Schedule a Call Back

Amber increases productivity & product quality using PLM Software

Technical Articles

Technical Articles- Aug 01,18

- • Prevent data duplication and optimise data search and re-use

- • Systematise revision management

- • Streamline drawing release and distribution

- • Facilitate drawing and data sharing with multiple locations

- • Use Teamcenter foundation and engineering process management to manage NX data

- • Leverage the tight integration of Teamcenter with NX

- • Leverage the flexibility and open architecture of Teamcenter

- • Exploit the data management and distribution capabilities of Teamcenter

- • Used improved product development to reduce time-to-market 60 per cent

- • Created better designs to improve product quality by 50 per cent

- • Reduced design time by 60 per cent with seamless coordination and design re-use

- • Achieved 50 percent cost savings

- • Increased overall productivity by 60 per cent

Related Stories

India Sees Slump in Greenfield Projects in Manufacturing: UNCTAD

India has witnessed a significant decline in greenfield manufacturing projects as global foreign direct investment (FDI) dropped in the first half of 2025, with tariff uncertainty exacerbating the s..

Read moreAre IIOT sales strategies holding up adoption of Industry 4.0 in manufacturing?

As Industry 4.0 matures, Industrial IOT (IIOT) platforms will be the backbone of digital transformation. But adoption depends as much on how they are sold as on what they deliver, write R Jayaraman ..

Read more

The data centre market growth and strategies to capture market share in India

India’s data centre market is on a steep upward trajectory, with a growth rate of 21 per cent annually, driven by cloud adoption, digitalization, and an explosion in data consumption. Being an eme..

Read moreRelated Products

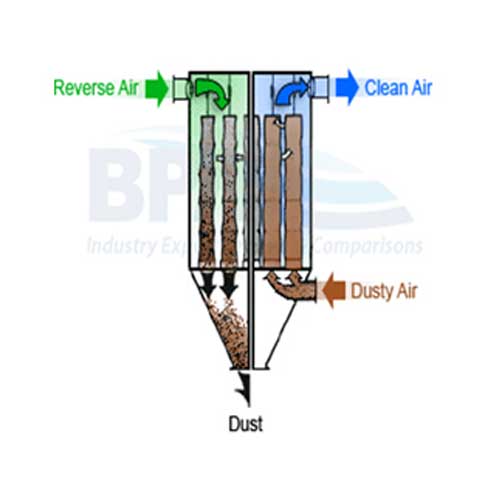

Reverse Air Bag House

ABR Enviro Systems offers a wide range of reverse air bag house.

High Quality Air Knife System

Superchillers offers high quality air knife system. Read more

Compact Cylinders -Vadvu Series

Vijay Air Control offers a wide range of compact cylinders -Vadvu Series