Schedule a Call Back

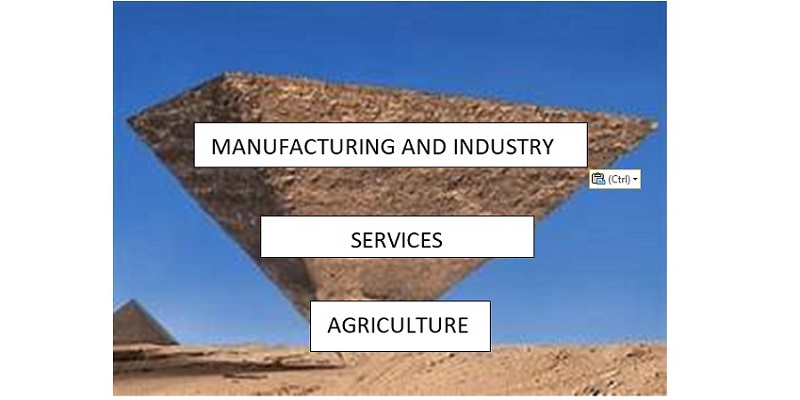

How MSMEs will play a key role in the development of Indian manufacturing sector

Articles

Articles- Dec 12,24

Related Stories

Bharat Forge and Agile Robots sign MoU to Advance AI-Led Industrial Automation

The MoU brings together Bharat Forge’s manufacturing expertise and Germany-based Agile Robots’ AI-led robotics capabilities to accelerate intelligent automation across key civilian industrial se..

Read more

The role of risk management in large projects

Risk is inseparable from project management, particularly in large and long-duration projects, where inadequate risk identification, ownership and follow-up often lead to cost and time overruns. Pra..

Read more

EV shift, trade pressures threaten India’s auto components: Tushar Bhaskar

India’s auto component industry faces mounting risks as EV-led technology shifts, trade pressures, and critical material dependence threaten its global competitiveness.

Read moreRelated Products

Fanless Industrial Pc for Smart Manufacturing

CONTEC Launches BX-M4600 Series - Fanless Industrial PC for Smart Manufacturing.