Schedule a Call Back

Danfoss

Technical Articles

Technical Articles- Apr 03,13

On the eve of ACREX India 2013, a dedicated event for the Air Conditioning, Refrigeration and allied Building Services segments, Danfoss Industries had organised a unique curtain raiser to engage the stakeholders from the user industries

Following the ACREX India theme of 'Dedicated to eco-friendly Environment', Danfoss - a global leader in energy-efficient solutions that save energy and costs, and reduce CO2 emissions - highlighted some of its new products for the air-conditioning segment. These include VZH - the 2nd generation of inverter scroll compressors for commercial applications; SH485 - Danfoss' innovative 40-tonne compressors for large chillers and rooftops; and LLZ - the new scroll compressor for LBP (low back pressure) refrigeration, which broadens the existing range for MBP (medium back pressure) applications.

"We are pleased with being associated with ACREX 2013. This is a unique platform to increase awareness and the importance of energy efficiency thereby enabling and building a sustainable future for India. The CO2 challenge is real and energy consumption will grow by 45% by the year 2030, therefore, the need for deploying CO2 abatement technologies is getting much stronger. We at Danfoss with our 'Solution ready' platform can significantly contribute to India's energy efficiency agenda. I really look forward to engaging with industry stalwarts on this exciting event," said P Ravichandran, President Danfoss India, commenting on the event.

While saving energy and reducing CO2 emissions is a global concern, in India, Danfoss has its focus on food security as well, given the fact that 40-45 per cent of food produce is wasted for want of effective storage and lack of cold chains, areas in which the company has the solutions, and in this particular case, the savings not only in energy but also in saving the wastage for food. Mr Rajesh Premchandran, Director, Refrigeration & Air-Conditioning, Danfoss Industries Pvt Ltd, in his presentation mentioned the various initiatives taken by the National Horticulture Board and Ministry of Food Processing Industries for developing the cold chain system in India for which there is no single solution given the diverse requirements of a country as large as India, besides the economical aspects of tailoring a system to suit the cost sensitive user community of small farmers and land holders.

Danfoss is also associated with the initiative for developing an integrated cold chain for bananas in Tamil Nadu, which happens to be the largest banana producing state in India. Rajesh, incidentally, has played a pivotal role in conceptualising India's first Cold Chain Centre at Chennai promoted by Danfoss as a one-stop destination for cold chain solutions. This state-of-the-art centre assists various stakeholders in relevant updates on new software and product catalogues. In addition, the centre also displays the complete range of key products like controls for ammonia/freon cold store systems, condensing units for dairy and cold chain applications, ADAP-KOOL? solutions for supermarkets; variable speed drives suitable for the refrigeration industry and much more. Two more Cold Chain Centres are planned, one each in Delhi and Pune, in the near future.

Danfoss has also helped a major customer in the food supply chain business to help achieve energy savings of 15-20% by central monitoring of its warehouse at Hyderabad. Arup Majumdar, Vice President, Marketing Strategy & Inverter Scroll, Danfoss Commercial Compressors, while presenting an overview of the new developments in compressors (see interview) said that energy saving of 30% is very much achievable with the new inverter scroll compressors (with drive) in commercial applications. He also mentioned the new Optyma Dairy, a compact, energy efficient solution for milk cooling tanks adopted by a major dairy in north India achieving a saving of 17-20%. With the cost of energy rising exponentially, the payback period for such energy saving products typically ranges from 18 months to 2 years.

In fact the VZH 2nd generation inverter scroll compressors mentioned at the beginning has received honourable mention in the cooling category during the 2013 AHR Expo Innovation Awards, judged by a panel of ASHRAE members, in December 2012 in the US. At the same ceremony the ADAP-KOOL? AK-PC 781 integrated rack controller was named the winner in the refrigeration category.

For a company that until recently was merely performing a sales and marketing operation in the country, Danfoss is now planning systematically to make India an engineering, R&D and manufacturing base for the Asian region, and has embarked on a 3-year plan, starting with state-of-the-art manufacturing facility at Oragadam near Chennai at an investment of Rs 500 crore for both R&D and manufacturing. In early 2012 it opened a new Psychrometric Test Lab for its Refrigeration & Air Conditioning (RC) division at Chennai. Later in September it inaugurated a reciprocating compressor development laboratory at Maraimalai Nagar, Chennai, which will primarily focused on re-designing of reciprocating compressors.

Between these two developments there were two more - opening of a filter drier factory and starting the Cold Chain Centre, mentioned earlier, at Chennai. Commenting on these developments, Mr Henrik Schurmann, Vice President of Danfoss Refrigeration and Air Conditioning Controls in India, said that the Oragadam facility would be housed in a Platinum rated building, to be completed by 2014. By then, the company will triple its total staff strength to 1200 from the existing 400.

Danfoss India, 100-per cent owned subsidiary of Danfoss Group, is a leader in mechanical and electronic components and solutions. The company serves a wide range of industries that rely on Danfoss products for their component and sub-system needs-state-of-art refrigeration, air conditioning components and controls, VLT? drives and a range of heating valves, controls and solutions for HVAC, district cooling and under floor heating applications. Add to this the Danfoss Industrial Controls Business Unit, which develops, manufactures and markets pressure and temperature controls, industrial valves and contactors and motor starters, and the customers get a truly one-stop-solution, much like a multi-layered cake, with energy saving as the tantalising icing on top!

| Mr Arup Majumdar, Vice President, Marketing Strategy & Inverter Scroll, Danfoss Commercial Compressors, was present in Mumbai during the event. Based in Lyon, France, Mr Majumdar is a member of the Danfoss global management team with over two decades of global experience in the HVAC/R industry. He spoke to Industrial Products Finder on the recent developments in the field of compressors. Excerpts: What is the range of compressors made by Danfoss? Danfoss manufactures fixed speed scrolls, variable speed solutions, reciprocating compressors and condensing units. These technologies are used in various applications in air-conditioning, refrigeration and heating. Danfoss Commercial Compressors is the leading provider of inverter scrolls with pre-qualified drives for commercial air-conditioning for buildings, malls, data centres, etc. The range covers 2.5TR - 200 TR in a single unit from small direct current hermetic compressors for mobile applications up to large centrifugal compressors for large commercial air conditioning. These also use various types of refrigerants. The company presently manufactures compressors at three locations in France, USA, and China. What is the significance of the Danfoss Turbocor range of compressors? The Turbocor range, manufactured by Danfoss Turbocor Compressors, in USA, was earlier a joint venture but is now completely under Danfoss, are high efficiency variable speed compressors in the capacity range of 60-200 tonnes per unit. These are used in very large commercial air-conditioning applications, in rooftops, malls, hotels, etc. These are variable speed compressors where the motor has an intelligent control system based on actual requirements, thus saving energy by running the compressor at appropriate speed based on actual cooling required at any given time. So for example, if a certain space is occupied by a small number of persons, the cooling required is less, whereas if a large number of people join them, more cooling would be required. Such variables as also the time of the day, actual temperature outside, etc., is used in the smart controls that determine the speed. What are the constraints in promotion of energy saving compressors in the commercial domain? One of the main constraints is the fact that while the Bureau of Energy Efficiency (BEE) has done a very good job with its star rating programme for domestic appliances like air conditioners and refrigerators, the same is not extended to the commercial segment. There is inherent resistance from consumers to buy energy efficient products because the initial cost is high, but this is actually offset by lower electricity bills where the payback is between 2.5 to 3 years in case of domestic appliances, whereas in commercial applications, payback can be down to 1? year. Cost apart, what could be the other reason? High star rating of an air-conditioner in such cases means the size gets bigger. Basically it is the size of the heat exchangers (made of copper and aluminium) that increases, making the unit bigger than conventional products. Compact is not always good, and in this case higher efficiency comes in a bigger size. What is the present position vis-?-vis the ideal refrigerant? This is an issue being debated endlessly with no consensus emerging as of now. While it is accepted by all that the early refrigerants were toxic and harmful, among the various new alternatives that have been developed over a period of time, there is no single perfect solution and hence the regulatory hurdles. Refrigerants are evaluated based on their corresponding global warming potential (GWP) and ozone depletion potential (ODP). But to cut through the jargon, one has to realise that finally there has to be some sort of trade-off, like for example, accepting a mildly inflammable product to achieve the right balance. But as mentioned, the consensus is elusive so far. So what began with the Montreal Protocol of 1987 has now reached a critical stage and it is time the consensus emerges soon for serious implementation to begin. |

Related Products

Win Series Interface Relay Modules

Werner Electric Private Limited offers a wide range of WIN Series interface relay modules.

Centric Gripper

Schunk intec india offers a wide range of centric grippers-dpz-plus

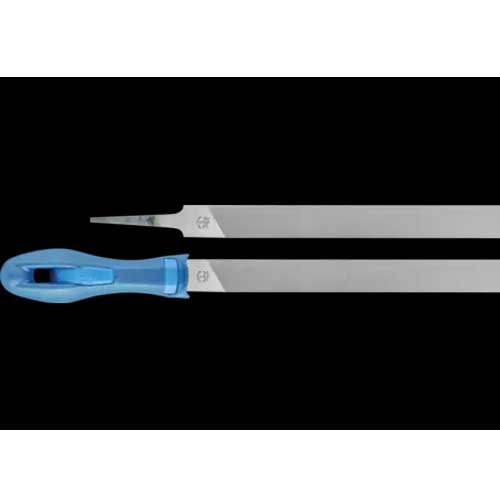

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.