Schedule a Call Back

Eldec’s low-frequency technology ensures higher process reliability

Technical Articles

Technical Articles- Feb 01,19

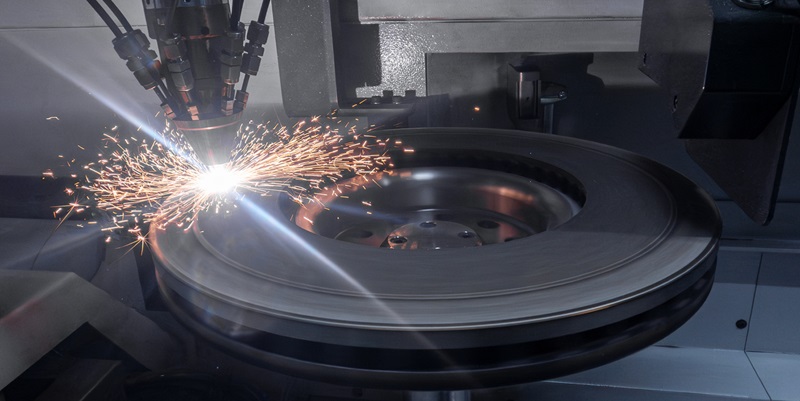

- When using a low frequency of 2 kHz and a process time of five seconds, the desired heating pattern of at least 200°C appears throughout the corona (see Figure).

- If a medium frequency of 12.5 kHz is used, the admissible maximum temperature must be increased to 420°C. Otherwise, the minimum temperature of 200°C will not be reached throughout the corona within the targeted five seconds. However, the higher maximum temperature is not admissible.

- As an alternative, the process time can also be increased when medium frequencies are used. This will nevertheless require a heating time of 8.5 seconds to achieve the desired temperature distribution (without exceeding the maximum temperature).

Related Stories

Low-emission brake disk: Best practice in data-driven production

Eurozone's decision to equip new car models with low-emission braking systems from next year represents a technological leap for the manufacturing industry

Read more

Low-emission brake disk: Best practice in data-driven produc

Eurozone's decision to equip new car models with low-emission braking systems from next year represents a technological leap for the manufacturing industry.

Read more

EMAG’s efficient solution of coating brake discs

EMAG’s solution is economical, suitable for large-scale production, reliable and variable, as a variety of material combinations can be used for coating.

Read moreRelated Products

Power Conversion Systems

POM Systems & Services Pvt Ltd offers a wide range of

PCS power conversion systems energy storage.

Hot Water Generators

Transparent Energy Systems Private Limited offers a wide range of Hot water generators - Aquawarm Superplus.

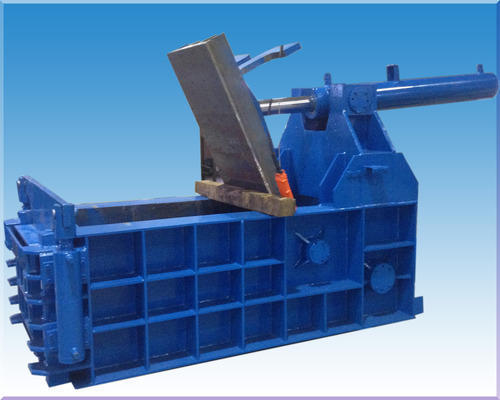

Scrap Baling Press

Fluid Power Machines offers hydraulic scrap baling press. Read more