Schedule a Call Back

Hannover 2014 Stopping by the Road to the Factory of Future

Technical Articles

Technical Articles- Feb 26,14

On the cold morning of February 11, 2014, over 100 journalists from across the world gathered at Radialsystem V, Berlin - a former, century-old water pumping station, now functioning as a cultural centre "where new ideas 'radiate' out in all directions". An appropriate choice of venue for a sneak preview of Hannover 2014 arranged by the organisers, Deutsche Messe - for the world's largest technology trade fair is all about ideas. And when the event opens for the annual technovaganza at the Hannover Fair grounds next month (7-11 April, 2014), over a hundred thousand visitors from across the world would make the rounds of the various halls, absorbing the many innovations and tools available for them to incorporate into their businesses - for improved efficiency at reduced costs - a never ending quest in search of better productivity.

"(Hannover) 2014 will see a great shift towards automation in industrial manufacturing and the ongoing transformation of the world's energy systems," said Dr Jochen K?ckler, a member of the Managing Board of Deutsche Messe, presenting an overview of the trends and topics this year. To quote him: "to remain competitive, companies need to make their manufacturing processes more efficient, and that means greater investment in state-of-the-art automation technology. Their competitiveness also hinges on access to a reliable, sustainable energy supply. The world's leading providers of automation solutions and energy technology will be showcasing solutions to precisely these challenges at Hannover Messe 2014."

Dr K?ckler also hinted at the emerging trends, pointing out that with the low wages era in China coming to an end, it is a further boost for automation and hi-tech. Powered by shale gas and cheaper energy, the US is now looking at strengthening its manufacturing sector, both for creation of jobs and wealth. A team from Apple had visited the Hannover Fair last year and impressed by what it saw. And the outlook for Europe is positive with a 3% increase in growth predicted for Germany, he observed.

With Industrial Automation & IT, Energy & Environmental Technology, Industrial Supply and R&D among its keynote themes, "Integrated Industry - NEXT STEPS" is the overarching motto at this year's Hannover Messe.

Partner Country The Netherlands

Holland is the partner country at Hannover 2014. But Monique T G van Daalen, the ambassador of the Kingdom of The Netherlands to Germany, said that her country prefers to be called The Netherlands rather than Holland. With a centuries old trade association, The Netherlands is the largest direct investor in Germany, with the annual trade figure pegged at Euro 64 Bn. Stating that the Hannover Fair this year will be shining in bright orange, van Daalen highlighted her country's strength: high technology (microchips) and sustainability. The designing of the fastest solar car and futuristic bicycles also highlights the latter. Citing 'out of the box thinking' as the key to its success, van Daalen pointed out that today over 80% of all devices carry Dutch microchips. Also up to 20% of the components in the cars made in Germany are of Dutch manufacture.

About 200 Dutch companies are expected to participate in Hannover 2014, the number significantly higher due the partner country status this year. However with 82 companies in 2012 and 120 in the 2013 edition, the participation is also steadily increasing over the last three years.

German companies take pole position in the race for Industry 4.0, the fourth industrial revolution unleashed by smart technologies of the internet era

According to Dr K?ckler: "The Netherlands' mechanical engineering sector is enjoying steady growth and is made up predominantly of highly specialised small and medium enterprises. The country also has an extremely competitive industrial subcontracting sector which supplies components, modules and made-to-order solutions to customers all around the world. The Netherlands are also a shining example of European cross-border industry partnership. Exhibitors and visitors from around the world seeking cooperative ventures with Dutch companies in these sectors will be extremely well positioned to do so at Hannover Messe."

Industry 4.0 The Road to Future

The highlight of the preview was a very interesting presentation titled SmartFactoryKL - from Vision to Reality, by Prof. Dr-Ing Detlef Zuehlke, Scientific Director, Innovative Factory Systems (IFS) at the German Research Center for Artificial Intelligence.

Dr Zuehlke is also the Chairman, Executive Board SmartFactory e.V., a manufacturer-independent demonstration and research platform in which innovative ICT technologies and their use in a realistic industrial production environment are tested and developed.

Founded in the year 2005, SmartFactory was a response to the demand by more and more companies asking for customised solutions to specific demands. While there are concepts based on existing products and technologies, it is important to demonstrate these concepts can work in reality, and that is the challenge before the SmartFactory. Started with just 8 founders, today there are 28 partners and 12 sponsors in this project, including BASF, Beckhoff Automation, Belden, Cisco, Emerson Process Management, Festo, Harting, KSB, Lapp Kabel, Phoenix Contact, Rexroth, Samson, Siemens and Weidmueller.

So the concept has been around for some time. There was also the presentation by Dr h c Manfred Broy, Department of Software & Systems Engineering, Faculty of Computer Science, at the Hannover preview last year (Integrated Industry: The Fourth Industrial Revolution, IPF March 2013). But much progress has been made since, and the fourth industrial revolution is here; well almost. And based on what Dr Zuehlke presented, it was conceived by and will be birthed in Germany. It is pertinent to note that at the moment, the German scenario is one of a perfect synchronisation between politics, science and industry, making it the most fertile breeding ground for Industry 4.0.

But the question remains, as Dr Zuehlke himself alluded to the much touted 'smart refrigerator' fiasco to ask whether this is a case of much hype vs reality. Not so apparently, as the presentation elaborated. Because the drivers of this latest industrial revolution are rooted in reality, these being: individualised products demanding increased agility; shorter product life cycles demanding shorter set-up times (e.g., smart phone and other gizmos); easy plug 'n' play for managing complexity (e.g., the printers of yore compared to those available today); the worldwide competition requiring one to be faster and better; and job enrichment with employment for people.

Evolving from these drivers, the four key paradigms of Industry 4.0 are:

- The smart product - having an extensive memory with product, production and operational data

- The smart machine - being able to self-organise within the production network

- The smart planner - planning the production based on realtime production data, and

- The smart operator - as a creative planner, observer and decision maker.

This envisages a smart factory much like the Lego blocks assembly style. Machines will become Cyber-Physical Systems (CPS) - autonomic components with local control intelligence, which are able to communicate to other machines, production lines and products through open nets and semantic descriptions. This will call for much rationalisation as there are too many standards and data security risks with open standards. A rationalisation with right global tandards - physical (mechanical, electrical, pneumatic); communications; interoperability; and architectural - could do the trick. The smart modular machine with plug 'n' play simplicity for Lego block like assembly is no more a mere concept.

So back to the question of hype vs reality, Dr Zuehlke feels that Industry 4.0 will pass through the Gartner Hype-Cycle and pass the 'trough of disappointment' to enter the 'plateau of productivity'. The situation is akin to the age old chicken & egg story - what came first. So while the manufacturers are wondering 'who will buy smart components' and 'what is the customer demand', there are users asking 'where we can buy smart components' and 'where is the market'! A visit to the Hannover Messe could perhaps solve the puzzle!

The so-called smart refrigerator failed as a product because to the consumers it was not a necessity, had a high price-tag and was mostly viewed as solving a very minor problem. It is for diametrically opposite reasons the SmartFactory is likely to end up the winner: it is increasingly being viewed as a necessity in large parts of the world; the cost of implementation would be affordable in terms of payback; and above all the problems tackled would be significant enough to merit large scale implementation. Above all, with smart devices like phones, homes and cars already a reality, the smart factory is now just a matter of when, not if.

(with inputs from participating companies and www.hannovermesse.de, the website of the show)

Project "FlexiMon": Autonomous Manufacturing Modules

There's a lot of talk about the fourth industrial revolution in which machines and systems autonomously furnish information about their spare capacity and maintenance status, for example. But how can these technologies be designed from the outset so that they not only assist manufacturing staff in performing their work, but are also viewed by the latter as an asset?

HARTING Technology Group is currently exploring this research topic - among others - in the joint project dubbed "FlexiMon - Flexible Assembly Concept, which employs autonomous mechatronic manufacturing components. The project is part of the leading-edge cluster "It's OWL", which is being carried out as part of the "Leading-edge Cluster Competition" of the Federal Ministry of Education and Research (BMBF) within the framework of the High-Tech Strategy 2020 for Germany.

The launch point is the development of a modular production platform, which will be unveiled at the Hannover Messe 2014 trade fair and will feature - for the first time - the interplay of several production islands. The core of this platform is made up of configurable autonomous manufacturing modules equipped with "Plug n Produce" capabilities, autonomous control and a central, modular-independent man-machine interface.

HARTING Technology Group will use the Hannover trade fair to premiere three modules which handle the processes of screwing, stamping and inspecting. It is essential that these modules be adaptable during the production process so that, e.g., changes in a work plan for the manufacture of a product can be directly implemented at the production level with no additional intervention.

ZF-Duoplan for Machine Tools

ZF Industrial Technology is presenting at the Hanover Fair 2014 for the first time, its Industrial Technology Division. ZF's focal points are electronic and industrial solutions, E-mobility, system expertise, innovative products and development expertise. One of the exhibits is the ZF-Duoplan manual transmission.

Today, a machine tool must be universally applicable in order to process different materials. The two-speed ZF-Duoplan manual transmissions live up to these demands. High cutting speeds are needed for soft materials and major cutting forces for hard materials.

This level of flexibility can be obtained through the application of a shiftable transmission. On the one hand, the high speeds of the drive motor in the direct gear (1:1) are maintained and on the other hand, the motor's drive torque is multiplied via the ratio (e.g. i = 4.00) while the speed is respectively reduced.

The high-speed model range is used for higher speeds of up to 18,000 rpm; it is characterized by particularly smooth running and lowest possible temperature development. The latest development of the Duoplan model range is the hollow shaft drive.

This product owes its special feature to the innovative construction for which a patent was filed: The extremely compact planetary gearset is only active when it is really required. For high speeds in direct gear (transmission ratio 1:1), it stays decoupled, so that the rotary masses are significantly reduced.

High Voltage Electrode Boiler

Parat Halvorsen AS (Hall 27, Stand G33) has been making boilers since 1920. The electrode boiler has been designed and developed by its in-house engineers and manufactured at the company's workshop in Norway for more than 20 years.

Parat has delivered more than 7000 boilers to the Norwegian market alone, and is today the largest supplier of boiler systems in Norway. Increasing power generation from wind and solar systems have created a demand for fast frequency regulation of the electrical power grids. The Parat electrode boiler can be used for primary regulation with less than 30 seconds response time from minimum to full load.

Converting electrical power to heat makes it possible to accumulate renewable energy in periods of overproduction. Parat's partner AS:SCAN in Denmark has installed more than 7 electrode boilers in the Danish grid

Superconductors: Unique Potential for Automation Technology

Festo is carrying out research on superconductor technology for automation and will show three new application concepts at the Hannover Fair.

Superconductors have fascinating properties: when cooled to a certain temperature, they not only lose their electrical resistance but can also "freeze" the field of a permanent magnet positioned nearby and thus hold the magnet in position at a constant distance. The resulting stable air gap allows the contact-free, frictionless positioning and moving of objects without the need for control technology. For several years, Festo has been carrying out research into the advantages of superconductor technology for automation; the company is demonstrating three new, unique application concepts at the 2014 Hannover Fair.

With the SupraShuttle, Festo is demonstrating the movement of a levitating object in all directions and, for the first time, the handling of the superconductor element itself: the cryostat with the superconducting material is transferred from one electric axis system to another. The exhibit also shows how easily hovering objects can be introduced into a hermetically sealed space and moved within it. This feature would be useful, for example, for applications involving work with gases or in a vacuum.

Software Protection & Piracy

When companies like Sony, Kodak, Motorola and Siemens think of software security and DRM (Digital Rights Management) for documents and media, they think of Wibu-Systems AG (Hall 8, Booth D05). The lead theme chosen for this year is "Integrated Industry - NEXT STEPS" which reflects not just the urgency created by the advent of Industry 4.0 and the recent NSA surveillance scandal, but also the need to outline policies that protect both citizens and companies.

Wibu-Systems is definitely promoting this pragmatic approach and having its voice heard through industry associations as well as its own vision; the main concepts have resulted in a number of guidelines and best practices for manufacturers. European priorities are set on IT security and privacy at a level higher than ever before. By securing software and protecting the IP on the one hand, and by multiplying license schemes and facilitating their integration with existing networked and cloud infrastructures, we support ISVs and OEMs to maximize their software monetization models and ultimately we stimulate a fair economy system.

Automated Parking System from Bavaria

A whole new way to park cars will be shown serva transport systems GmbH (Hall 17, Booth F58) - an idea that revolutionised the transport of cars and parking in. The Bavarian company will be located on the "Red Carpet" which features the highlights of Industrial Automation.

In the serva automated parking system, a patented robotic system takes over the transportation and parking of cars, making it fast, easy and safe. This is ideal for car storage in the automobile industry and parking garages. The three founding partners, Rupert Koch, Cary Bellaflor, and Leopold Meirer developed this very special system under the motto "We park for you!" with early investment provided by the entrepreneurial family, Meltl, from Bavaria. The system has been ready to go since 2013. In April 2014, the automated system will be at D?sseldorf International Airport available everyday for airport customers. Further projects are already being planned such as an interim car storage facility for the automotive industry, a vintage car storage facility, and a facility for towed cars.

The system at the Hannover Fair will demonstrate how the automated parking works: the driver drives his car into a transfer station and the rest of the park-process is performed by robotically. The highly flexible automated guided vehicle (AGV) adapts automatically to the dimensions of each vehicle and brings it safely to its destination. Since the AGV's do not require rails, they are able to take individual routes and also maneuver in tight spaces. Car storage and parking garages can take on dynamic shapes.

Innovative Composite Drive Shafts in Highly Integrated Lightweight Design

The Institute of Lightweight Engineering and Polymer Technology (ILK) at the Technische Universit?t Dresden has developed a novel highly integrated lightweight design for composite dive shafts and associated methods for cost-efficient manufacturing within the support programme "Validierung des Innovationspotenzials wissen-schaftlicher Forschung (VIP)" of the Federal Ministry of Education and Research.

The Institute of Lightweight Engineering and Polymer Technology (ILK) at the Technische Universit?t Dresden has developed a novel highly integrated lightweight design for composite dive shafts and associated methods for cost-efficient manufacturing within the support programme "Validierung des Innovationspotenzials wissen-schaftlicher Forschung (VIP)" of the Federal Ministry of Education and Research.

In contrast to conventional drive shafts in multi-material-design one yoke of the cardan joint and part of the length compensation have been integrated into the composite structure. This integration of functional components allows the realization of new lightweight potentials.

A highly stressed drive shaft for railway applications with a maximum torque of 32 kNm served as an exemplary reference for the development and technological realization of a generic ultra-lightweight drive shaft. The mass of the experimentally tested ultra-lightweight drive shaft is about 50 % lower compared to the metallic reference drive shaft.

The composite drive shaft will be presented at the Hannover Messe at Hall 6, Booth D38.

Seamless E-Vehicle/Smart Grid Connectivity Through Intelligent Communication

To prevent e-vehicles from overloading power grids while charging, seamless connectivity is required. To help address this issue, Fraunhofer ESK is developing underlying communication methods for a uniform energy management system. At the Hannover Trade Fair (Hall 13, Booth C10), ESK researchers will be demonstrating how the charging station serves as an interoperable node between the e-vehicle and the network control centre using the ISO/IEC 15118 and IEC 61850 standards. Having already implemented both communication interfaces, ESK engineers can now illustrate how the concept works in practice. With its solution, the institute helps charging station and e-vehicle manufacturers and grid operators to implement the communication standards and test their products for standards compliance.

Whether vehicle authentication, automatic time-delayed charging or dynamic billing models - digital communication before, during and after charging is essential not only for the charging process. It also allows charging station operators to offer customers a wide range of value-added and convenience services. This also requires complex, EUwide communication technologies. This requirement, which is also being demanded by the EU, led to the creation of the ISO/IEC 15118 standard. "Our experience has shown that charging station manufacturers are still shying away from the standard because the implementation is too complex," explains Dr Erik Oswald from Fraunhofer ESK in Munich. "For this reason, we developed a reference installation that significantly streamlines the implementation."

Related Products

Infrared Thermometer

Nunes Instruments offers a wide range of infrared

thermometer.

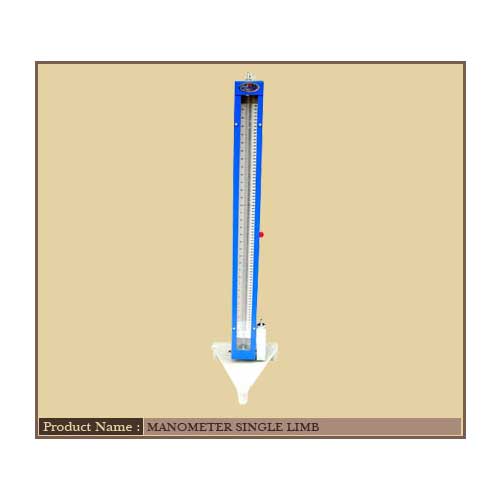

Manometer Single Limb

Zoom Instruments Manufacturing Company

manufacturers manometer single limb.

Cp 116 - Atmospheric Pressure Sensor

Kimo Electronic Pvt Ltd offers a wide range of CP

116- atmospheric pressure sensor.