Schedule a Call Back

National Capital Region: A model for cluster development

Technical Articles

Technical Articles- Dec 01,17

Even though manufacturing sector participation has declined, it remains as one of the primary employment generators in the overall NCR economy, according to Dr Sangita Singh and Mansi Chaudhary.

The National Capital Region (NCR) is promptly visible as a global economic hub and is now one of the rapidly expanding economic regions in India. The reason why NCR is an essential component of the Indian economy is due to its contribution towards India’s GDP which stood at around 8%.

NCR and its economic edge

The question here arises whether the National Capital Region witnessed balanced development throughout the region or the growth in this region is somewhat skewed? An overview of the comparative data among all constituents of the NCR highlights a stark difference in their growth patterns. The NCR has been subjected to separate stages of evolution since its genesis. In between the 70s to the turn of this millennium, escalated migration into NCT of Delhi posed a challenge to a visible, substantial developmental issue that was how to ensure equitable growth among all the regions of NCR. The fundamental difficulty lies in the fact that growth trend in the NCR till the day is disparate; there is a magnitude of difference within the rate of growth and structure of economic activities across the region that is in much need for stabilisation.

There are glaring differences in the economic structure of different sub-regions. For example, NCT of Delhi is primarily a center for tertiary activities. However, regions such as Uttar Pradesh and Rajasthan are still commanded by primary activities, while Haryana sub-region is an amalgamation of industrial and service sector. Gurgaon district in Haryana sub-region has shown phenomenal growth regarding per capita income, primarily due to rapidly expanding IT and ITES sector, whereas, Panipat district in Haryana is progressing as a major trade center. Alwar district in Rajasthan sub-region, on the other hand, predominantly remains an agriculture economy.

The central weakness in the NCR’s employment performance is the failure of the Rajasthan sub-region to create employment opportunities in manufacturing or service sectors. The existing business environment is unable to support large-scale employment in non-agriculture activities in these sub-regions, although most industrial development in these two sub-regions is in large-scale industries.

Disaggregating at the sector level, the retail trade is not only expanding rapidly within the NCR but is also a significant source of employment after manufacturing sector. Even though manufacturing sector participation has declined, it remains as one of the primary employment generators in the overall NCR economy. Manufacturing is concentrated mainly in cities adjacent to Delhi, especially Faridabad and Gurgaon.

A majority of the worker engaged in the construction sector are located in Delhi (57%) with Rajasthan contributing partly to this industry (4%). Similar trends are seen in trade and commerce sector. A reverse pattern is observed for workers engaged in cultivation and agricultural labourers; NCT of Delhi contributes to only 2% and 3% respectively the most substantial proportion of these workers are concentrated in Haryana and Uttar Pradesh sub-regions respectively.

NCR: Industries and the cluster development approach

Apart from facilitating plethora of economic advantage and employment opportunities for the rural and urban sector in the National Capital Region (NCR), the NCR has also witnessed rapid expansion of specialised industrial clusters. Over the last three decades, there has been a visible rise in the industrial activities within the National Capital Region specifically sub-regions of Haryana, Uttar Pradesh, and Rajasthan.

The Industrial growth taking place at a rapid rate in Delhi provides a strong impetus to adjacent NCR regions such as Gurgaon, Faridabad, Noida, Ghaziabad, etc. National Capital Region hosts large, medium and small enterprises; formal and informal, alike. It is essential to take into accounts the impetuous with which the National Capital Region agglomerations were planned, essentially for industrial development due to their strategic location.

Hence, a certain degree of dynamism and increased level of industrial activity is expected of them.As to improve the competitive advantage of these industries; governments and businesses have revised their policy stance from a sectoral approach towards a cluster-based approach.

There are 600 industrial clusters in India. The NCR itself comprises of more than 60 industrial clusters. Since many clusters in the NCR region are trapped in poverty, declining growth; cluster development approach can become as an essential instrument in their fight to eradicate the fundamental causes of their stagnation. The Table 2 outlines major industrial clusters that persist in the National Capital Region. The NCR clusters are gaining eminence as they are the potential drivers for enterprise development. Cluster development approach itself facilitates a certain degree of dynamism to the industries.

Cluster-based approach for NCR development

Cluster strategy as a notion hails from economic development school of thought. It furnishes a methodological means to foster economic growth. By incorporating a cluster approach as a crucial part of local economic development strategy, development agencies are likely to synchronise their initiatives and evade replication of services. Thus, establishing a comprehensive approach towards economic development. This further helps to set precedence by establishing an inclusive relationship with government. In effect, a more positive business climate is created as existing firms grow and draw new businesses to the region.

Benefits to the cluster

Cluster strategy grants public agencies to direct resources efficiently. Instead of designing innumerable programs to cater to the needs of individual firms, the public effort is focused on meeting the needs of numerous firms with homogeneous issues. The industrial cluster approach gives the public agencies a chance to work first hand with industries and develop business strategies for building a sustainable economy.

How the industry benefit?

A cluster strategy places increment importance to any given industry or cluster and focuses its public as well as private resources in meeting those needs. The industry cluster identifies their chief hindrances and collaborates with public and private entities to cater to the same. Such requirements may incorporate industry-concentrated training programs and forums & meetings convened to address the given needs. How does this help? It preserves effort and time related to identifying all of the appropriate agencies. If a cluster strategy is an essential component of a state-wide policy, the industry has an influential voice in setting a state-wide scheme for economic development.

Advantages offered by NCR to industries and businesses alike Institutions like Development Commissioner (MSME), Delhi Khadi & Village Industries Board (DKVIB), Delhi State Industrial Development Corporation (DSIDC) and Delhi Financial Corporation (DFC) facilitate the promotion of small scale industries in Delhi. Under Craft Sector Promotion Policy, technical guidance, training, marketing support, loans, and grants are provided to the artisans and weavers to increase their sales of handloom and handicraft goods. HSIIDC (Haryana State Industrial Infrastructure Development Corporation) supports industrial, financial and infrastructural activities in Haryana.

As we can see, Haryana, the constituent of NCR, has the maximum number of districts. Haryana Government policies have maximum impact on the development of NCR. Haryana Government has identified the following thrust areas, investment in which will be accorded a priority:

Auto, auto components & light engineering: The upstream and downstream supplier’s opportunities have a great potential to boost the light engineering MSME sector too. Maruti Suzuki plants at Gurgaon and Manesar, Honda two wheeler plant at Manesar and Hero Motorcop’s motorcycle plant at Gurgaon/Dharuhera are the anchors which have facilitated the growth in the automobile and automobile components sector and would catalyse future growth too.

- Agriculture, food processing & allied industry in Karnal and Panipat districts

- Textiles, apparel, knitting and embroidery: Haryana is fourth largest cotton producer in the country, it contributes 6% of the total production of cotton in the country

- Footwear & accessories: Special incentives have been provided to this sector

- Electronics & IT/ITES: Haryana has robust IT software sector which will complement the electronics hardware manufacturing industry. Gurgaon is known as the BPM capital of the world

The proposed projects in Meerut-Muzaffarnagar industrial area like SEZs, food processing zones, integrated townships, etc and Dadra-Noida-Ghaziabad Investment region like free trade warehousing zones, implementation of a power plant, knowledge hubs, integrated townships, biotech hub, integrated logistic hub, etc will further stimulate the growth of industries.

NCR: Growth potential and the way forwards

The 60 industrial clusters within the National Capital Region, today one way or the other are transpiring as priority sectors irrespective of tangible challenges that they face. The service sector, primarily information technology (IT) and IT enable services (ITES), has played an essential part towards the development of the Haryana sub-region.

Some districts like Gurgaon and Faridabad played an essential role in this shift. A majority of the policies are derived from an aggregated calculated investment outlook rather than dynamic integrated planning that will assure optimal resource planning and assure a sustainable growth in the long run. Gurgaon was much in demand for well-connected transport networks that have developed to a somewhat acceptable standard. However, to ensure the long-term viability of such industrial clusters, there is need to establish a support system of power and critical common facilities for micro, small and medium enterprises (MSMEs).

Faridabad is one of the oldest bases for the manufacturing sector in NCR. Sonipat can act as a knowledge center for the NCR such as Food Processing Knowledge Center (NIFTEM) by the Ministry of Food and Processing Unit. Bahadurgarh is the hub for ceramic, glass, chemical, engineering and electrical & electronics industries. Furthermore, government initiatives such as the promotion of the footwear industry and the construction of the Kundli-Manesar-Palwal (KMP) Expressway will have a likely impact on the economic structure of the district. Timely development of logistic infrastructure can come in handy.

The government has also taken the initiative to develop a greenfield activities in R&D of automobile sector. Panipat houses some textile industries; handloom and power loom alike. Panipat is in dire need of common facility centers and also a potential location for a chemical park. There is a need to shift the current MSMEs into an organized as well as a competitive environment. Rewari, an agrarian center, has two crucial industrial growth centers in the district of Dharuhera Industrial Complex and Balwal Growth Center. These locations hold a high potential for the future industrial developments.

In Uttar Pradesh, the government entities are encouraging the development of various manufacturing facilities all across the sub-region. There is potential to promote the district in the areas of nanotechnology, biotechnology, and information technology by further encouraging investment in R&D. Ghaziabad has a very high concentration of industries in Uttar Pradesh. Leading the pack and driving the local economy of Ghaziabad district is financial services, insurance, real estate and business services. The region will benefit greatly from DMIC (Delhi Mumbai Industrial Corridor) with improved logistics and development of highly planned industrial activities. Bulandshahr district is known for its three essential activities - ie agrarian base, milk production and ceramics. Establishing progressive high-tech milk processing plants is the need of the hour to make products like cheese, ghee, and milk powder among others. Here, infrastructure in the form of cold storage chains and food park create appropriate opportunities for the district production base.

The economic structure of NCT Delhi has witnessed profound shift since the 2000s. Primarily due to rapid urbanisation, the agrarian base of NCT of Delhi shrunk, significantly. The critical manufacturing industries in the NCT of Delhi include readymade garments, rubber and plastic products, printing, publishing & reproduction of recorded media, essential metals and fabricated metal products and electrical machinery and apparatus, machinery and equipment. A majority of units are micro, small and medium enterprises. The sustenance system for MSMEs and the informal sector is virtually missing. This calls for the implementation of cluster development programs to cater to the technological and productivity needs as per the Industrial Policy of Delhi.

Rajasthan sub-region, Alwar district’s primary challenge is still its dependence on the agriculture sector. The Delhi Mumbai Industrial Corridor (DMIC) & the master plans underway for the Rajasthan sub-region of NCR by Rajasthan Government are likely to have a significant impact on Alwar’s economic structure. There is need to support local resource-based activities in the region such as the food processing industries, heavy industries that are rapidly becoming non-viable in Gurgaon and Faridabad. An induced cluster-based approach with strong support for infrastructure and other support services will be beneficial for Alwar’s future development in the manufacturing sector. It is anticipated that Alwar will observe the structural change in its economic activities in the next two decades.

(This article is based on the ‘Economic Profile of NCR’ prepared by Apex Cluster Development Services in 2015 for National Capital Region Planning Board, New Delhi)

Dr Sangita Singh is an Associate Professor in Deshbandhu College, Delhi University. She has been teaching economics for the last 30 years. Furthermore, she Guides students on startups and entrepreneurship via an Entrepreneurship Cell, Delhi University.

Mansi Chaudhary is the Director of Apex Cluster Development Services Pvt Ltd. She works as an Economic Development Advisor in different areas of cluster development for the national and international organisations including World Bank, GIZ, and eBay.

For further details, you can contact Mansi Chaudhary on email: mansi.05@hotmail.com

Table 1: Constituents of NCR Delhi

| Sub-region | Name of the districts | Area (in sq kms) |

| Haryana | Faridabad, Gurgaon, Mewat, Rohtak, Sonepat, Rewari, Jhajjar, Panipat, Palwal, Bhiwani (including Charkhi Dadri), Mahendragarh, Jind and Karnal (thirteen districts) | 25,327 |

| Uttar Pradesh | Meerut, Ghaziabad, Gautam Budh Nagar, Bulandshahr, Baghpat, Hapur and Muzaffarnagar (seven districts) | 13,560 |

| Rajasthan | Alwar and Bharatpur (two districts) | 13,447 |

| Delhi | Whole of NCT Delhi | 1,483 |

Source: NCRPB

Table 2: Major industrial clusters in NCR

| District | Industrial cluster |

| Meerut | Auto component, band instrument, glass & wooden bead, mini gas cylinder, power loom/embroidery, rubber product, scissor, sport good, transformer and voltage regulator |

| Ghaziabad | Chemicals and engineering equipment |

| Khurja | Ceramics |

| Noida | Chemicals, auto and engineering item, garment, packaging material and plastic product |

| Alwar | Auto components |

| Delhi | Auto components, chemical, engineering equipment, food product, textiles including garment, packaging material, plastic products, rubber product and sanitary fittings |

| Gurgaon | Automobile and engineering, rubber & chemicals, electronic & electricals and readymade garments, IT and ITES, leather products |

| Panipat | Handloom, Power loom, cotton spinning & shoddy yarn and carpet, iron foundry, rice processing |

| Faridabad | Automobile parts, rubber & chemical, electrical engineering equipment, engineering equipment including auto component and textiles |

| Jhajjar (Bahdurgarh) | General engineering, footwear, ceramic glass and chemical |

| Sonipat | General engineering and chemical, textiles machinery, paint packaging |

| Maneshar | Auto component and IT & ITES |

| Bhiwani | Surgical instruments |

| Karnal | Food processing and packaging |

| Rohtak | General engineering and fastener |

Related Stories

How MNCs are strategising to capture market in India

Today, the Indian MNC scene is changing vastly, with many new ones setting up shop in India. With China becoming less attractive, India is becoming the go to place, writes R Jayaraman and Firoz S Ri..

Read more

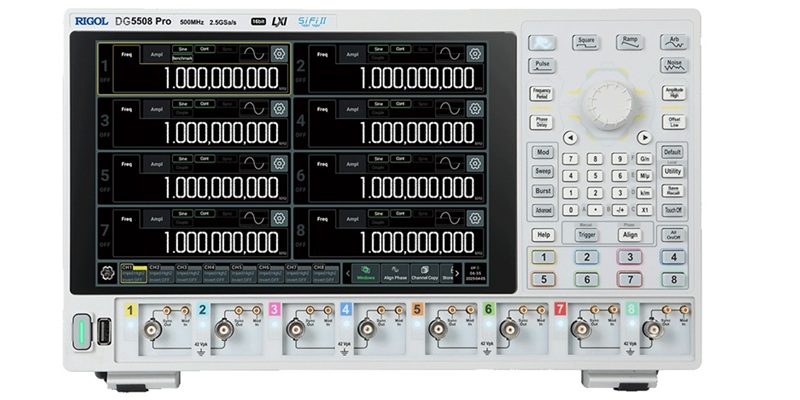

Rigol Technologies Launches DG5000 Pro Series Waveform Generator in India

Rigol Technologies has introduced the DG5000 Pro Series in India, an advanced multi?channel waveform generator with up to 8 isolated channels, 500?MHz output, and high?precision testing features.

Read more

Can the new RDI scheme be a game-changer for R&D in India?

India spends just 0.64 per cent of its GDP on R&D (compared to global average of above 2 per cent). The new Research Development and Innovation (RDI) scheme, with a corpus of Rs 1 trillion, can chan..

Read moreRelated Products

Heavy Industrial Ovens

Hansa Enterprises offers a wide range of heavy industrial ovens.

High Quality Industrial Ovens

Hansa Enterprises offers a wide range of high quality industrial ovens. Read more

Hydro Extractor

Guruson International offers a wide range of cone hydro extractor. Read more