Schedule a Call Back

SWTS leverages digital DNA to meet India’s energy production needs

Articles

Articles- Aug 28,19

Related Stories

Mitsubishi Heavy Industries reports record FY2024; Issues strong FY2025 outlook

Strong performance was led by the Energy Systems segment, particularly Gas Turbine Combined Cycle (GTCC) and Aero Engines, both of which saw substantial demand and improved margins.

Read more

BrahMos missile factory to be inaugurated in Lucknow on May 11

The BrahMos missile is produced by BrahMos Aerospace, a joint venture between India and Russia. The inauguration comes at a time of heightened military tensions with Pakistan, marked by cross-border..

Read more

India and Chile Sign Terms of Reference for CEPA negotiations

The CEPA aims to build upon the existing PTA between the two nations and seeks to encompass a broader range of sectors, including digital services, investment promotion and cooperation, MSME, critic..

Read moreRelated Products

Power Conversion Systems

POM Systems & Services Pvt Ltd offers a wide range of

PCS power conversion systems energy storage.

Hot Water Generators

Transparent Energy Systems Private Limited offers a wide range of Hot water generators - Aquawarm Superplus.

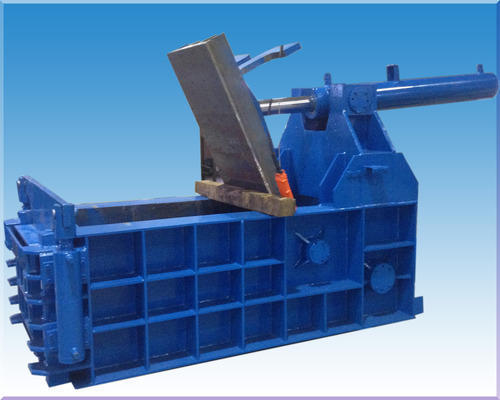

Scrap Baling Press

Fluid Power Machines offers hydraulic scrap baling press. Read more