Schedule a Call Back

Energy Efficiency as a Strategic Priority for Indian Manufacturing

Articles

Articles- Dec 18,25

India’s manufacturing sector sits at the centre of the

country’s economic ambitions. It contributes more than 16 per cent to the

national GDP and supports over 27 million workers across formal and informal

units. Its scale reaches into every major industry, from textiles and chemicals

to steel and machinery. This breadth has made manufacturing a steady engine of

economic activity and innovation. The sector is expected to contribute 25 per

cent to the GDP, and by 2030, its share in the overall goods exports will reach

one trillion dollars.

This growth story, however, comes with responsibility. As

manufacturing output rises, so does energy use, manufacturing already accounts

for nearly 27 per cent of India’s commercial energy consumption. When viewed

within the larger industrial segment, the share climbs to around 42 per cent of

the country’s total electricity use. The pressure will grow as more plants

expand production lines, add new machinery, and move towards more advanced

digital operations. Even with the steady increase in renewable capacity, most

electricity still comes from coal. This creates both financial and

environmental strain, making energy conservation more than a moral choice. It

has become a strategic requirement.

Why energy efficiency

has become a strategic priority

Over the past decade, manufacturing processes have become

more energy intensive. Automated lines, precision machining, and continuous

processing improve product quality, yet they also draw more power. Reduced

electricity bills could bring down energy-related costs by 10 to 15 per cent.

For businesses working with tight operating margins, this difference matters.

In some industries, electricity alone accounts for 20 to 30 per cent of total

production costs. These include metals, cement, chemicals, and heavy engineering.

A modest reduction in energy expenses can alter financial performance. If the

electricity cost is cut by just 10 per cent, EBITDA margins can increase by 40

to 100 basis points, depending on the sector.

Alongside cost concerns, energy efficiency now plays a

direct role in global competitiveness. Exporters in automotive, steel, and

aluminium are being assessed on the carbon footprint of their products. Global

regulations, including the European Union’s Carbon Border Adjustment Mechanism

and similar trade-linked norms, are strengthening this requirement. In this

environment, each unit of energy saved carries a dual reward. It lowers

production costs and improves compliance with international standards. Energy

management has therefore shifted from being a support activity to a core

component of export readiness. For Indian manufacturers, treating efficiency as

a strategic priority is vital for cost control, regulatory adherence, and

sustainable growth.

Energy efficiency

equipment a driver of stronger performance

Energy-efficient systems help plants produce more with the

same amount of power, sometimes even less. In process industries such as pulp

and paper, pharmaceuticals, and food and beverage, rotating equipment is among

the most energy-intensive assets. Pumps, compressors, agitators, and mixers

operate for long hours, moving liquids, chemicals, and slurries through

critical production processes. Small improvements in the efficiency of these

machines can translate into meaningful reductions in energy consumption,

helping plants manage costs without compromising throughput. Optimising the

performance of these assets ensures that electrical energy is converted into

mechanical work as effectively as possible, directly supporting lower overall

energy demand.

Mechanical seals and seal support systems play a crucial

role in maintaining the efficiency of rotating equipment. Properly designed

seals reduce friction, prevent leakage, and allow pumps and compressors to

operate closer to their ideal efficiency curves. Even marginal improvements in

sealing performance can significantly decrease the energy required to maintain

pressure and flow. In continuous operations, such as paper manufacturing or

pharmaceutical processing, these gains scale rapidly, offering measurable

benefits across entire production lines and contributing to more stable and

predictable output.

Alongside individual equipment improvements, system-level

enhancements also support energy savings. Optimised layouts, reduced

recirculation losses, and correct sizing of pumps and compressors ensure that

energy is not wasted in unnecessary circulation or overcapacity. When combined

with advanced equipment that is designed for efficiency and reliability, these

measures allow plants to meet rising production demands while keeping energy

consumption under control. The result is a more cost-effective operation, a

predictable energy profile, and a stronger foundation for sustainable growth.

Efficiency needs

insight, not just equipment

Efficiency gains from modern rotating equipment can be

significantly enhanced through smart monitoring and analytics. Real-time

sensors track energy consumption, vibration, temperature, and pressure across

pumps, compressors, agitators, and mixers, providing detailed insights into

operational performance. This visibility enables plant teams to balance loads,

optimise processes proactively, and uncover inefficiencies that might otherwise

go unnoticed. Even minor misalignment or underperformance in critical equipment

can increase electricity consumption and introduce variability, making it more

difficult to maintain consistent production and predictable energy usage.

Advanced analytics platforms build on these insights by

consolidating operational data and highlighting trends or anomalies. Operators

can pinpoint where energy use deviates from expected patterns and implement

targeted adjustments before inefficiencies escalate. Over time, these small,

incremental improvements accumulate across the plant, creating a more

predictable energy profile and reducing overall energy intensity. The results

are tangible as plants lower operating costs, improve resource utilisation, and

make measurable progress toward sustainability goals. Teams can even track

performance against internal benchmarks and broader environmental standards,

ensuring energy efficiency becomes actionable and visible.

The adoption of smart monitoring tools also fosters a

proactive energy management culture. Plant managers gain a clear understanding

of how operational decisions impact energy use, enabling smarter scheduling and

load distribution. Operators develop real-time awareness of the effects of

their actions, embedding efficiency into daily routines rather than treating it

as an occasional initiative. Applying these insights across rotating equipment

strengthens overall plant performance, reduces energy waste, and improves

operational resilience. These operational insights and efficiency gains not

only strengthen plant performance but also position manufacturers to respond

effectively to evolving policy frameworks and incentive programmes aimed at

promoting energy conservation.

Policies and trends

accelerating the shift

Government programmes further support these efficiency

efforts, guiding industry adoption of structured energy conservation practices.

The Perform Achieve and Trade scheme remains central to this agenda. Recent

updates show that PAT is now more closely aligned with the upcoming Carbon

Credit Trading Scheme, which has already notified emission intensity targets

across nine major sectors. This marks a shift from voluntary improvements to

structured, compliance-led reductions in energy use. Because it links performance

with measurable requirements, the policy framework encourages companies to

treat efficiency as a long-term discipline.

Several states have added their own incentives. These

include capital subsidies, interest support for efficient equipment, and

preferential tariffs for facilities that meet certified energy standards.

Support for rooftop solar installations and building upgrades has also

strengthened. These moves make the shift to efficient systems more accessible

for both large and mid-sized industries.

Market dynamics are reinforcing this momentum. Variable

Frequency Drives, efficient motors, and upgraded boilers have become more

affordable. Plants often recover their investment in VFDs within one to two

years. Lighting upgrades, particularly LEDs, deliver payback periods of less

than a year in facilities with long operating hours. As prices decline and

performance improves, businesses view energy conservation as part of routine

operations rather than a peripheral sustainability project.

Conclusion

Energy efficiency in manufacturing is becoming a cornerstone

of future-ready operations. Plants that integrate reliable equipment with

actionable data insights can optimise processes, maintain consistent

performance, and ensure energy is used effectively across critical systems.

This capability supports smoother production planning; better load

distribution, and greater operational reliability, helping manufacturers scale

output without increasing energy strain.

Looking ahead, these practices will strengthen energy security and reduce demand pressures on the grid while enhancing the global competitiveness of Indian manufacturing. Embedding efficiency into everyday operations positions energy management as a strategic enabler, delivering cost savings, predictable performance, and measurable progress toward sustainability targets. Manufacturers that continue to adopt smarter processes and optimise energy use will be better equipped to meet evolving production needs and environmental expectations, securing both economic and operational resilience.

About the author:

Satish Ingavale is an industry leader with extensive

experience in engineering and industrial solutions, currently serving as

Managing Director of John Crane India. Beyond his MD role, Satish holds senior

leadership positions across related engineering and services companies,

including as Additional Director at Smiths India Services and Director at

Seebach Filter Solutions India.

Related Stories

Why is Workmen Compensation Insurance Essential for Both Employers and Employees?

Workplace risks are an unavoidable reality across India’s diverse industries like construction, manufacturing, logistics, housekeeping, hospitality and more. Even with strong safety protocols, acc..

Read more

3D Printing Strengthens the Foundations of Smart Manufacturing

The global 3D printing market was estimated at $30.55 billion in 2025 and is projected to reach $168.93 billion by 2033, growing at a compound annual growth rate of 23.9 per cent from 2026 to 2033.

Read more

IMTEX Forming 2026: Charting the Next Chapter of India’s Metal Forming Ecosystem

IMTEX Forming 2026, Asia’s largest metal forming and manufacturing technology exhibition, is set to return to Bengaluru from 21–25 January 2026.

Read moreRelated Products

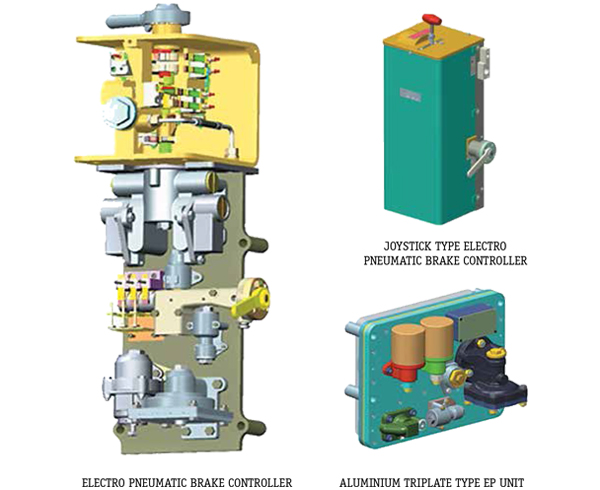

Electro - Pneumatic Brake System for Emu

Escorts Kubota Limited offers a wide range of electro - pneumatic brake system for EMU.

Indef Powered Crane Kit

Hercules Hoists Ltd offers a wide range of Indef powered crane kit.

Jib Crane

DC Hoist & Instruments Pvt Ltd offers a wide range of Jib crane.