Schedule a Call Back

Machine Tools: The sector glowing with opportunities

Technical Articles

Technical Articles- Jan 01,19

Related Stories

IMTEX Forming celebrates human ingenuity & machine intelligence: Jibak Dasgupta

In this interview with Rakesh Rao, Jibak Dasgupta, Director General & CEO, Indian Machine Tool Manufacturers' Association (IMTMA), explores trends in the machine tools industry and shares some highl..

Read more

IMTEX Forming 2026: Charting the Next Chapter of India’s Metal Forming Ecosystem

IMTEX Forming 2026, Asia’s largest metal forming and manufacturing technology exhibition, is set to return to Bengaluru from 21–25 January 2026.

Read more

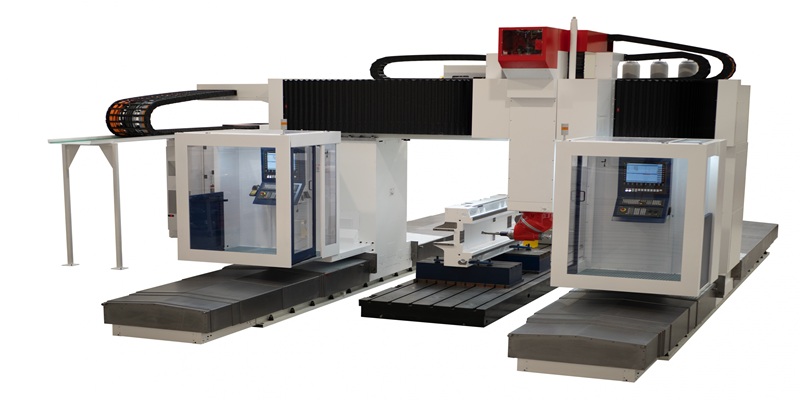

Powermill G3 HPC3 Showcases Italian Excellence in Large-scale Precision Milling

Combining robustness, precision and Industry 4.0 connectivity, the Powermill G3 HPC3 exemplifies Italian manufacturing excellence for large-scale, high-accuracy machining.

Read moreRelated Products

Precision Cutting Tools1

S S Trading Corporation offers a wide range of precision

cutting tools.

Slotting Head Unit for All Cnc Turn Mill Centers

Sphoorti Machine Tools Pvt Ltd offers a wide range of

slotting head unit for all CNC turn mill centers.

Slotted Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of slotted tool disc and tool holders.