Schedule a Call Back

EMAG showcases solutions on Industry 4.0 and EV at EMO 2019

Technical Articles

Technical Articles- Nov 01,19

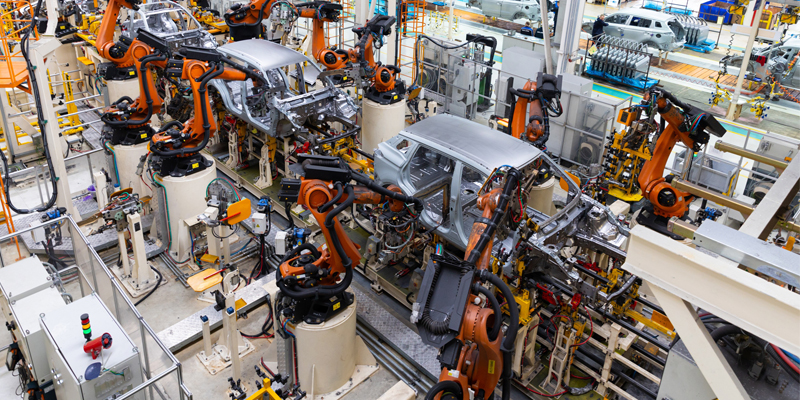

Problems solving requires right tools and the corresponding know-how. Both go hand-in-hand with each other. Thus, EMAG booth at the EMO 2019 – held in September in Germany - featured the latest machine tools and automation solutions.

The know-how required to combine these machines and the technologies of the group’s companies into efficient manufacturing solutions, in the ‘themed areas,’ were entirely dedicated to the production of specific groups of components. Visitors got answers to their questions and they also found the matching manufacturing solution. The offer ranged from single-machine solutions to fully automatic manufacturing lines that are delivered to customers turnkey ready for operation, including the entire development process.

One of the significant topics at the EMAG Group’s technology forum, held in May 2019, was electromobility and its implications for manufacturers and suppliers. There are lots of questions pertaining to manufacturing solutions, components, etc about electric vehicles (EV). EMO visitors found answers to these questions at the EMAG Group’s booth. Visitors came across new components, things such as differentials or brake discs that would be still required regardless of the drive technology implemented. For all these components and many more, EMAG showed the matching solutions and, beyond that, revealed major insights from the 2019 Technology Forum.

True to the EMO motto: Smart technologies driving tomorrow's production networking was another major topic for the EMAG Group at the EMO. It was considered from different perspectives. The ServicePlus app ensures optimal networking between customers and the EMAG service department. Simply scan a QR code on the machine using the app and the user will be able to directly communicate with the service department, request a service callback or directly initiate a spare parts inquiry. The benefits are obvious: On the one hand, EMAG service technicians immediately know which machine is concerned and its exact configuration. On the other hand, users automatically speak to the right contact. The entire communication of the EMAG ServicePlus app takes place on an EMAG-owned server and thus guarantees the highest security standards.

Ongoing developments of the EMAG Group’s Industry 4.0 applications are intended to manage the networking between EMAG machines. In this context, EMAG showed among others how data can be visualised. Using a model, visitors were be able to gain their own impression of how the data flows.

An entirely different type of networking, namely between 17 project partners and the German machine tool builders' association VDW has led to the development of UMTI (universal machine tool interface), which was introduced for the first time at the EMO. A demonstration of the interface standard was shown at EMO and professional visitors were able to get first-hand information about the project.

The EMAG Group showed a whole array of solutions for the most diverse applications at EMO. The corresponding processes stretch from raw parts all the way to final high-precision fine machining - a fact that not least owes to the group’s broad range of technologies.

Related Stories

UNITED GRINDING and GF Machining merge to form UNITED MACHINING SOLUTIONS

The new entity will be one of the world's largest machine tool manufacturers with $ 1.5 billion in sales.

Read more

Low-emission brake disk: Best practice in data-driven production

Eurozone's decision to equip new car models with low-emission braking systems from next year represents a technological leap for the manufacturing industry

Read more

Low-emission brake disk: Best practice in data-driven produc

Eurozone's decision to equip new car models with low-emission braking systems from next year represents a technological leap for the manufacturing industry.

Read moreRelated Products

Angular Head for Vertical Machining Center

Sphoorti Machine Tools Pvt Ltd offers angular head for vertical machining center.

Universal Tapping Machine -model Tr-10/15

Tapping

Machine Tools offers universal tapping machine -model TR-10/15.

Hot Foil Stamping Machine

Friends Engineering Company offers a wide range of hot foil stamping machine.