Schedule a Call Back

Creep-feed Grinding

Technical Articles

Technical Articles- Mar 17,11

Creep-feed Grinding Machine with micro granite bed, a Cosmos Design Team innovation, is a fine example of state-of-the-art technology, a first in India

Creep-feed grinding represents the most revolutionary invention in the grinding sector. Creep-feed grinding is a profile grinding method involving deep depth of cut. This method provides many times higher performance levels than possible with conventional grinding as a result of larger wheel contact arc and an appropriate machine concept. "Simple" creep-feed has long since become a thing of the past. 500 mm/min, for a long time considered as the "sound barrier" has long since been exceeded. Since those days, the field of application has been extended in many directions. The original creep-feed in the X direction (longitudinal table creep-feed) has become a standard.

Depending on the machine design, creep-feed grinding is now accomplished within any axis of movement or combination thereof. A few examples are: Rotary creep-feed, Plunge creep-feed and Cross creep-feed.

All models have been designed with the production environment in mind and feature ultra rigid polymer concrete or Meehanite grade cast iron machine beds giving a small footprint, traditional CNC or Touch screen control options and fully enclosed guarding.

The absence of a reciprocating table and a wheel head column also gives major benefits with respect to structural rigidity and machine dynamics. These machines are primarily employed for grinding the fir tree root profiles of turbine blades and this to a level of accuracy only achieved by machines manufactured from our present modular concept whether these turbine blades are used in an aircraft jet engine, in electricity generating turbines, or gas pumping stations is just a question of tooling and matching of machine size.

Cosmos has further developed the process for using the same machine for oscillating surface grinding where surface finish is critical parameter it could be achievable after creep grinding.

Micro-Granit (Polymer Concrete)

Micro-granit - a new material new materials and alloys are the reason for the last years' out-of-proportion increase in the efficiency of metal working machines. One of the most interesting materials is Micro-Granit (scientific term - 'concrete polymer').

Field trials proved within a short period Micro-Granit's superiority to cast iron machine beds. An ascertainment, which was confirmed by scientific findings of concrete polymer tests, carried out by universities and material research laboratories.

Micro-Granit's most es sential qualities are:

sential qualities are:

- Exemplary damping

- Constant temperature

- Rapid availability, cures in ten hours

- Smooth finished surfaces

- Oil and coolant emulsion resistant

- Low specific gravity results in greater wall thicknesses with the same total weight (as cast iron)

- Generally, there is no need for a foundation, and

- Raised performance through improved general behaviour.

It is precisely this last point, which shows the superiority of Micro-Granit. The following comparable values relate to a cast iron and a Micro-Granit machine.

Grinding was carried out at creep-feed rate with CD on a machine with cast iron bed. The maximum feed rates value achieved was 900 mm/min with 3 mm chip in-feed. Chatter and wheel wear dictated the limits. An absolutely comparable machine with Micro-Granit bed permitted right from the start a table traverse rate of 1800 mm/min using the same in-feed.

The graph shows the influence of the ambient temperature (sudden change in temperature) on a machine bed consisting of Micro-Granit respectively cast iron.

(Cosmos Impex (I) Pvt Ltd, Vadodara. Tel: 0265-3927000. Mobile: 099740-89423. Fax:91-265-3927001. Email: bina@cosmos.in)

amara Raja Group, US$ 500 million (2500cr) diversi fied conglomerate, has unveiled a new identity coinciding with its silver jubilee celebrations. Marking the occasion the group Chairman, Dr. Ramachandra N. Galla announced setting up of Amara Raja Digital World City (ARDWC) and shared group's vision to achieve US $25 billion revenue by 2025 and continue to create non-migratory jobs.

Launching the new identity of the group, Dr. Ramachandra N. Galla, Chairman, Amara Raja Group, said, "Twenty five years ago Amara Raja Group started its journey with a vision of inclusive and sustainable growth in delivering world class products./p>

The group has grown from one company to 7 companies with a turnover of Rs 2500 cr, employing over 7000 people across the country with 12 manufacturing units spread over 4 manufacturing complexes providing non migratory jobs."

Amara Raja Group comprises 7 companies namely Amara Raja Power Systems Limited, Amara Raja Batteries Limited, Mangal Precision Products Limited, Amara Raja Electronics Limited, Galla Foods Limited, Amara Raja Infra Pvt. Ltd. and Amara Raja Industrial Services Pvt.Ltd.

Related Products

Fieldpower Power Bus System

Weidmueller Electronics India offers FieldPower power bus system.

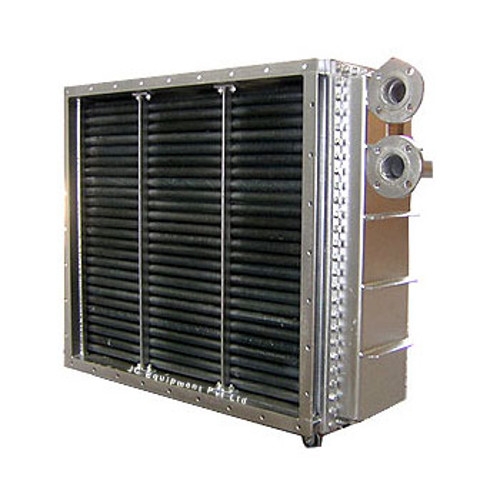

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Ceramic Reinforced Grinding Wheels

Rüggeberg GmbH & Co KG,

PFERD-Werkzeuge, has launched new reinforced grinding wheels with ceramic oxide

grain.