Schedule a Call Back

Renishaw showcases smart technologies for manufacturing at EMO Hannover 2019

Technical Articles

Technical Articles- Oct 21,19

Related Stories

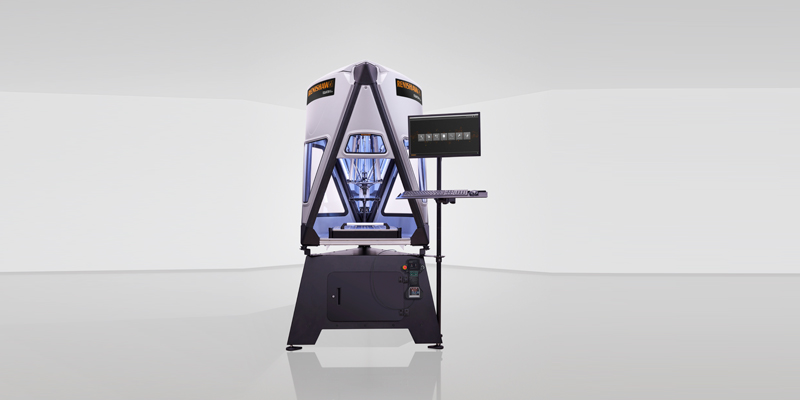

Renishaw Unveils Equator–X 500 Dual-Method Gauging System

Equator–X 500 dual-method system extends the Equator range of versatile gauges for shop floor process control, high-speed measurement and quality assurance

Read more

India needs strong machine tools industry to become a global manufacturing hub

For the Indian manufacturing sector to reach $ 1 trillion, the machine tools industry needs to fire on all cylinders as it enables the production of other machines, parts and equipment for a wide ra..

Read more

Renishaw enables manufacturers to adopt data driven manufacturing: Sanjay Sangam

Renishaw at IMTEX 2025 is coming with a theme ‘Automation for Everyone’, which aims to make advanced automation technologies accessible to a wide range of manufacturers, from small job shops to ..

Read moreRelated Products

Compact Touch Probes for Turning Machines

Blum-Novotest Measuring & Testing Technology Pvt Ltd offers a wide range of compact touch probes for turning machines - TC54-10/TC64-10.

Manual Lathe Chucks

Schunk Intec India Pvt Ltd offers wide range of manual lathe chucks.

Lathe Machine

Bharat Machinery & Spares offers a wide range of gear lathe machine.