articles

Technical Articles- Oct 08,20

Related Stories

IMTEX Forming 2026: Charting the Next Chapter of India’s Metal Forming Ecosystem

IMTEX Forming 2026, Asia’s largest metal forming and manufacturing technology exhibition, is set to return to Bengaluru from 21–25 January 2026.

Read more

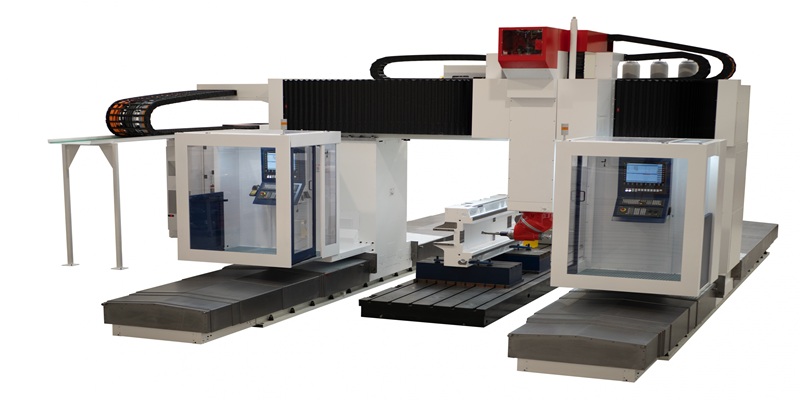

Powermill G3 HPC3 Showcases Italian Excellence in Large-scale Precision Milling

Combining robustness, precision and Industry 4.0 connectivity, the Powermill G3 HPC3 exemplifies Italian manufacturing excellence for large-scale, high-accuracy machining.

Read more

Hannover Messe 2026 to focus on automation & digitalization, adds Defense Area

At the upcoming Hannover Messe, AI will be a recurring theme throughout all the halls, and will play a central role on almost all stands.

Read moreRelated Products

Compact Fmc - Motorum 3048tg With Fs2512

Meiban Engineering Technologies Pvt Ltd offers a wide range of Compact FMC - Motorum 3048TG with FS2512.

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.