Schedule a Call Back

Defined edges in one-step operation

Technical Articles

Technical Articles- Dec 08,15

- FLORIAN POTTRICK

The new Edge Finish system from PFERD defines edges and radii in a one-step operation – comfort and use are impressive.

Defined edges are a ‘must’ in many areas of steel construction: Whether as preparation for the application of anti-corrosion coatings (e.g., in accordance with ISO 12944-3 or ISO 8501-3), or for the weld seam preparation (in accordance with ISO 9692-1), work on the edges of steel tools is becoming increasingly important.

Defined edges are a ‘must’ in many areas of steel construction: Whether as preparation for the application of anti-corrosion coatings (e.g., in accordance with ISO 12944-3 or ISO 8501-3), or for the weld seam preparation (in accordance with ISO 9692-1), work on the edges of steel tools is becoming increasingly important.

Numerous grinding and milling tools are commercially available to the user for work on edges: The selection is varied, from reinforced grinding wheels and flap discs to hand-held mounted burrs. However, all of these hand-held solutions have a problem: They do not create a defined edge or a precisely determined radius. Thus they cannot be used on any component where a defined edge or precise radius is required.

This is why, for a number of years, special solutions have been available for production of defined edges. PFERD has revisited the topic of ‘edge breaking and rounding’ and is now proposing a smarter, more efficient and comfortable-to-use solution in the form of the ‘Edge Finish system’.

The Edge Finish system consists of an angle grinder, a cutting insert holder and various sets of cutting inserts, specially designed, in terms of performance and handling, for work on edges and matched to the respective requirements: Chamfer or R3. The company also provides the appropriate guide bearing, as well as screw sets for cutting inserts.

The drive, an angle grinder modified for work on edges, has a power output of 1,750 W. It has a steplessly adjustable speed of between 2,750 and 11,000 RPM, according to the application. The digital electronics guarantee constant RPM. The machine also has overload protection and restart protection after voltage dips or power failures. To protect both the machine and its user, the grinder runs up to speed smoothly when turned on. The PFERD anti-vibration handle, the ‘Sensohandle’, on the ergonomically angled holder, provides optimal handling and reduces perceptible vibrations on the handle.

The cutting insert holders are mounted directly on the work spindle of the drive. PFERD provides two different cutting insert holders for the various 30° chamfer, 45° chamfer and R3 applications. The three cutting inserts can be mounted on each of these cutting insert holders. At the lower end of the cutting insert holder is a bearing, for cleanly guiding the tool along the edge of the workpiece.

The most remarkable characteristic of the Edge Finish system is the fact that the assembled and ready-for-use machine is so light and easy to handle, with a weight of just 4.4 kg. The guide plate and guide bearing on the cutting insert holder make positioning and adjustment on the workpiece easy and intuitive.

In use, it is clear how aggressively the cutting inserts get to work. Even when producing a 45° degree chamfer, the stock removal rate is impressive, allowing very high feed rates. The system thus remains under control at all times and is easy to guide; not least due to its ergonomically designed handle. Unlike other systems, the handle is not fastened at right angles on the head of the machine, but is precisely adapted to the typical posture of the operator via a high-quality, polished, stainless steel angled handle, making work with the system comparatively easy and fatigue-free.

The coated cutting inserts display a high wear resistance. This high quality and the resulting long tool life, in conjunction with the remarkable stock removal rates, significantly reduce process costs. The ergonomics, optimised through the low-vibration and well handling drive, protect the health of the worker.

PFERD provides the Edge Finish system for work on edges in two versions, each supplied in a transport case for the drive and accessories. All of the parts can also be ordered separately.

Work on edges has never been so simple, so fast, so economic and so ergonomic. In comparison to other existing products on the market, the PFERD Edge Finish system provides an economic, highly effective and above all practical solution for the high requirements for producing defined edges.

PFERD/Swit, Bangalore. Tel: 080-42187117. Mobile: 096202-08633. Fax: 91-80-42187118. Email: info@pferd.co.in

Related Stories

MSI and Syrma SGS to manufacture ‘Make in India’ laptops for Indian market

MSI and Syrma SGS are setting the stage for a phased approach to localise manufacturing for MSI in India through this alliance, starting with the assembly of laptops.

Read more

Mahindra unveils EV manufacturing & battery assembly facility in Maharashtra

Mahindra has allocated Rs 45 billion out of the total Rs 160 billion planned in the F22–F27 investment cycle— which includes powertrain development, two product top hats including software & tec..

Read more

Jupiter International to invest Rs 65 billion in capacity expansion

Additionally, by fully integrating these processes, Jupiter International aims to establish a robust and seamless supply chain that spans every stage of solar manufacturing.

Read moreRelated Products

Fieldpower Power Bus System

Weidmueller Electronics India offers FieldPower power bus system.

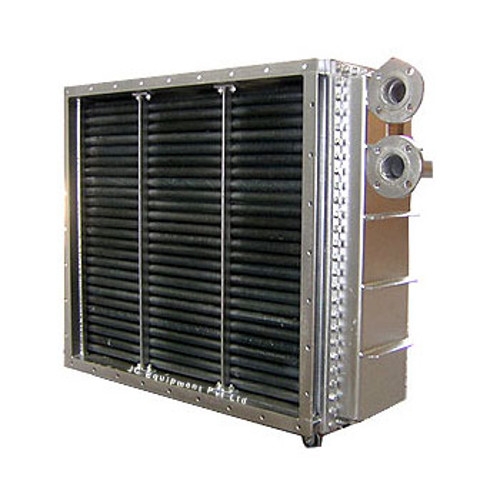

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Ceramic Reinforced Grinding Wheels

Rüggeberg GmbH & Co KG,

PFERD-Werkzeuge, has launched new reinforced grinding wheels with ceramic oxide

grain.