Schedule a Call Back

Future trends in welding: Weld Eye

Technical Articles

Technical Articles- Jan 01,17

Rashmi Ranjan Mohapatra, Managing Director, Kemppi India, elaborates on future trends in welding with reference to WeldEeye – welding management software.

The Internet of Things or IoT is the internetworking of physical devices, vehicles (also referred to as ‘connected devices’ and ‘smart devices’), buildings and other items –embedded with electronics, software, sensors, actuators, and network connectivity that enable these objects to collect and exchange data. In 2013 the Global Standards Initiative on Internet of Things (IoT-GSI) defined the IoT as ‘the infrastructure of the information society’. The IoT allows objects to be sensed and/or controlled remotely across existing network infrastructure, creating opportunities for more direct integration of the physical world into computer-based systems, and resulting in improved efficiency, accuracy and economic benefit. When IoT is augmented with sensors and actuators, the technology becomes an instance of the more general class of cyber-physical systems, which also encompasses technologies such as smart grids, smart homes, intelligent transportation and smart cities. Each thing is uniquely identifiable through its embedded computing system but is able to interoperate within the existing Internet infrastructure. Experts estimate that the IoT will consist of almost 50 billion objects by 2020.

Typically, IoT is expected to offer advanced connectivity of devices, systems, and services that goes beyond machine-to-machine (M2M) communications and covers a variety of protocols, domains, and applications. The interconnection of these embedded devices (including smart objects), is expected to usher in automation in nearly all

fields, while also enabling advanced applications like a smart grid, and expanding to the areas such as smart cities.

The welding industry is no different:

Today 80% of the welding machine is electronic

The size of the market is US $ 9724 million, and

50 billion devices to be connected by 2020 (as estimated above).

The internet changed the way of working by connecting all the PCs of the world – as a matter of fact, Kemppi created the “Internet of Welding.”

With each passing minute, thousands of welds are welded all over the world at an increasing pace in even larger and more complex projects. Each weld is integral to the quality, and thus safety of the construction, and everyone close to it. All in all, welding is a big responsibility – and you are never far from a weld.

In today’s world, the demands of construction have grown to a new level with bigger projects, tighter schedules, and stricter quality standards. The foundation of all quality welding lies in Welding Procedure Specifications (WPS). How do you observe WPS compliance today, especially in manual welding work? WeldEye offers a convenient and accurate way of ensuring that all welding is done by qualified welders according to the WPSs. Automated digital data collection from the shop floor enables real-time quality control, making each weld traceable down to every meaningful detail. In addition, WeldEye provides verified quality documentation. Not only will you be able to convince your customers about the level of quality and safety of your project, but maintain peace-of-mind for yourself as well.

WeldEye is a universal solution to manage welding production. A balanced combination of software, hardware and cloud service, WeldEye creates value through insight: Insight into WPS compliant welding quality, production progress, personnel qualifications and much more.

Driving value creation

Knowing your welds is key, but knowing only takes you half way. Systemising your knowledge turns it into insight. Analysing and documenting your insight creates value. WeldEye is built for this exact purpose – to create value for everyone involved in and affected by welding.

Simplification

WeldEye simplifies your welding documentation process and cuts overhead costs.

Control

WeldEye offers full traceability and documentation from start to finish, making sure you are always on top of your welding projects.

Knowledge-driven efficiency

WeldEye boosts your efficiency by reducing the need for repair work. With more information available you can make better and quicker decisions.

Universal solution

WeldEye fits all welding equipment brands, is available globally and in multiple languages. It can be easily integrated into existing IT solutions, or accessed through cloud-based solution.

Future-proof technology

WeldEye is built on cutting edge technology and IT security, and is automatically updated when new standards are introduced.

Benefits:

Have total control over welding engineering, production, and testing from project start to finish

Decrease the time spent on manual paperwork with automated welding data collection in real time

Improve resource management with a complete overview of production status available at all times

Simple and efficient solution for welding procedure, and welder, operator and NDT personnel qualification management

Constant monitoring of WPS compliance with 100 % process traceability down to each weld

Cloud service enables global multi-site quality control and production performance analysis

Accelerate project delivery from weeks to minutes with as-built documentation

Support for AWS, ASME, EN, and ISO standards with pre-defined layouts, and

Universal connectivity to any manufacturer’s welding equipment.

Key applications: building steel frames, oil rigs, pressure vessels and boilers, refineries, etc.

Related Stories

Mahindra unveils EV manufacturing & battery assembly facility in Maharashtra

Mahindra has allocated Rs 45 billion out of the total Rs 160 billion planned in the F22–F27 investment cycle— which includes powertrain development, two product top hats including software & tec..

Read more

Jupiter International to invest Rs 65 billion in capacity expansion

Additionally, by fully integrating these processes, Jupiter International aims to establish a robust and seamless supply chain that spans every stage of solar manufacturing.

Read more

Chakr Innovation pioneers clean air solutions with RECD and aluminium-air tech

The Chakr Shield, India’s first Type Approved Retrofit Emission Control Device (RECD), sets itself apart by reducing particulate matter emissions by up to 90%, ensuring compliance with stringent e..

Read moreRelated Products

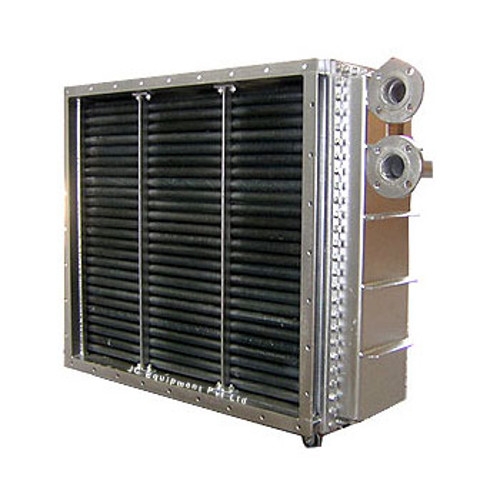

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Ceramic Reinforced Grinding Wheels

Rüggeberg GmbH & Co KG,

PFERD-Werkzeuge, has launched new reinforced grinding wheels with ceramic oxide

grain.

Potential Transformers Outdoor Type

Ereva Transformers & Switchgear is a

manufacturer and trader of supreme quality potential transformers.