Schedule a Call Back

Clamping different geometries fast and flexibly

Technical Articles

Technical Articles- Jun 01,18

Related Stories

Hannover Messe 2025 presents battery cell and pack production for EVs

Electric mobility is seen as a key technology for long-term emission reductions – and consequently for a more sustainable future.

Read more

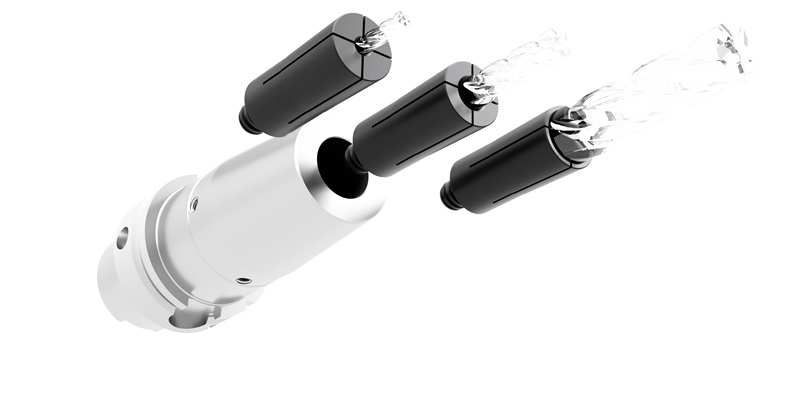

BILZ launches ThermoGrip® TMG Shrink Chuck

The new TMG is characterised by exceptional flexibility, high rigidity and optimised vibration damping.

Read more

Simple Finger Change During an Ongoing Process

With the new jaw quick-change system BSWS-R, SCHUNK enables automated finger changes during an ongoing process. The cleverly designed system consists of just a few components and is compatible with ..

Read moreRelated Products

Carbon Steel Fasteners

Katariya Steel Distributors engages as a manufacturer and supplier of a wide range of carbon steel fasteners.