Schedule a Call Back

‘Drive’ to solution

Technical Articles

Technical Articles- Mar 01,18

Parker utilises VFD to eliminate the bottleneck experienced in a canning plant

How does one overcome a bottleneck in a food and beverage canning plant? Apply good engineering design and use a variable frequency drive solution. Beverage bottling or canning has always been a complex process, requiring strict control over a number of operating parameters. Accuracy of line speed, liquid flow rate and pressure, temperature, and timing is crucial to maximising output and reducing or eliminating rejected product.

Jam ups result in lost production

Parker was contracted by a beverage packaging facility with a problem. The plant was losing production due to jam ups and inconsistent temperature control of a can warmer line, resulting in rejected product. Not only was the rejected product wasted, but it then had to be destroyed and disposed of at considerable expense. Factoring in lost production time, a jam could cost up to $6000 per incident.

Faced with a 9 month waiting period for major capital approval to replace the line, the maintenance department was instead tasked with upgrading the existing control system. The existing system was over 20 years old, and used fixed speed 'across the line' starters for pump control.

The customer was open to replacing these with variable frequency drives (VFDs) for their better controllability and accompanying energy savings, but physical mounting space would not permit the estimated 80" wide cabinet required for eight conventional drives and the peripheral devices that each separate drive required. Typically each drive requires additional components like line fuses, circuit breaker or disconnect, and an input line reactor. With a limited budget, material and installation cost had to be kept to a minimum.

Engineered benefits of a VFD solution

Parker SSD Drives proposed a variable speed drive system solution to take control of 8 axes of motion on the canning line. It came with a number of benefits:

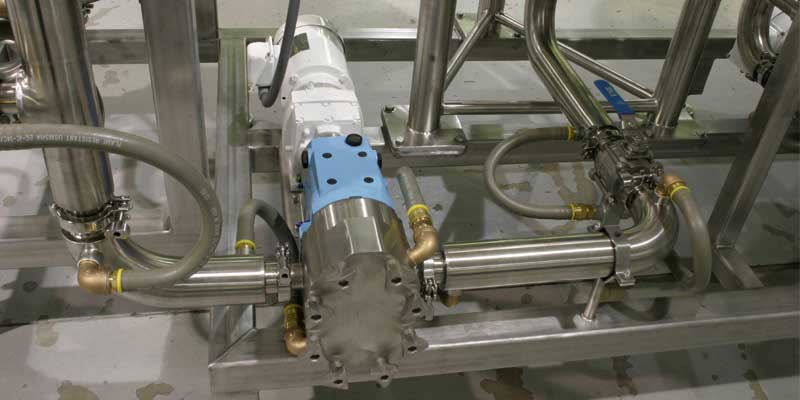

The compact AC890 series, by virtue of its 'bookshelf' design, required much less mounting space than conventional drives.

The common bus design eliminated the need for eight individual line reactors and circuit breakers, requiring only one for the common supply that would feed the lineup of DC input drive modules.

The common bus architecture delivered energy efficiency. When in operation, if one or more of the eight motors is subject to an overhauling load, the resulting regenerated energy will be shared across the DC bus with other drives in the system.

Space savings was realised by the fact that the AC890 has abundant I/O and processor capability on board, eliminating the need for additional PLC equipment. The drive itself would take on the analog and high speedcounter functions.

To communicate with the outside world, one of the available protocols can be selected and installed in the AC890 drive in the form of an option card. In this case, an Ethernet/IP communication card provided compatibility with existing network. The complete system was comfortably fit on a 36" x 60" panel, which was installed in an existing stainless steel enclosure, eliminating the expense of a new one.

Efficient cooling

To efficiently cool the drives, an air-to-liquid heat exchanger was used. Makeup water from the can warming loop was used to supply the heat exchanger, using far less energy than an air conditioner, and having the side benefit of pre-heating the makeup water. This results in less energy used to heat the cans, by capturing waste heat from drives. In addition, advanced features in the AC890 allows the hot water pumps and conveyors to be coordinated for better can temperature control. Line jam-ups, caused by cans getting excessively hot and deforming, were eliminated once the more efficient and better coordinated control system was installed.

Production problem eliminated

In a summary, this system retrofit was successful in eliminating a serious production problem that led to rejected product, and in doing so, also yielded significant energy savings. Due to the compact size and common bus architecture of the AC890, an economical installation was achieved, using no additional plant floor space, and easily tying in to the existing communications network.

For more information contact Parker Hannifin India Pvt Ltd, on Tel: 044-43910799/00 and Email: mitali.nair@parker.com or visit: www.parker.com

Related Stories

WIKA India to display measuring instruments for F&B industry at Anuga FoodTec 24

This helps operating machinery without any breakdowns and gain accurate and reliable measurements for several variables being measured, like pressure, temperature, level, and force.

Read more

Phoenix Contact offers Contactron Speed Starter

In the world of automation, maximum controlling in less space is always in demand. For soft starting, speed variation and direction rotation, a combination of bulky contactors, or VFDs are tradition..

Read more

Rising hygiene need drives demand for sanitary pumps

APAC region (driven by food and beverage industry) is expected to witness high growth in demand for sanitary pumps due to its large population and increasing urbanisation, says Technavio report.

Read moreRelated Products

Automatic Food Snacks Packaging Machine

Grace Food Processing & Packaging Machinery offers

automatic food snacks packaging machine.

Servo Auger Machine

All India Packing Machines offers collar type servo auger machine. Read more

Shrink Tunnel

Vista Technopack Machines offers a range of online shrink tunnel with L sealers. Read more