Schedule a Call Back

Bringing World-class Cable Technology to India

Technical Articles

Technical Articles- Aug 16,10

Ravin Cables Limited's joint venture with the Prysmian Group of Italy will help the company bring to the India market new technologies and products, reports Huned Contractor

The year 2010 definitely took off on a bright note for Ravin Cables Limited, one of India's leading manufacturers of Primecab brand low voltage and medium voltage power cables. In January, Ravin Cables Ltd, whose turnover in 2008-09 was Rs 310 crore, announced a joint venture with Prysmian Group of Italy, a world leader in the production of high technology cables required in the energy and telecommunication sectors. Prysmian is a multinational company with 56 manufacturing facilities in 24 countries, seven R&D centres and 12,000 employees. Over the last decade, the company has integrated major partners such as Siemens cable activities and BICC, and it is currently carrying out a worldwide development strategy aimed at further strengthening its presence in high potential growth countries.

The year 2010 definitely took off on a bright note for Ravin Cables Limited, one of India's leading manufacturers of Primecab brand low voltage and medium voltage power cables. In January, Ravin Cables Ltd, whose turnover in 2008-09 was Rs 310 crore, announced a joint venture with Prysmian Group of Italy, a world leader in the production of high technology cables required in the energy and telecommunication sectors. Prysmian is a multinational company with 56 manufacturing facilities in 24 countries, seven R&D centres and 12,000 employees. Over the last decade, the company has integrated major partners such as Siemens cable activities and BICC, and it is currently carrying out a worldwide development strategy aimed at further strengthening its presence in high potential growth countries.

"The reason that the JV was entered into with Prysmian was to have access to world-class technologies and best global manufacturing practices. Ravin Cables is looking forward to becoming a leader in the electrical industry within the next three to five years. The new joint venture is set up in the spirit of continuity with the successful history of Ravin. However, the real big opportunity will be to leverage on the financial robustness, state-of-the-art technologies and know-how and the proven track record of the worldwide industry leader. For customers, this means access to ultimate product design and materials, full reliability of production processes and high standard of quality and services," says Vijay Karia, Chairman and Managing Director, Ravin Cables.

The foundation of Ravin Cables was laid by the illustrious technocrat Pramod Karia in 1950. With its headoffice at Mumbai and a manufacturing facility at Markal near Pune, Ravin Cables became a public limited company in 1994. It was awarded ISO 9002 certification in 1999 and the very next year it achieved an export house status. In 2003, it was declared the largest exporter of power cables and in 2005 the company's turnover crossed Rs 1,000 million. In 2006, it forged an alliance with the ruler of Fujairah, UAE, and in 2007 the turnover crossed Rs 2,500 million. The Fujairah plant was commissioned in 2008. The plant has a production capacity of 5,000 km per annum of power cables, 5,000 km per annum of control cables and 2,500 km per annum of single core wire and flexibles.

With a client roster that includes some of the biggest companies in India such as Eicher Motors, Maruti Udyog, Asian Paints, Reliance Industries, Asea Brown Boveri, Kirloskar Brothers, Siemens Ltd, Gujarat Ambuja Cement, Hindustan Lever, Pepsico India Holdings, Grasim Industries and others, Ravin Cables is now looking forward to multiply its market presence in the coming years with a special focus on high-tech segments. "We will continue to innovate and launch new products and technologies in the market in terms of EHV cables, as well as to supply specialty oil and gas exploration cables. Ravin Cables will also offer huge potential for growth, as well as international exposure to its employees. Our goal is to become India's first 'complete' power infrastructure company," Karia states.

With a client roster that includes some of the biggest companies in India such as Eicher Motors, Maruti Udyog, Asian Paints, Reliance Industries, Asea Brown Boveri, Kirloskar Brothers, Siemens Ltd, Gujarat Ambuja Cement, Hindustan Lever, Pepsico India Holdings, Grasim Industries and others, Ravin Cables is now looking forward to multiply its market presence in the coming years with a special focus on high-tech segments. "We will continue to innovate and launch new products and technologies in the market in terms of EHV cables, as well as to supply specialty oil and gas exploration cables. Ravin Cables will also offer huge potential for growth, as well as international exposure to its employees. Our goal is to become India's first 'complete' power infrastructure company," Karia states.

Elaborating about the capex plans for the future, Karia says, "We will shortly be setting up CCV lines at Pune to manufacture EHV cables up to 220 kV. Power Plus Cable Company LLC, which is a joint venture between Ravin Cables Ltd and the Government of Fujairah in UAE, currently has the capability to manufacture cables up to 220 kV.

In both the plants we are also aiming to introduce specialty oil and natural gas cables as well as other specialised sector specific cables. We shall also be leveraging on Prysmian's worldwide facilities to supply submarine cables, optical fibres, EHV joints & terminations and specialised sector specific cables into the Indian market. All these plants would require a huge amount of capex running into millions of dollars which we shall be spending in the next few years' time."

Another area of focus is to upgrade the quality of products to reduce the T&D losses and increase the safety of the installations. "A safe and definite way to reduce T& D losses and theft of electricity, as well as to increase the safety of the electrical networks, is to use underground cables which are always preferred to overhead bare conductors. The Indian market currently lacks the technology and the R&D base, which we are looking to capitalise on through the expertise of Prysmian. Initiatives have been undertaken to leverage the financial sturdiness and state-of-the-art technologies that Prysmian possesses. Added to that is the fact that Prysmian spends more than Euro 50 million per year on R&D alone and this means that Ravin Cables is sure to benefit with this base," Karia adds.

The fact is that India's market for high voltage cables and systems is expected to grow rapidly, estimated to double in size in the next three years thanks to the country's dynamic economy and the need for rapid development of its power distribution grids. "Given this scenario, our new joint venture's goal is to more than double the turnover by 2012, particularly by developing a mix of higher value-added products," Karia states. Prysmian has acquired a 51 per cent stake in Ravin Cables with the balance remaining in the hands of the current promoters.

Austin Engineering Company, a Profile

Austin Engineering Company, promoted exclusively by first generation technocrats 38 years ago, has been growing with the active support from its esteemed customers. Apart from standardised bearings, it specialises in manufacturing customised bearing. The facilities are located at Junagadh in Gujarat.

The company manufactures the widest range of bearings in India (numbering 4000) covering all major types and configurations/derivatives of anti-friction rolling bearings, viz., ball bearings, cylindrical roller bearings, taper roller bearings, needle roller bearings, spherical roller bearings, etc.

The company manufactures the widest range of bearings in India (numbering 4000) covering all major types and configurations/derivatives of anti-friction rolling bearings, viz., ball bearings, cylindrical roller bearings, taper roller bearings, needle roller bearings, spherical roller bearings, etc.

It endeavours new developments, continuous quality improvement and a strong desire to prove that Indian technology can compete with any toptechnologically advanced countries products, thus resulting in unshakable customer confidence in India and abroad for `aec' bearings. It offers a product-mix, which is totally market driven to create a competitive advantage over other players in the market.

The company, awarded with ISO/TS 16949: 2002 (includes designing of bearings) by TUV Rheinland, Germany, can manufacture at present bearings having bore dia from 10 mm to 1500 mm and outside dia from 20 mm to 1800 mm, weighing from 20 gm to 1000 kg. Much bigger size bearings are under development.

Export Awards: the company is a recipient of Excellent Export Performer Award for 2005-2006. It is also an awardee of Top Export Performer for the year 2006-2007. It is going to receive Star Performer Award for Engineering

Exports for the year 2007-2008. It also has bestowed the Status of Star. Export House. Its current sales consist around 60% towards exports mainly to the USA, the UK, and European countries. It has offices in the USA and Italy.

Defence Import Substitution: the company has developed and supplied since 1988 (and continues to do so) 300 different sizes of bearings to Indian.

Defence establishments. Its considerable R&D efforts involving identifying special materials and establishment manufacturing techniques, and undertaking super special metallurgical and metllographical studies, have paid rich dividends by way of Indian Ministry of Defence becoming self-reliant. These bearings find application in main battle tanks, and other crawler track and rubber-tired military vehicles. It fact, it is not a mere supplier but a partner to the Indian defence services. It manufactures bearings to GOST, DIN, BIS, BS, and AFBMA standards.

The customers are in the segments of steel mills, material handling equipment, agriculture, electrical, gear box, textile machinery, Indian railways, mining, cement, sugar, oil fields, machine tool, spindles, pumps and motors, etc., apart from state road transport undertakings and Indian defence services.

(Contacts: Mr H N Vadgama; Mr J Krishnan, Vice President (Mktg, OEM); Mr Jana Prasad, Vice President (VP - Global Business Development), Austin Engineering Company Ltd, Dist. Junagadh, Gujarat. Tel: 02873-252223, 252267. Fax: 91-2873-252268. Email: hiren.vadgama @aecbearings.com,jk@aecbearines.com, jana.prasad@aecbearings.com)

Related Products

Fieldpower Power Bus System

Weidmueller Electronics India offers FieldPower power bus system.

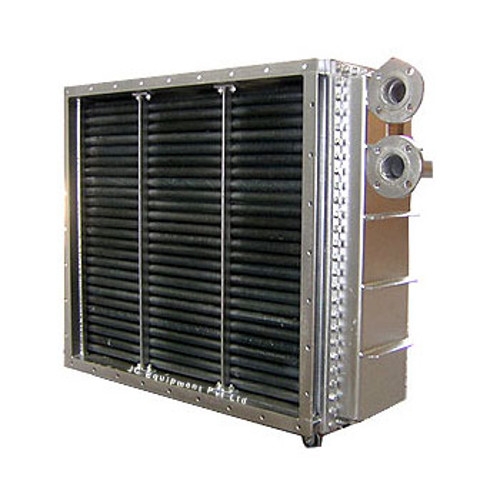

Finned Tube Heat Exchanger

Simon Coil And Heat Exchanger manufacturers

finned tube heat exchangers.

Ceramic Reinforced Grinding Wheels

Rüggeberg GmbH & Co KG,

PFERD-Werkzeuge, has launched new reinforced grinding wheels with ceramic oxide

grain.