Schedule a Call Back

Empire Cables: Connecting Trust & Reliability

Technical Articles

Technical Articles- Jan 04,16

Empire Cables is keeping pace with the latest trends in technological innovations in the field.

E mpire Cable Industries Pvt Ltd has unfolded the new dimensions of progress and development by taking the initiatives to build a forte of intellectual prowess and zero-defect quality to shield the imperative expectations of the cable and wire industry. The company is one of India’s youngest independent wire and cable manufacturers, with a track record of over a decade of service to the electrical and automobile industries. It is among the leading manufacturers of wires and cables in northern India with the largest dealer and distributor network all over the country. It manufactures a complete range of low tension (1100 V grade) cables.

The ISO 9001-2000 certified company caters to the diversified needs of customers, thus providing them with a comprehensive solution of wires and cables such as PVC/PE insulated wires, LT-PVC/XLPE power control, instrumentation cables, flexible and house wires.

Manufacturing of Cables

The cables are manufactured with aluminium and copper conductors and polymer insulation. Essentially cables comprise of conductors, insulation, inner sheath, armour and outer sheath. The conductors are solid/stranded circular/shaped, aluminium or copper conductors, with stranding making the cables flexible and easy to handle.

Compaction is provided to all stranded conductor constructions as under:

Circular conductor: With one wire in the centre the conductor contains 6, 12, 18, 24, 30 or more wire layers in either unilay or opposite helical directions. The conductor is compacted

Shaped conductor: In all multicore cables from 16 sq.mm size, conductors are “shaped”. However 6 and 10 sq.mm conductors can be solid/stranded circular

Segmental conductor: As a special case cables of 1600 sq.mm are made up of segmental conductors.

Empire copper conductor cables are of the same construction that of cables with aluminium conductor except for high tensile strength, superior conductivity, better flexibility and ease of jointing. Copper cables are used in control, instrumentation, winding, submarine, mining and ship wiring, applications, among other. All conductors conform to national and international specifications – National specifications – IS: 8130, and International specifications – IEC: 60228/BS: 6360.

The cables are designed and manufactured with polymer dielectrics to bear thermal and thermo mechanical stresses safely at continuous normal and short circuit temperature conditions. The cables are available with both thermoplastic and thermo setting insulations:

* PVC cables – Thermoplastic dielectric, and

* XLPE cables – Thermo setting dielectric.

PVC cables use PVC compounds that take care of overload and short current with both course and fine protection systems. XLPE cables use XLPE compound with anti-oxidant stablisers and traces of aromatic polynuclear hydrocarbon. Thus improving electrical treeing characteristics and mechanical strength of insulation.

The range of cables includes: Power and control cables; HT and LT cables; multi-core flexible wires; submersible cables; coaxial cables; tele-communication cables; house wiring and industrial cables; PTFE coated wires and cables; TRS/TRS braided cables; and special type of cables.

Armouring: mechanical protection to the cable is provided with armouring. Empire single core cables are armoured with aluminium or aluminium wire/strips, thus avoiding magnetic hysteresis losses on AC system.

Multicore cables are provided with galvanised steel wire/strips. The cables are provided with galvanised wire armouring, where cables are to run vertically and are subject to stress.

Empire mining cables are armoured with double steel wire and tinned copper wires, so as to provide conductivity of armour more than 75% of main conductor of cable.

Empire cables armour wire/strips are of low resistivity material and meet the requirements of IS: 3975. The company also offers fire retardant cables.

Final Testing

Each Empire Cable is tested for all applicable routine tests. From a lot of cables one cable of each type is tested for Type Tests, as per relevant specifications. The company conducts testing of cables for acceptance test as per specifications. This is carried out as per Empire work standards for testing, besides applicable standards.

(Empire Cable Industries Pvt Ltd, Delhi. Tel: 011-23868832, 23867957, 55351123. Fax: 91-11-23861610. Email: sales@empirecables.com)

Related Stories

Government unlikely to ease restrictions on Chinese telecom vendors

Officials confirmed that while companies like ZTE can manufacture products in India, they must adhere to the government's "trusted sources" policy, which prohibits the deployment of non-trusted equi..

Read more

Adani Green and TotalEnergies to form $444 million joint venture

Adani Green Energy stated that both companies will equally share the equity of the joint venture, named ARE64L, with each holding a 50% stake.

Read more

SBI to adopt cash-flow based lending for MSME loans up to Rs 50 million

SBI is collaborating with multilateral development banks and large multinational banks to address these challenges.

Read moreRelated Products

Win Series Interface Relay Modules

Werner Electric Private Limited offers a wide range of WIN Series interface relay modules.

Centric Gripper

Schunk intec india offers a wide range of centric grippers-dpz-plus

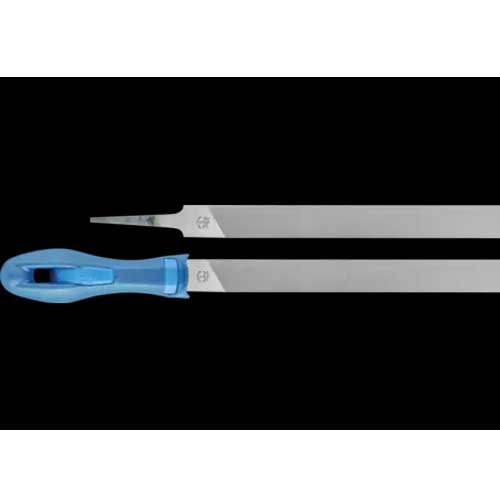

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.