Schedule a Call Back

Igus presents new low-cost energy chain E4Q.64L, saves upto 20% costs

Industry News

Industry News- Aug 30,23

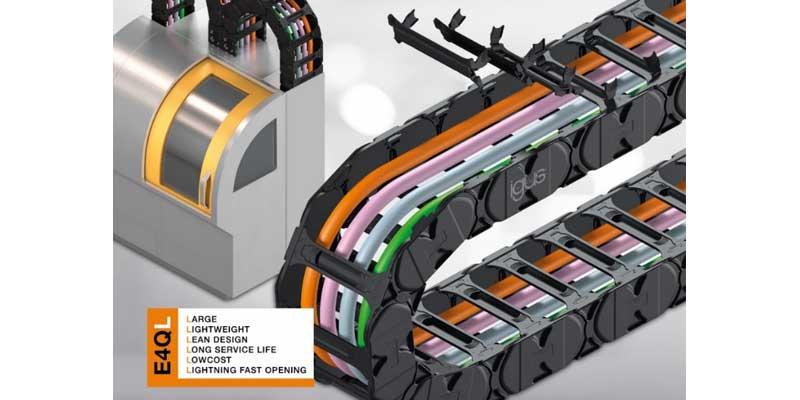

From the seventh robot axis in linear robot applications to machine tools, the igus E4Q-series energy chain has established itself in recent years in demanding applications with large unsupported lengths and high fill weights. There are two reasons for this. One is that the e-chain's wide side links and four stop-dogs per chain link make it very robust. The other is that assembly time is reduced by up to 40 per cent because the crossbars can be opened in seconds - without tools and with just two fingers. The problem is that, in applications with medium loads (machine tools, woodworking, car washes etc), the E4Q is oversized. "To offer users the advantages of the E4Q in these applications as well, and at a lower price, we developed the L version - the E4Q.64L," says Christian Ziegler, Head of e-chain Product Management at igus. "Depending on the width, the low-cost version of the energy chain costs between 15 per cent and 20 per cent less than the E4Q."

Bionic design ensures low weight, and three stop-dogs per chain link guarantee robustness

To reduce costs, the igus designers have modified the E4Q's design. The aim was to strike a balance between low dead weight and maximum robustness. The side links are narrower than those of the E4Q, reducing the weight. The bionic design, which dispenses with any material that has no load-bearing function, was retained. "The stop-dog system was completely rethought. Development goals were more strength and service life than the predecessors with two stop-dogs per chain link. The E4Q.64L is the first igus energy chain with three stop-dogs per chain link," says Ziegler. "This ensures an even more regular power flow and a longer service life."

Up to 20 per cent more unsupported length

Tests in the igus test laboratory prove that the E4Q.64L has an approximately 30 per cent greater breaking moment than the 14240 series, which is also used for unsupported applications. This results in up to 20 per cent more length with the same fill weight. At 4kg/m, for example, the E4Q.64L manages 3.2 metres. The previous models (E4/light and E4.1) managed just 2.7 metres. Ziegler says, "The E4Q.64L's outstanding strength enables us to serve many applications, such as car washes and airport passenger boarding bridges, more cost-effectively than ever before." The optimised ratio of internal to external dimensions ensures enough space for power and data cables. The E4Q.64L's inner height is 64mm. The chain can also be operated in two bending directions by replacing the outer link with a special RBR link. This gives it what is known as a reverse bend radius (RBR), which means that circular movements can be implemented (on a robot's axis 1, for instance).

As adaptable as a chameleon: widths between 100 and 500 millimetres available

With all design adjustments, igus has not changed the E4Q's crossbars in the low-cost version. This ensures two advantages for users. One is that the E4Q.64L can be opened just as easily and intuitively as its big brother. There are two indentations in the crossbars that allow the locking hooks to be opened with two fingers. Unlocked on both sides, the crossbar can be lifted out with little effort. The other advantage is that an extensive product range of crossbar widths is directly available, so that the E4Q.64L has been offered in 29 widths between 100 and 500 millimetres since the start of market launch.

Related Stories

igus Unveils Low-Profile Cable Guide System: No Chain, More Efficiency

igus introduces a new low-profile cable guide system, eliminating the need for traditional energy chains. Ideal for space-constrained and cost-sensitive applications, it ensures safe, efficient cabl..

Read more

Igus expands readycable portfolio with new cables for industrial camera tech

Ready-to-connect, durable and tested cables with Keyence plug-in connectors increase the reliability of vision systems.

Read more

Igus' readychain eco-rack saves 88% of lorry transport volume

The new rack for energy chain systems saves 88 per cent of lorry transport volume, optimises the use of lorries' loading areas and reduces forwarding costs.

Read moreRelated Products

Rubber Sheets Material

Talbros Sealing Material Pvt Ltd offers a wide range of rubber sheets materi Read more

Rail Rubber Pad

Chamunda Enterprise offers a wide range of rail rubber pad.

Insulation Polyester Film

TMA International Private Limited offers a wide range of insulation polyester film.