Schedule a Call Back

As EV grows, metalworking industry may need to adapt by developing new tech

Articles

Articles- Jan 29,24

Related Stories

Bharat FIH shuts R&D and supply chain subsidiary amid revenue decline

In 2021, Bharat FIH had established two subsidiaries—Bharat Taiwan Corporation and Rising Stars Hi-Tech—to enhance research, product development, and engineering capabilities.

Read more

Schaeffler to lay off 4,700 jobs amid challenges in Europe’s auto sector

Overall, the job cuts will affect around 3.1% of Schaeffler's workforce of 120,000, which increased after its merger with electric powertrain specialist Vitesco.

Read moreRelated Products

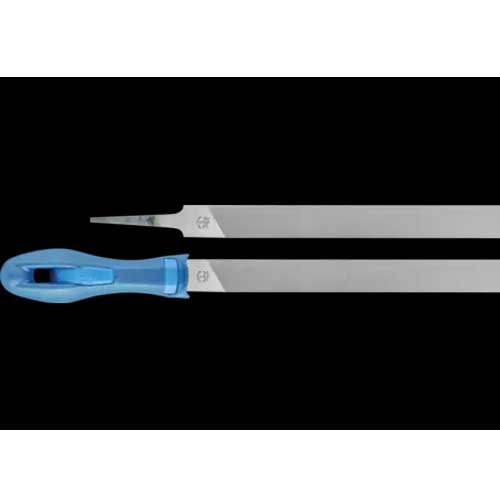

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.

Ss Hex Head Bolts

Trychem Metal And Alloys is offering SS hex head bolt.

Cutting Tools

Get Cutting Tools provides a wide range of CNC cutting tools