Schedule a Call Back

Erdrill New, Revolutionary Feed Technology for Pneumatic Drilling and Carriage Units

Technical Articles

Technical Articles- Sep 30,11

Suhner's new feed technology for pneumatic drilling and carriage units allows electronic control of the pneumatic feed paths and speeds

Suhner has unveiled its new feed technology for its pneumatic drilling and carriage units. This innovative system allows the electronic control of the pneumatic feed paths and speeds. The company therefore offers an extremely low cost alternative to CNC technology. The heart of this new feed system is the so called Rhedamp damping cylinder.

The electrorheological fluid it contains is RheOil, consisting of a carrier liquid and polarising particles of polyurethane. When an electric field is applied, RheOil becomes highly viscous to almost solid within just a few milliseconds. The higher the voltage applied, the more tightly the particles "hold" together. Viscosity ranges from a minimum value resembling milk to the higher strengths, e.g., of a pencil eraser. The medium can be changed to any one of these viscosities within milliseconds, any number of times and free of wear. The effect does not deteriorate.

Conventional feed systems feature a hydraulic cushioning cylinder that must be used to configure the pneumatic drilling and carriage units. This involves great effort and sensitivity for the rapid and working traverse paths and speed. Only one rapid traverse and working speed can be set over the whole stroke.

Electrorheology allows the speed to be changed at any point over the cylinder's advance and return strokes. The standard pneumatic drilling and carriage units can therefore be used for new machining cycles and therefore new applications. Now other cycles are possible as standard in addition to the normal drilling cycle "rapid traverse advance - working traverse - rapid traverse return":

Electrorheology allows the speed to be changed at any point over the cylinder's advance and return strokes. The standard pneumatic drilling and carriage units can therefore be used for new machining cycles and therefore new applications. Now other cycles are possible as standard in addition to the normal drilling cycle "rapid traverse advance - working traverse - rapid traverse return":

• Chip removal (peck drilling)

• Intermittent feed (chip breakage)

• Jump function (two walled drilling of pipes)

• Various feed speeds e.g. for shouldered holes (countersinking), and

• Reverse countersinking.

All of these functions require a measuring system.

This takes the form of a linear potentiometer with a depth and positional precision of 0.1 mm. The ERdrill system also includes a small electronic drive and feed controller that does not require any programming knowledge. Solely one of the above working cycles is selected on the controller's display. Then the paths are entered in mm and the speeds in mm/min.

The ERdrill system is an interesting solution above all for small batch production with frequent changes of products and therefore constant adjustments to the feed paths and speeds. (Suhner India Private Limited, Bangalore. Tel: 080-27831108. Fax: 91-80 27831109. Email: automation.in@suhner.com)

Related Products

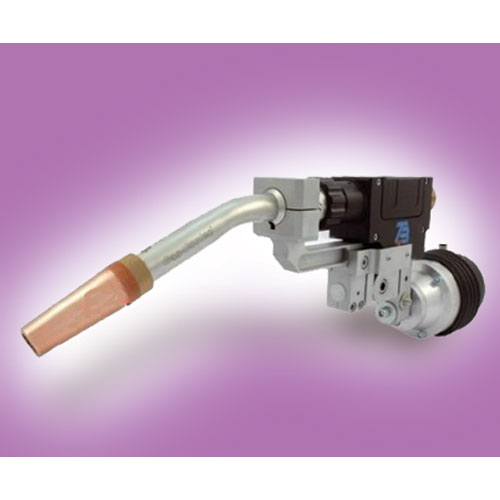

Welding Automation

Drupe Engineering Private Limited is offering a wide range of welding automation.

Robo Mig Tbi Robot Welding Torches

Mehta Sanghvi

& Company manufactures Robo MIG TBI robot welding torches.

Heavy Duty Goliath Crane

Ganesh Engineering Co manufactures and supplies a broad array of heavy-duty goliath crane.