Schedule a Call Back

Dust collectors for environment friendly manufacturing

Technical Articles

Technical Articles- Jan 06,15

If you think industrial work and air pollution go hand-in-hand, think again! The use and manufacture of machines does not always mean adverse environmental consequences. Eco-friendly thinking is not just for environmental activists anymore. Its about time everyone stood up and took notice of the rising threat of global warming and the need for an environment friendly sustainable manufacturing set-up where growth is inclusive with environmental protection.

Prem Brothers, a CE certified organisation, is known for its range of grinding, polishing machines and dust collectors since 1959, without compromising on environmental concerns. Manufactured under the brand name "Power Master", the dust collectors are specially designed for collection of dry ferrous dust, generated during grinding process.

While grinding on any type of grinding machine (say a bench grinder) some metal (or material from the grinding wheel) is removed from the job in the shape of fine dust. This dust is an environmental problem or a health problem for the operator, and should, therefore, be entrapped at the source itself, before it spreads or becomes air-borne. Power Master manufactures a wide range of dust collector systems, which enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities.

Features such as low noise, low power consumption, and high filtering efficiency make them convenient for use. These dust collectors use fabric filters. Commonly known as baghouses, fabric collectors use filtration to separate dust particulates from dusty gases. They are efficient and cost effective and can achieve high collection efficiency for very fine particulates. Dust-laden gases enter the baghouse and pass through fabric bags that act as filters. Cotton filtering sleeves provide security against inflammation.

In addition, suction inlet mounted on adjustable arm and water dust separator for aluminium dust are available as optional accessory.

Power Master dust collectors provide a suction capacity of 1, 2, 3,or 5 HP as required and are designed to run on 3-phase, with CFM ranging from 190 to 2500. Each dust collector is provided with a manual shaker mechanism. On-off starter is available on request.

To reduce pollution in their own manufacturing facility, Prem Brothers has installed dust collectors for various applications on their machines such as surface grinding machine, tool grinders, lathe machine for cast iron components, milling machine, etc.

Pollution control is not an option but a necessity. With the shortage of labour, there are a large number of options available to work in non-polluting units. It is in the business interest to add pollution control devices such as dust collectors at the source of generation, to capture the hazardous fine dust particles, which pollute the environment, endangering the health of workers in the long run.

Keeping in mind specific applications, Power Master also manufactures dust collectors specifically for the collection of wood dust, fine dust, and for use with surface grinders.

Dust collector for wood dust is designed for the collection of wood dust, shavings, and other type of non-ferrous, light-weight dust particles. Dust collector for fine dust is designed for the collection of fine dust such as that generated while grinding brass. Dust collector with coolant combo for surface grinder combo design wherein dust collector used for collecting dust from dry grinding process and coolant arrangement for wet grinding can be used intermittently as required. An oil mist and dust collector is designed for the collection of oil mist along with grinding dust. Aesthetically designed in a compact size, these can be mounted on top of CNC machines or behind a grinding machine.

In addition to separate dust collectors, Power Master also manufactures bench grinders, belt grinders (both single head and double head) and polishing machines with built-in dust collectors, the first company to do so in India. These machines are specially designed for the purpose of controlling dust, and are mounted on a steel body with an in-built dust collector, making the machine compact and user friendly. The company also offers parts and accessories of dust collectors. Buff guards are available as per customer job requirement, with centre height 24", 36", or as required. Dust guards are also available for both single ended and double ended belt grinding machines, or as required. Dust collectors with multiple inlets are also available which can be connected with more than one polishing/grinding machine.

Taking this environment friendly initiative forward, Prem Brothers recently introduced their new range of environment friendly workstations or down draft tables. Recently, Prime Minister Narendra Modi stressed on using environment friendly techniques, while exhorting the industry sector to make India the manufacturing hub of the world. His 'zero effect, zero defect' remark emphasized on making products which have 'zero defect' so that they do not come back from the world market, and 'zero effect' so that manufacturing does not have an adverse effect on our environment.

These worktables are compact stations with built-in dust suction, filtration and dust collection arrangement. They draw contaminants away from the worker's breathing zone without hindering the worker's movement or productivity.

Power Master workstations are available in varied sizes and configurations, with varying degrees of control to suit specific job, filtration or space requirements. The basic design has a comfortable working height and incorporates a fan or blower powered to pull air and particulates away from the workstation area/operator, and down through cartridge filters. These workstations have built-in noise suppressor, light and power output, low power consumption and high filtering efficiency even for fine dusts.

These workstations are specially designed for the collection of fine particles generated from grinding, filing, sanding, welding or finishing process, where the job is kept on the table and the process is undertaken, using portable hand grinders, flexible shaft grinders, etc.

With the mounting pollution and consequent concern for environment protection, Power Master dust collectors, built-in dust collectors and environment friendly workstations are the requirements of today for pollution control. The company also offers environment friendly floor type grinding tables for use while sitting and working. These worktables are available with 1 or 2 suction ports as required and can be connected to a dust collector for collection and filtration of dust and other pollutants.

Prem Brothers, New Delhi. Tel: 011-28117456, 28117464. Telefax: 91-11-45595068. Email: powermaster59@gmail.com

Related Products

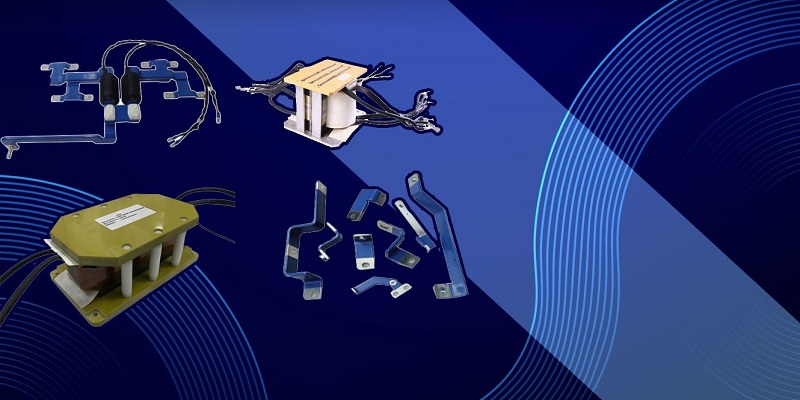

High Speed Tripping Relay Two Element Relay - Jrv 181x2

JVS Electronics Pvt Ltd offers a wide range of high speed Read more

Plenty of Motion Possibilities in a Compact Housing

B&R Industrial Automation offers a wide range of plen Read more

High Speeed Tripping Relay Three Element Relay

JVS Electronics Pvt Ltd offers a wide range of high speed tripping relay three element relay - JRV 181x3.