Schedule a Call Back

Cable Extruders Emphasis on Design & Research

Technical Articles

Technical Articles- Mar 04,13

Pune-based Nirman Maschinen Fabrik specialises in designing, manufacturing and installing extrusion lines for cables and the one factor that has put wind in its sails is its complete focus on customization, says Huned Contractor

More than a decade ago when the Indian wire and cable industry was still in a pretty nascent state, Pune-based Vijay Deshpande made a decision that many at that time would have considered immature. He had a steady job then with a company that was making extrusion and wire drawing machines and the future seemed all set. He was 48 years old. However, the bug of entrepreneurism bit him hard and Deshpande quit his job to become an independent designer and manufacturer of cable extrusion machines. He was joined in this effort by Prashant Sawant who was then the general manager of Associated Cables, a company set up in 1973 with its manufacturing facility at Chiplun in Ratnagiri district of Maharashtra to make instrumentation cables, control cables, thermocouple cables and special application cables.

With Deshpande and Sawant setting up Nirman Maschinen Fabrik (NMF) in 2003, the beginning was encouraging enough. "We immediately got about three orders to design, install and commission cable extruders and this sent our confidence roaring upwards," Deshpande says. Since then, NMF has always been active and the biggest factor in the company's advantage is its expertise in the designing domain. "We had never planned to get into a mass manufacturing mindset. Rather, we work on a very one-to-one platform with our clients - understanding their requirements and then creating a custom-made design for the extrusion machine. Once the design is approved, we manufacture it with parts sourced from various vendors. Here too, we pay special attention to the quality of the parts so that the machine will perform as per the standards laid down in our design," Deshpande elaborates.

Some of the clients that NMF has worked with include Aurangabad-based Kiran Cables that manufactures electric cables and wires and Rely Cables, manufacturers of PVC cables, battery cables and automotive cables.

"We are now engaged in a project for Dhoot Transmission Ltd. Established by Rahul Dhoot of the Videocon Group in 1999, Dhoot Transmission has been catering to the evolving needs of the automotive and domestic appliances market, both in India and abroad. Over the last 13 years, the company has emerged as one of the leading Indian manufacturers of wiring harnesses and power cords for this market. "As can be seen from our client roster, we have worked on designing machines that have had to serve widely varying needs even if they all make cables," Deshpande points out.

What has helped NMF create a niche in the highly competitive cable extruders' market is Deshpande's passion for continuous research and development. To this end, he regularly visits wire and cable exhibitions across the world and is particularly fascinated by the event that takes place at Dusseldorf in Germany once every two years. "I am in complete awe of German-make extrusion machines because their designs are flawless and their machines work without any breakdowns or long maintenance downtime. This is mostly because of the huge amount of research that is invested in their products as also the evolving field of metallurgy. Almost every big manufacturer of extrusion machines focuses on developing metals that will help the operation to become smoother, more cost-effective and absolutely efficient," Deshpande points out.

As for the challenges in the sector, Deshpande pins them to just one word - cost. "The Indian cable market has always been in a state of fluctuation. Moreover, there is so much of undercutting in the product prices that companies have to think twice before investing huge amounts by way of capital expenditure.

To give you an example, an entire cable extrusion line could be set up for about Rs 55 lakh by using Indian parts and technology but if one were to source foreign-make parts of excellent quality, a single crosshead would cost as much as the entire line itself. Therefore, it all boils down to economics. The big debate is about sustainability. At the same time, the scenario looks quite bright because of the government's emphasis on infrastructure development. This will give the cable manufacturers good reason to ramp up their capacities," he says.

(Nirman Maschinen Fabrik, A 206, Swagat Residency, Behind Katraj Milk Dairy, Pune - 411 046. Tel: +91-9822009274. Email: nirmanmaschinenfabrik@yahoo.in)

Related Products

Fieldpower Power Bus System

Weidmueller Electronics India offers FieldPower power bus system.

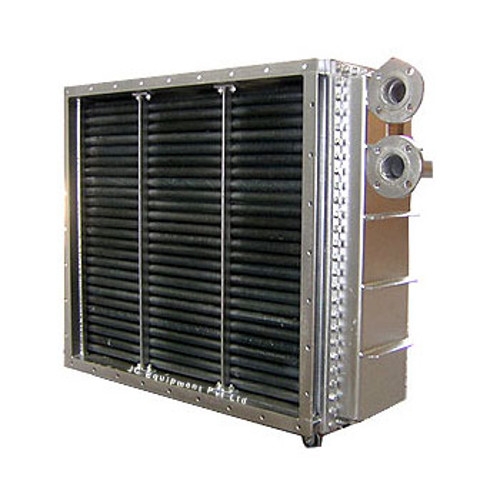

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Ceramic Reinforced Grinding Wheels

Rüggeberg GmbH & Co KG,

PFERD-Werkzeuge, has launched new reinforced grinding wheels with ceramic oxide

grain.