Schedule a Call Back

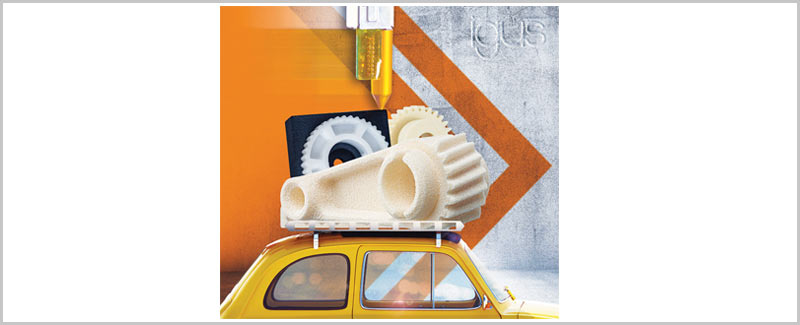

Igus 3D printing service: Low wear plastic parts in 3 days

Technical Articles

Technical Articles- Feb 01,20

Related Stories

3D Printing Strengthens the Foundations of Smart Manufacturing

The global 3D printing market was estimated at $30.55 billion in 2025 and is projected to reach $168.93 billion by 2033, growing at a compound annual growth rate of 23.9 per cent from 2026 to 2033.

Read more

ReBeLMove Pro: Modular robot platform for logistics, assembly and handling

It is based on a compact, rectangular transport robot on four wheels with an electric drive.

Read more

igus Unveils Low-Profile Cable Guide System: No Chain, More Efficiency

igus introduces a new low-profile cable guide system, eliminating the need for traditional energy chains. Ideal for space-constrained and cost-sensitive applications, it ensures safe, efficient cabl..

Read moreRelated Products

Automatic Food Snacks Packaging Machine

Grace Food Processing & Packaging Machinery offers

automatic food snacks packaging machine.

Servo Auger Machine

All India Packing Machines offers collar type servo auger machine. Read more

Shrink Tunnel

Vista Technopack Machines offers a range of online shrink tunnel with L sealers. Read more